This step by step diy woodworking project is about hall table plans. This article features detailed plans for building a beautiful hall table with three spacey drawers. Adjust the size and the design of the console table to match your requirements. Work with good judgement and don’t forget to take a look over the rest of the related plans, as there are many designs and woodworking projects to select from.

Work with attention and don’t forget that a good planning will save you from many issues and it will keep the costs withing the total budget. Invest in high quality materials, such as pine, redwood or cedar. Drill pocket holes before inserting the galvanized screws, to prevent the wood from splitting. Add waterproof glue to the joints, in order to enhance the rigidity of the structure. See all my Premium Plans HERE.

Projects made from these plans

Hall Table Plans

Cut & Shopping Lists

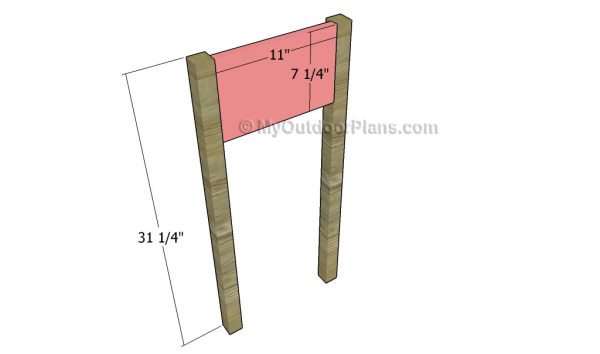

- A – 4 pieces of 2×2 lumber – 31 1/4” long LEGS

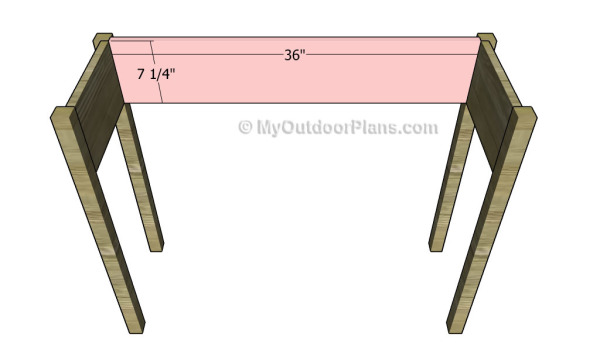

- B – 2 pieces of 1×8 lumber – 11″ long, 1 piece – 36″ long FRAME

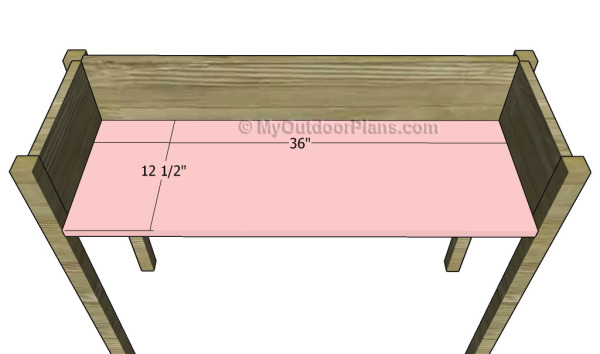

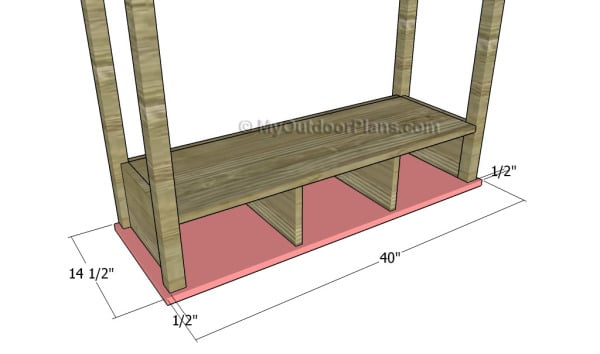

- C – 1 pieces of 3/4″ plywood – 12 1/2″ x 36″ long, 1 pieces of 3/4″ plywood – 14 1/2″ x 40″ long BOTTOM

