This step by step diy project is about queen size bed plans. If you want to enhance your bedroom with a nice farmhouse bed and a queen size mattress, you should pay attention to the instructions described in this article. Invest in high quality materials and adjust the design of the bed to suit your needs and tastes. Assemble the bed in a professional manner, if you want a durable result.

It is essential to choose the right materials before starting the construction and the assembly of the bed frame. As you will see in the project, you need to choose durable lumber with a nice appearance, such as pine, cedar or redwood. Make sure the components are in a good visual condition and choose professional tools when adjusting their size. Take accurate measurements and join the components with glue and screws. See all my Premium Plans HERE.

Projects made from these plans

Queen Size Bed Plans

Cut & Shopping Lists

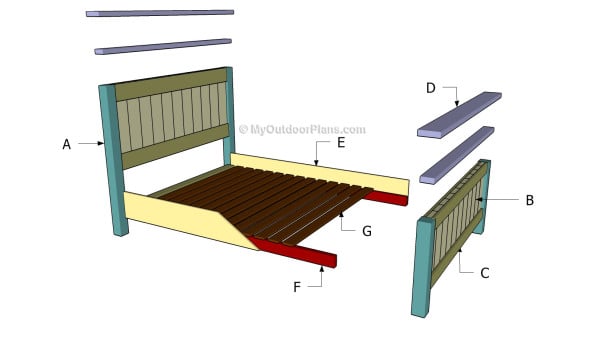

- A – 2 pieces of 4×4 lumber – 52″ long, 2 pieces – 26″ long LEGS

- B – 11 pieces of 1×6 lumber – 29″ long, 11 pieces – 20″ long SLATS

- C – 8 pieces of 1×6 lumber – 60 1/2″ long CLEATS

- D – 2 piece of 2×4 lumber – 67 1/2″ long, 2 pieces – 69 1/2″ long TRIMS

- E – 2 pieces of 1×10 lumber – 80 1/2″ long SIDES

- F – 2 piece of 2×4 lumber- 80 1/2″ long, 1 piece – 60 1/2″ long CLEATS

- G – 18 pieces of 1×4 lumber – 60 1/2″ long SUPPORT SLATS

- 2 pieces of 4×4 lumber – 8 ft

- 12 pieces of 1×6 lumber – 8 ft

- 7 pieces of 2×4 lumber – 8 ft

- 2 pieces of 1×10 lumber – 8 ft

- 9 pieces of 1×4 lumber – 12 ft

- 1 1/4″ screws

- 1 5/8″ screws

- 2 1/2″ screws

- filler, stain

- glue

Tools

![]() Hammer, Tape measure, Framing square

Hammer, Tape measure, Framing square

![]() Miter saw, Drill machinery, Screwdriver, Sander

Miter saw, Drill machinery, Screwdriver, Sander

Time

![]() One day

One day

Related

Building a queen size bed

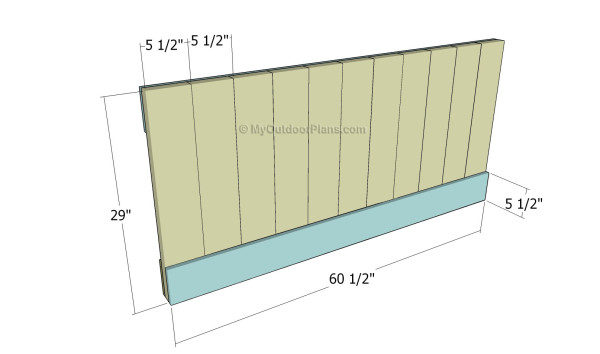

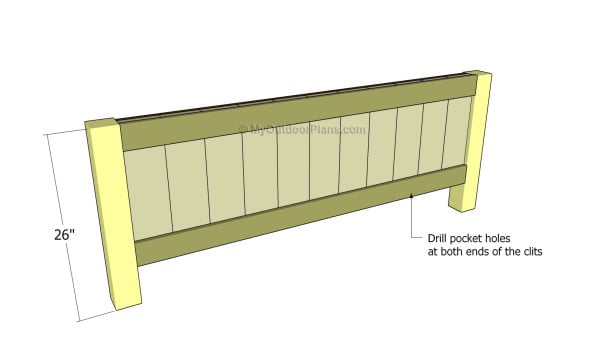

Building the headboard panel

The first step of the woodworking project is to build the panel for the headboard. As you can easily notice in the diagram, we recommend you to use 1×6 lumber for the vertical slats as well as for the cleats. In order to get a professional result, we recommend you to leave no gaps between the components.

