This step by step diy woodworking project is about dog feed station plans. If you want to learn more about building a dog bowl stand, we recommend you to pay attention to the instructions described in the article. Work with good judgement and take a look over the rest of the animals projects featured on our website, as there are so many other projects and designs to choose from. This project will keep the food bowls raised from the floor so your kitchen will be more tidy. In addition, your favorite pet will find drinking water and eating a lot easier and put less effort into it.

There are many plans and designs to choose from, so make sure you take a close look over the rest of the table plans featured on our website. Plan everything with attention and adjust the size and the shape of the patio table to suit your needs. Plumb the legs and make sure the corners are right-angled before inserting the galvanized screws into place. Drill pilot or pocket holes to prevent the wood from splitting. See all my Premium Plans HERE.

Projects made from these plans

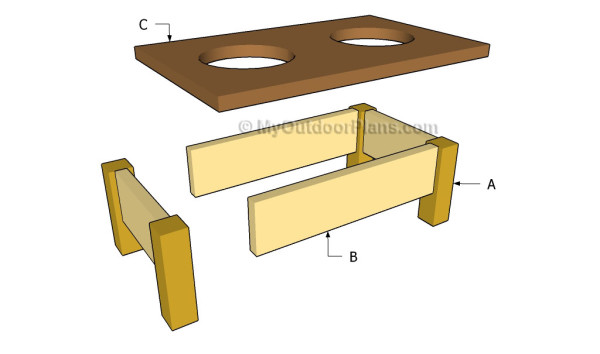

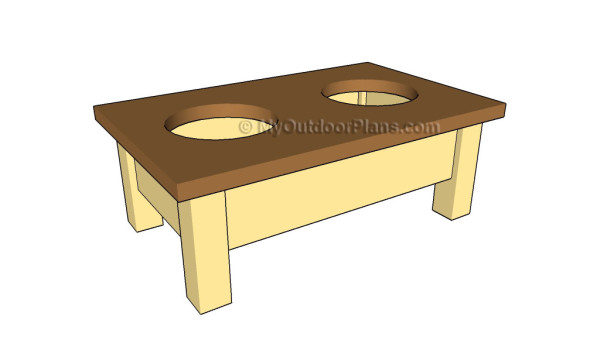

Dog Feed Station Plans

Building a feed station

Cut & Shopping Lists

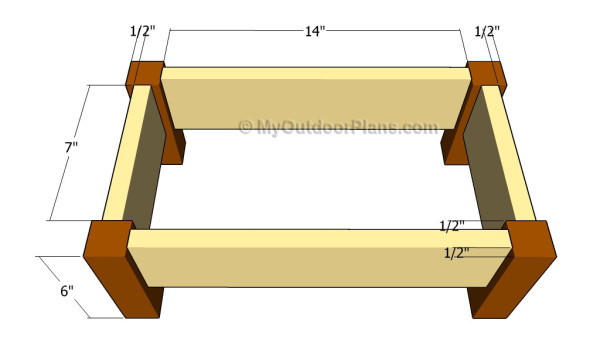

- A – 4 pieces of 2×2 lumber – 6″ long LEGS

- B – 2 pieces of 1×4 lumber – 7″ long, 2 pieces – 14″ long SUPPORTS

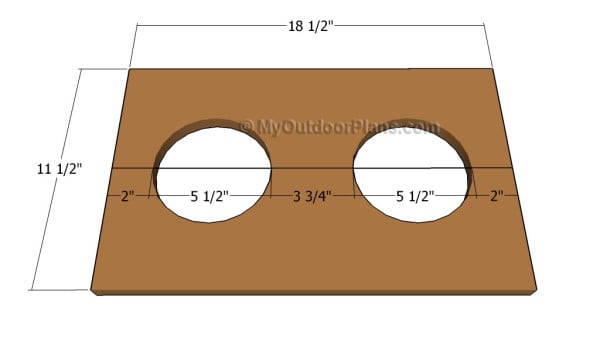

- C – 1 piece of 1×12 lumber – 18 1/2″ long TOP

- 1 piece of 2×2 lumber – 2′

- 1 piece of 1×4 lumber – 4′

- 1 piece of 1×12 lumber – 2′

- dog bowls

- 1 1/4″ screws

- stain

Tools

![]() Hammer, Tape measure, Framing square, Level

Hammer, Tape measure, Framing square, Level

![]() Miter saw, Drill machinery, Screwdriver, Sander

Miter saw, Drill machinery, Screwdriver, Sander

![]() Post hole digger, Concrete mixer

Post hole digger, Concrete mixer

Time

Related

Building a feed station

Building the frame of the dog feeding station

The first step of the woodworking project is to build the frame of the dog feed station. Therefore, cut the legs of the station out of 2×2 lumber and attach the 1×4 supports. Take accurate measurements and cut the components at the right size by using a nice circular saw.

Drill pocket holes at both ends of the supports and lock them to the legs, by using 1 1/4″ galvanized screws. Add glue to enhance the rigidity of the structure. Make sure the corners are square before inserting the screws.

Building the top component

Continue the woodworking project by building the top of the dog feeding station. Mark the lines with a pencil and drill starting holes. Use a nice jigsaw to make the round cuts. Smooth the cut edges with sandpaper and remove the residues, before attaching it to the frame. Make sure you adjust the size of the holes, so that you can fit the bowls quickly. Make sure the holes are centered the to piece of wood.

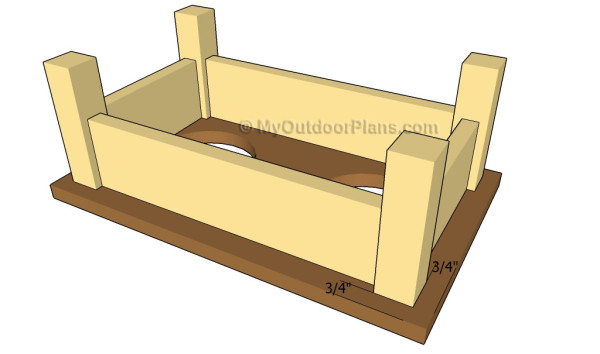

Attaching the top

The next step of the woodworking project is to attach the top component is to the frame of the feed station. As you can easily notice in the plans, we recommend you to drill pocket holes through the supports. Drill the pocket holes along the inside faces of the frame.

Center the frame of the feed station to the top components and insert 1 1/4″ galvanized screws. Add glue to enhance the rigidity of the structure and let it to dry out for several hours. Alternatively, you can add glue to the joints and insert 2″ brad nails from the top into the base.

Dog feeding station plans

One of the last steps of the woodworking project is to take care of the finishing touches. Therefore, fill the pilot holes with wood putty and smooth the surface with 120-grit sandpaper.

Top Tip: If you want to enhance the look of the woodworking project and to protect the table from decay, we recommend you to cover the components with paint or stain. Place the station in a proper location and move it whenever necessary.

This woodworking project was about dog feed station plans. If you want to see more outdoor plans, we recommend you to check out the rest of our step by step projects. LIKE us on Facebook and Google + to be the first that gets out latest projects.

2 comments

The measurements for this don’t work.

18.5 long top

14 inch long support attatched at both ends to a 4×4 {3.5 inches long} with a .75 inch lip on either side.

14 + 3.5 + 3.5 + .75 + .75 = 22.5 inches, 21 inches without the lip. How does a 18.5 inch top cover a 21 inch base?

That is true. I have updated the list with the correct lumber sizes.