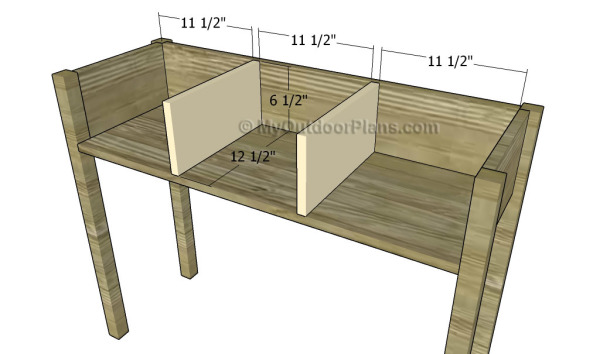

- D – 2 pieces of 3/4″ plywood – 6 1/2″ x 12 1/2″ long PARTITIONS

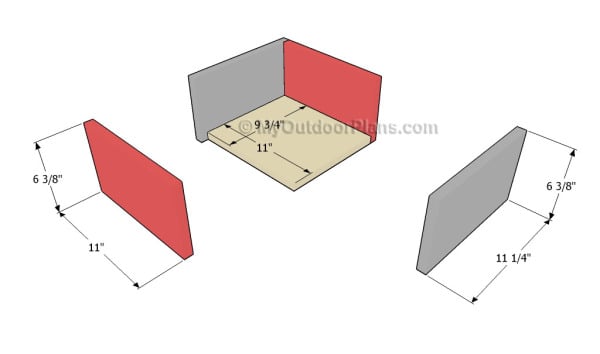

- E – 2 pieces of 3/4″ plywood – 6 3/8″x11″ long, 2 pieces – 6 3/8″x11 1/4″ long, 1 piece – 9 3/4″x11″ long 3xDRAWERS

- 1 piece of 3/4″ plywood – 4’x8′

- 1×8 lumber – 6 ft

- 2 pieces of 2×2 lumber – 8 ft

- 2 1/2″ screws

- 1 1/4″ screws

- wood putty, wood stain

Tools

![]() Hammer, Tape measure, Framing square, Level

Hammer, Tape measure, Framing square, Level

![]() Miter saw, Drill machinery, Screwdriver, Sander

Miter saw, Drill machinery, Screwdriver, Sander

Time

![]() One day

One day

Related

Building a hall table

Building the sides

The first step of the woodworking project is to build the sides of the hall table. As you can easily notice in the diagram, we recommend you to build the legs out of 2×2 lumber and the panel out of 1×8 lumber.

Drill pocket holes at both ends of the slats and secure them to the legs using 1 1/4′ screws and waterproof glue. Make sure the corners are right-angled and leave no gaps between the components.

Assembling the frame

The next step of the woodworking project is to lock the two sides together, by fitting the back component. Cut the it out of 1×8 lumber and drill pocket holes at both ends and along the top edge. Make sure the edges are flush, the corners square and leave no gaps between inserting the galvanized screws.

In order to get a professional result, you have to build the bottom of the hall table out of 3/4″ hardwood plywood. Mark the cut lines on the sheet and get the job done with a circular saw. Smooth the cut edges with fine-grit sandpaper and remove the residues.

Drill pocket holes along the sides of the component, as well as along the back edge. Fit the bottom to the structure and secure it into place using 1 1/4″ screws and glue.

Fitting the partitions

Build the partitions out of 3/4″ plywood at the right dimensions and drill pocket holes along the bottom, top and back edges. Align the components with great care and secure them to the structure using 1 1/4″ screws. Add glue to the joints and remove the residues.

Fitting the top component

Build the tabletop out of 3/4″ plywood and smooth the edges with fine-grit sandpaper. Lay the component on a level surface and center the structure to it. Make sure the back edge of the table is perfectly aligned with the back edge of the tabletop.

Insert 1 1/4″ screws through the legs and frame into the tabletop, in order to create a rigid bond between the components. Add glue to the joints and remove the excess.

Building the drawers

Next, build the build the drawers for the hall table. As you can easily notice in the diagram, we recommend you to build the components out of 3/4″ plywood. Mark the cut lines on the sheets and get the job done with a circular saw.

Drill pocket holes at both ends of the side components and secure them to the perpendicular ones with 1 1/4″ screws. Drill pocket holes along the edges of the bottom and secure it to the sides with screws.

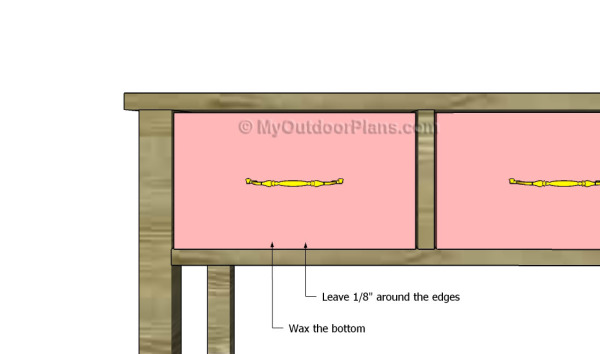

Fitting the drawers

Wax the bottom of the drawers thoroughly and fit them into the opening. Attach the handles and make sure they open and close easily. Leave even gaps on all sides, when sliding in the drawers.

Hall table plans

One of the last steps of the woodworking project is to take care of the finishing touches. Therefore, fill the pilot holes with wood putty and smooth the surface with 120-grit sandpaper.

Top Tip: If you want to enhance the look of the woodworking project and to protect the stand from decay, we recommend you to cover the components with paint or stain. Fit the hall table to the appropriate room and make it the centerpiece.

This woodworking project was about hall table plans. If you want to see more outdoor plans, we recommend you to check out the rest of our step by step projects. LIKE us on Facebook and Google + to be the first that gets out latest projects and to hep us keep adding free woodworking plans for you.