Drill pilot holes through the cleats and insert galvanized screws. Add glue to the joints. Use 1 5/8″ screws.

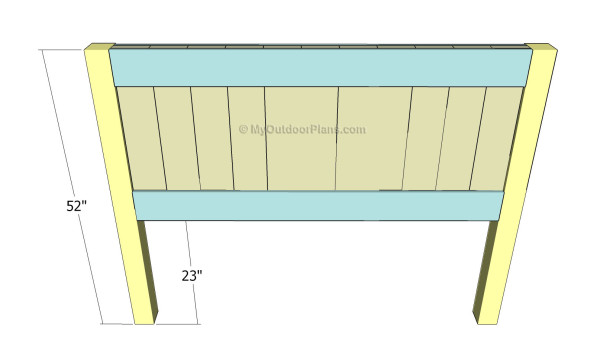

Building the heaboard

The next step of the woodworking project is to attach the 4×4 legs to the sides of the panel. In order to get the job done in a professional manner, we recommend you to drill pocket holes at both ends of the cleats and to insert 2 1/2″ screws into the legs.

Make sure the corners are right-angled and leave no gaps between the components. Add waterproof glue to the joints and remove the excess using a damp cloth.

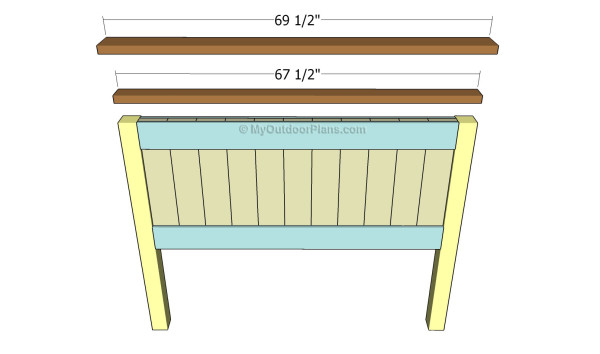

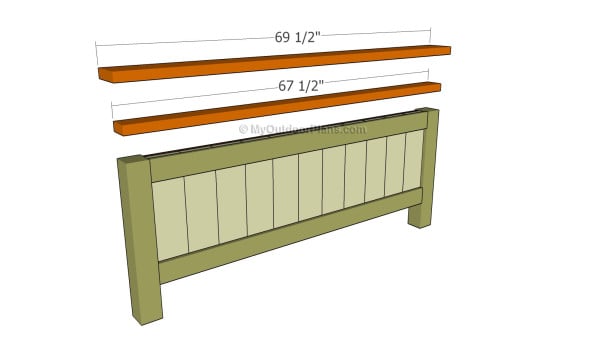

Fitting the top trims

In order to enhance the appearance of your farm queen size bed frame, we recommend you to attach the trims to the top of the headboard. As you can easily notice in the diagram, we recommend you to cut the trims out of 2×4 lumber and out of 2×6 lumber.

Drill pilot holes through the trims and secure them to the legs using 2 1/2″ screws. Add glue to the joints and make sure you center the components with great care.

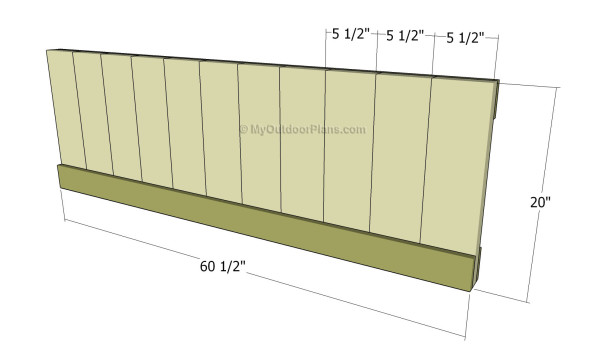

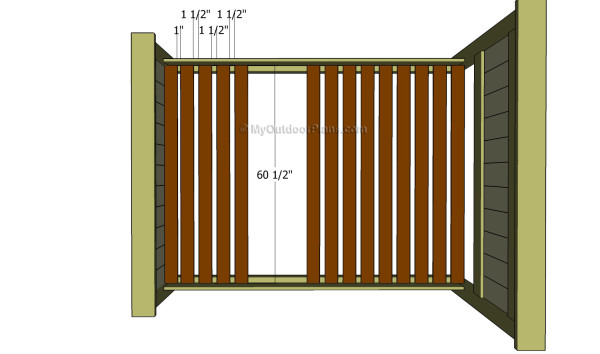

Building the footboard panel

Continue the project by assembling the footboard. In order to get a professional result, we recommend you to start with the panel. Build both the slats and the cleats out of 1×6 lumber.

