This step by step diy project is about screened gazebo plans. I have designed these plans so you can built a 12×12 gazebo with screens in one week, without much effort. This gazebo may look intimidation at first, but my step by step instructions and detailed diagrams will guide you through the process. In addition, the gazebo has a gable roof so you can frame it easily. Take a look over the rest of my woodworking plans, if you want to get more building inspiration.

When buying the lumber, you should select the planks with great care, making sure they are straight and without any visible flaws (cracks, knots, twists, decay). Investing in cedar or other weather resistant lumber is a good idea, as it will pay off on the long run. Use a spirit level to plumb and align the components, before inserting the galvanized screws, otherwise the project won’t have a symmetrical look. If you have all the materials and tools required for the project, you could get the job done in about a day.

Projects made from these plans

It’s that easy to build a screened gazebo!

Screened Gazebo Plans

Building-a-screened-gazebo

Cut & Shopping Lists

- A – 2 pieces of 2×6 lumber – 144″ long, 12 pieces – 141″ long, 2 pieces – 14 1/2″ long FLOOR FRAME

- B – 7 pieces of 4×4 lumber – 96″ long, 2 pieces – 133″ long POSTS

- C – 27 piece of 2×6 lumber – 144″ long DECKING

- D – 2 pieces of 2×6 lumber – 144″ long, 2 pieces – 141″ long TOP RAILS

- E – 2 pieces of 2×4 lumber – 42 1/4″ long, 6 pieces – 65 1/4″ long, 4 pieces of 2×2 lumber – 42 1/4″ long, 12 pieces – 65 1/4″ long RAILS

- F – 132 pieces of 1×4 lumber – 36″ long BALUSTERS

- 7 pieces of 4×4 lumber – 8′

- 2 pieces of 4×4 lumber – 12′

- 45 piece of of 2×6 lumber – 12′

- 7 pieces of 2×4 lumber – 8′

- 14 pieces of 2×2 lumber – 8′

- 66 pieces of 1×4 lumber – 6′

- tube form, post anchor

- structural screws for connectors

- strong tie T

- 50 pieces of 3 1/2″ lag screws

- 500 pieces of 2 1/2″ screws

- 100 pieces of 2 1/2″ pocket screws

- 2″ brad nails

- wood glue, stain/paint, wood filler

Tools

![]() Hammer, Tape measure, Framing square, Level

Hammer, Tape measure, Framing square, Level

![]() Miter saw, Drill machinery, Screwdriver, Sander

Miter saw, Drill machinery, Screwdriver, Sander

![]() Concrete mixer, Post hole digger

Concrete mixer, Post hole digger

Time

Related

- PART 1: Screened gazebo plans

- PART 2: How to make gazebo screens

Building a screened gazebo

Laying-out-the-gazebo

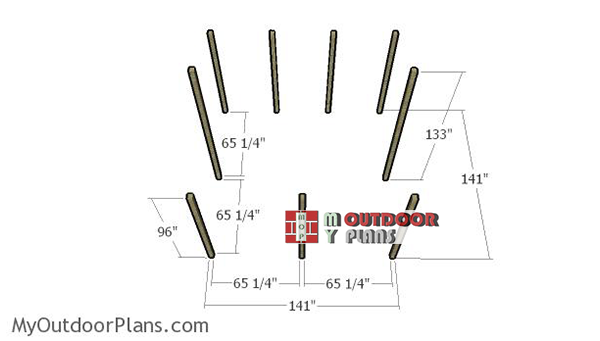

The first step of the woodworking project is to lay out the gazebo in a professional manner. Build batter boards and use string to layout everything in a professional manner. Apply the 3-4-5 rule to every corner and make sure the diagonal are equal, otherwise the corners won’t be square.

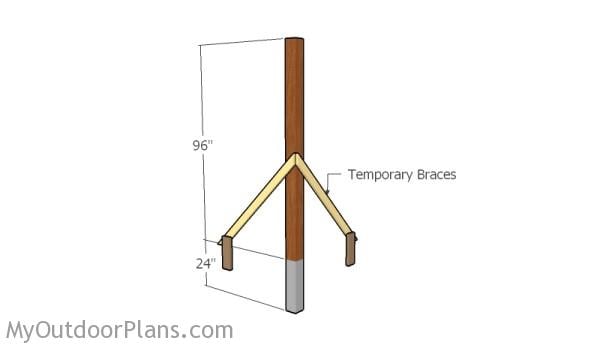

Fitting the posts

You can set the posts in concrete (about 3′ deep – make sure you read the local building codes for accurate information) or you can pour footings and use posts anchors. If you live in an area affected by hurricanes, it would be better to set the posts in concrete.

