This step by step diy article is about dog ramp plans. If you want to learn more about how to build a dog ramp, we recommend you to pay attention to the instructions described in the article. Work with attention and invest in high-quality materials, such as pine, redwood or cedar. Select the slats with attention, making sure they are perfectly straight and in a very good condition.

Choose the most appropriate plans and design for the need of your dog and adjust the slope accordingly. If you want to get the job done in a professional manner, we recommend you to cover the dog ramp with carpet and to glue it into place. Work with attention and ask a skilled friend to assist you, as you need someone to hold the components into place while you insert the screws. See all my Premium Plans HERE.

Projects made from these plans

Cut & Shopping Lists

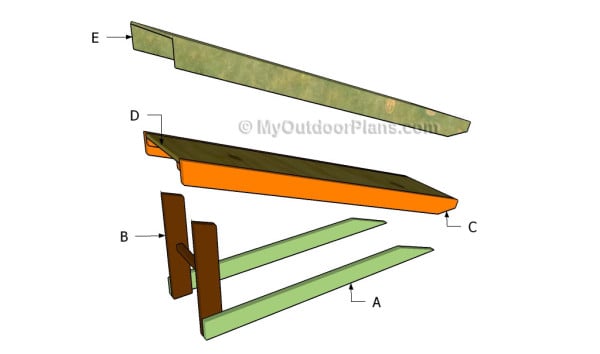

- A – 2 pieces of 2×4 lumber – 37 1/4″ long SUPPORTS

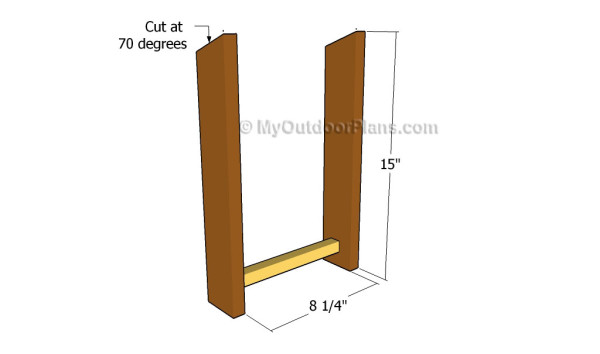

- B – 2 pieces of 2×4 lumber – 15″ long, 1 piece of 1×2 lumber – 8 1/4″ long SUPPORTS

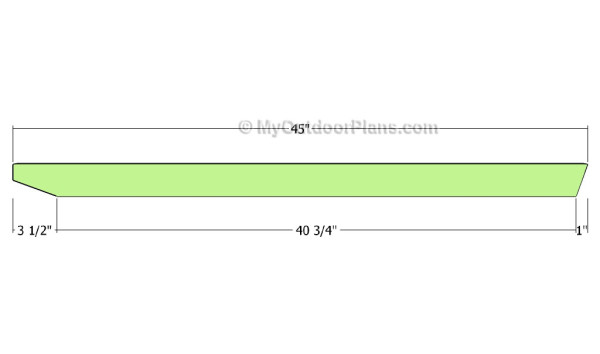

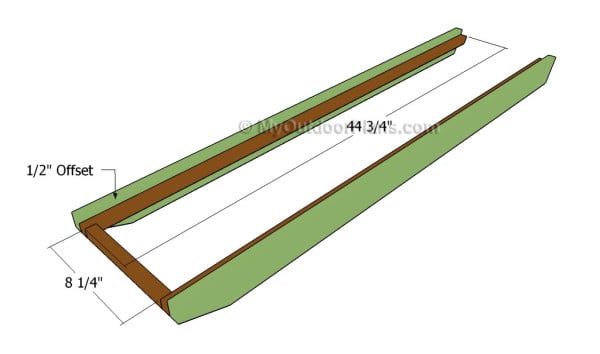

- C – 2 pieces of 2×4 – 45″ long, 2 pieces of 1×1 lumber – 44 3/4″ long RAILS

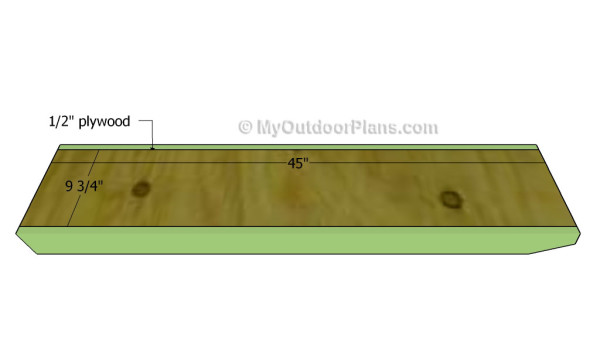

- D – 1 piece of 1/2″ plywood – 9 3/4″x45″ long RAMP

- E – carpet COVER

Tools

![]() Hammer, Tape measure, Framing square, Level

Hammer, Tape measure, Framing square, Level

![]() Miter saw, Drill machinery, Screwdriver, Sander

Miter saw, Drill machinery, Screwdriver, Sander

Time

Related

Dog Ramp Plans

Building a dog ramp

Top Tip: You should adjust the size and the angle of the dog ramp to suit the needs of your pet. Invest in quality materials, if yo want to get a professional result.

Building a dog ramp

Building the supports

The first step of the project is to build the supports for the dog ramp. As you can easily notice in the plans, we recommend you to cut the wooden components at the right size, as shown in the plans.