Top Tip: Lay the 1×6 slats on a level surface and leave no gaps between them. Drill pilot holes holes through the wooden cleats and secure them to the vertical slats by using 1 1/4″ galvanized screws.

Building the footboard

Drill pilot holes at both ends of the cleats and insert 2 1/2″ screws into the 4×4 legs. Work with attention and with great care, if you want to get a professional result. The corners should be right-angled and the legs perfectly plumb.

Fitting the top trims to the footboard

Attach the 2×4 and 2×6 trims to the footboard, in the same manner described in the previous steps. Make sure the edges are flush and leave no gaps between the components. Smooth the exposed edges with sandpaper and make sure the top trim is perfectly centered into place.

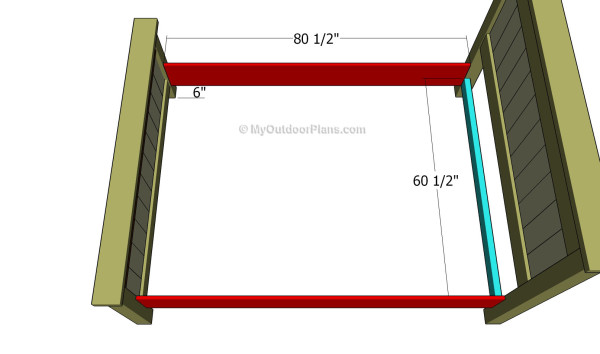

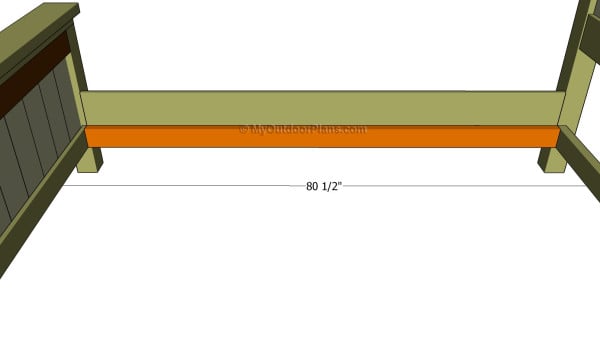

Building the frame of the queen bed

Assembling the frame of the bed frame is a straight-forward process. In order to get a professional result, you need to build the components out of 1×10 lumber. Drill pilot holes at both ends of the slats and secure them to the legs by using 1 1/4″ screws.

Make sure the corners are right-angled and place a spirit level on the side components, to make sure they are horizontal.

Fitting the side cleats

Attaching the 2×4 cleats to the interior sides of the queen size bed frame is a straight forward process. In order to get a professional result, we recommend you to invest in high quality materials and to make sure it is horizontal by using a spirit level.

Top Tip: Drill pilot holes through the cleats and insert 2″ galvanized screws into the side components. In addition, add glue to the joints in order to create rigid bonds.

Fitting the support slats

Fit the 1×4 support slats to the cleats and leave about 1 1/2″ between them. In order to get a professional result, we recommend you to secure the slats to the cleats by using 1 1/4″ screws.

Queen size bed frame plans

One of the last steps of the woodworking project is to take care of the finishing touches. Therefore, fill the pilot holes with wood putty and smooth the surface with 120-grit sandpaper.

Top Tip: In order to protect the lumber from water damage, we recommend you to cover the components with several coats of paint. Place the wooden bed in a proper location and move it whenever necessary.

This woodworking project was about queen size bed plans. If you want to see more outdoor plans, we recommend you to check out the rest of our step by step projects. LIKE us on Facebook to be the first that gets our latest plans. Send us pictures with your plans.

7 comments

Has anyone built this? Is there an easy to adapt it for use with box springs?

Does this need some sort of center support for the slats to avoid creaking?

No, because the weight is distributed evenly.

im trying to dl the qeen bed but not able to

Please read the FAQs: http://myoutdoorplans.com/faq/ Also, try using G Chrome and disable the ad blockers, if you use any.

what screws do i need for this project?

Added the screws to the list.