Use a post hole digger to make 15″ holes in diameter and 3′ deep. Pour a 2″ layer of concrete on the bottom of the holes so you level them. Fit the tube forms and then the 4×4 posts. Use a spirit level to make sure the posts are plumb and then secure them temporarily into place with braces. Fill the tubes with concrete and let it dry out as shown on the bags.

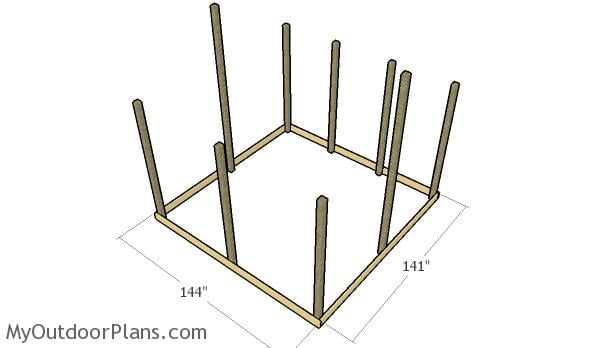

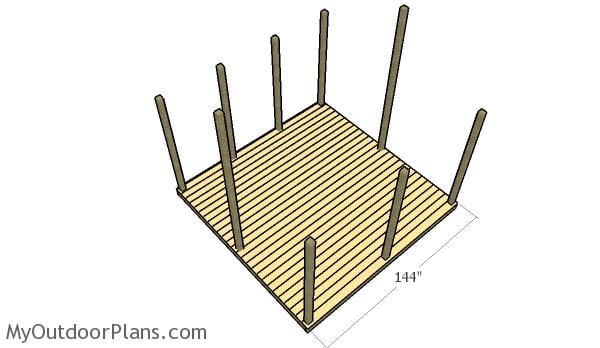

Framing the floor of the gazebo

Fit the 2×6 rim joists to the exterior of the posts. Use a spirit level to make sure the beams are perfectly horizontal. Align the edges before drilling pilot holes and inserting the 3 1/2″” lag bolts.

Fitting-the-joists

Next, you need to attach the regular joists to the floor frame. Make sure you place the joists every 16″ on center for a professional result. Use joist hangers or drill pilot holes through the rim joists and insert 3 1/2″ screws into the regular beams. Make sure the corners are square before inserting the screws.

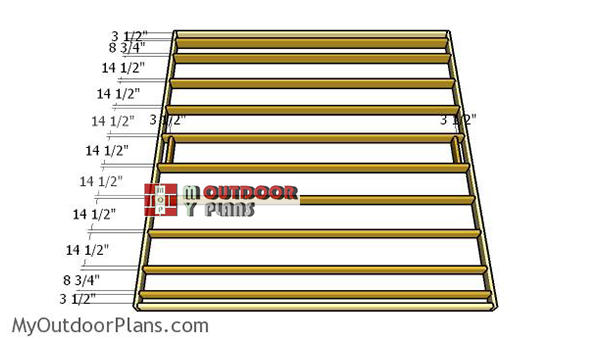

Fitting the decking

Continue the project by fitting the 2×6 decking boards to the floor frame. As you can notice in the diagram, you need to make a few notches to the boards that go around the posts, so they can fit into place. Drill pilot holes through the decking boards and insert 2 1/2″ screws into the joists. Leave no gaps between the boards and align the ends till the edges are flush.

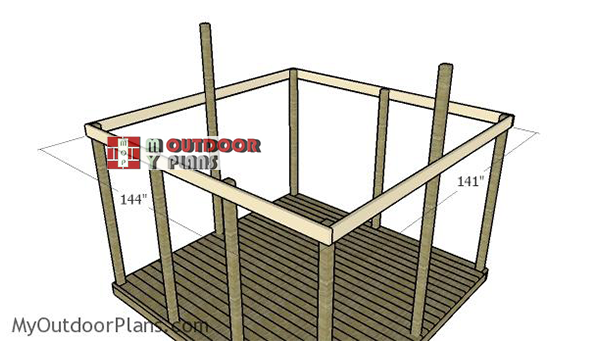

Fitting-the-top-rails

Attach the 2×6 rails to the top of the posts. Clamp the beams to the posts and use a spirit level to make sure the components are horizontal. Drill pilot holes and secure the beams into place with 3 1/2″ lag screws.