Use a good miter saw to make the angle cuts and assemble everything together with galvanized screws. Add waterproof glue to the joints in order to enhance the rigidity of the structure. Drill pilot holes through the side legs and insert 2 1/2″ screws into the support.

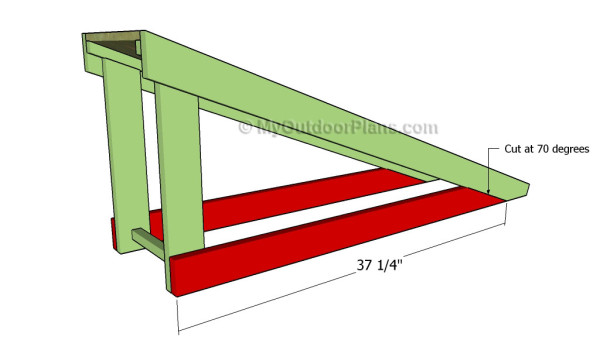

Building the sides rails

Next, we recommend you to build the frame of the dog rap. As you can notice in the plans, you need to build the side rails out of 2×4 lumber. Cut the ends at the right angles (20 degrees and 70 degrees) and smooth the cut edges with sandpaper.

Attaching the cleats

The next step of the woodworking project is to attach the 1×1 cleats on the interior faces of the dog ramp. Work with attention and secure the cleats to the rails with 1 5/8″ galvanized screws. Add waterproof glue to the joints, if you want to get a rigid structure. The cleats should be placed 1/2″ under the top edge of the side supports.

Attaching the ramp surface

Continue the woodworking project by assembling the dog ramp. As you can easily notice in the plans, we recommend you to cut a piece of 1/2″ plywood at the right size and fit it into place.

Drill several pilot holes along the edges of the plywood sheet and insert 1 5/8″ screws into the cleats. Add waterproof glue to enhance the rigidity of the dog ramp. Make sure there are no gaps between the components before inserting the screws.

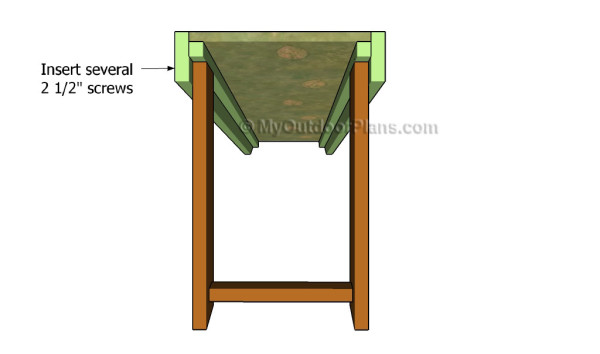

Attaching the supports into place

The next step of the process is to attach the supports to the dog ramp. Make sure you plumb the supports with a spirit level before locking the components together with galvanized screws.

Building the horizontal supports

If you really want to enhance the rigidity of the frame, we recommend you to attach 2×4 supports on both sides of the dog ramp. Cut one end at 20 degrees (70 degree cut), by using a miter saw, as to get a professional result.

Drill pocket holes at the end of the horizontal supports and insert 2 1/2″ screws into the frame of the dog ramp. Add waterproof glue to enhance the rigidity of the structure.

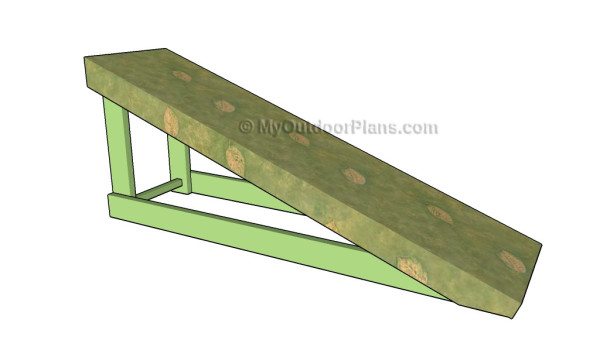

Dog ramp plans

One of the last steps of the woodworking project is to take care of the finishing touches. Therefore, fill the pilot holes with wood putty and smooth the surface with 120-grit sandpaper.

Top Tip: If you want to enhance the look of the woodworking project, we recommend you to cover the components with carpet. Place the wooden ramp in a proper location and move it whenever necessary.

This woodworking project was about dog ramp plans. If you want to see more outdoor plans, we recommend you to check out the rest of our step by step projects. LIKE us on Facebook and Google + to be the first that gets out latest projects.

8 comments

Hi, Can you explain how did you do the 70 degree cut? Thanks!

You use a miter saw. You set the angle at 20 degrees and make the cut. Your component will now have one end cut at 70 degrees.

You buy a “Speed square” , makes angle cuts easy. i have and Empire square in metric damn good bit of kit.

How do you get the PDF dog ramp plans aim a little slow and I have to keep looking at the picture lol

Please read the FAQs: http://myoutdoorplans.com/faq/

do you have a clickable link for the PDF? i am unable to locate it under FAQ?

There is a widget on the left side (not working on mobile)

Cut out 4 boards needed to assemble the base. The base can be the most complicated part, depending on how you build it. A simplified base can be made using only 4 boards, which provide a frame for the ramp and legs to attach to. Cut these out of pine boards about