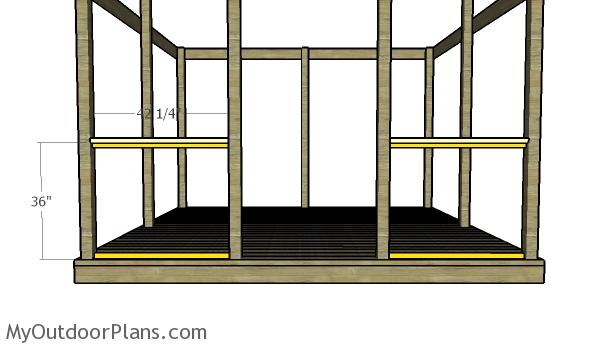

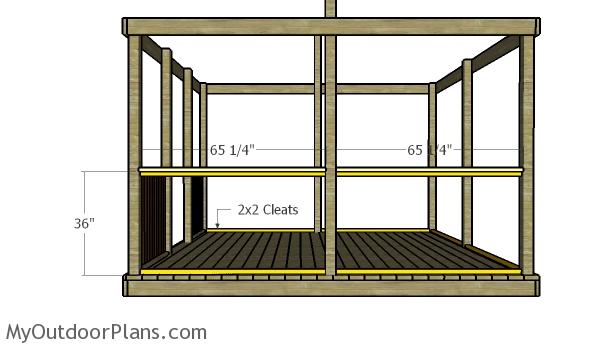

Building the front rails

Next, you need to fit the handrails and the cleats to the gazebo. Use 2×4 lumber for the handrails. Drill pocket holes at both ends of the handrails and secure them to the posts with 2 1/2″ screws. Make sure the corners are square and leave no gaps between the components. Fit the 2×2 cleats to the tom and bottom of the railings.

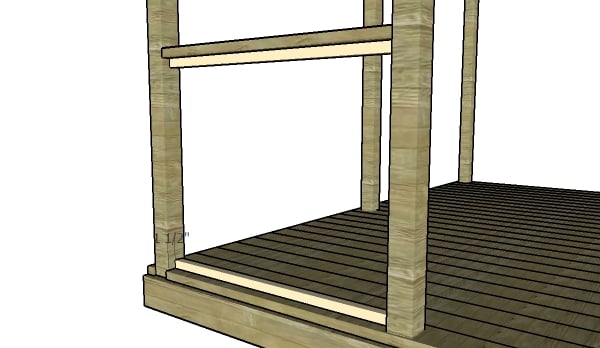

Fitting the cleats – Detail

Another diagram with the cleats, so you have a better understanding on how you should fit the cleats into place.

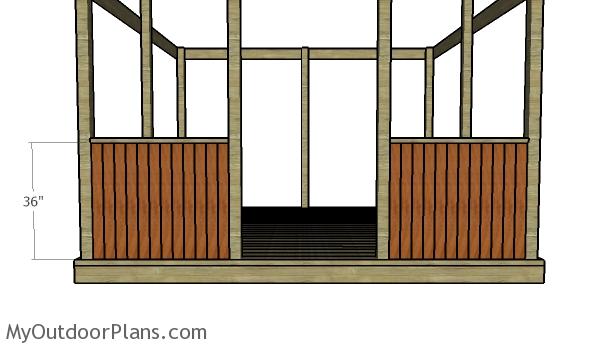

Fitting the front slats

Next, fit the 1×4 slats to the cleats. Use 2″ brad nails to secure the slats into place, as shown in the plans.

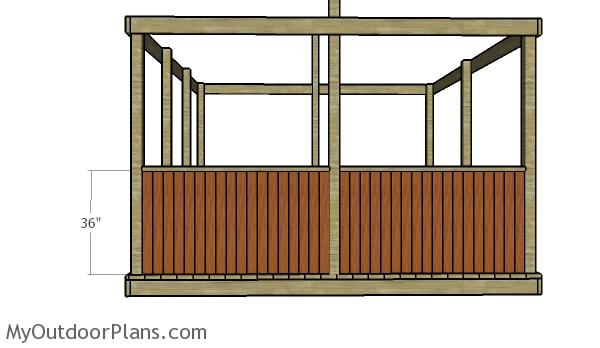

Building the side and back rails

Fit the handrails and the cleats to the sides and to the back of the gazebo. Use a spirit level to make sure the rails are horizontal.

Fitting the side slats

Fit the 1×4 slats to the sides and to the back of the 12×12 gazebo. Use 2″ brad nails to secure the slats to the cleats.

Screened gazebo plans

Make sure you take a look over PART 2 of the project, so you learn how to frame the roof of the gazebo. In addition, I will show you how to build the screens and how to secure them into place. A screened gazebo combines the convenience of an outdoor structure with the benefits of the mesh windows, that protects you from insects and mosquitoes.

12×12 Gazebo Plans

This screened 12×12 gazebo is a moderately complex project. If you have a handy friend, I don’t see why you shouldn’t be able to assemble everything in one week. Remember that you need to adjust the size of the components so they suit your particular own needs and you have to check the local building codes before starting the building process. Check out the rest of the project for free plans and instructions on how to build the roof and the screens.

To get the plans in one PDF file with 1 Cut list and 1 Shopping list. check out the GET PDF PLANS button bellow.

This woodworking project was about screened gazebo plans free. If you want to see more outdoor plans, check out the rest of our step by step projects and follow the instructions to obtain a professional result.