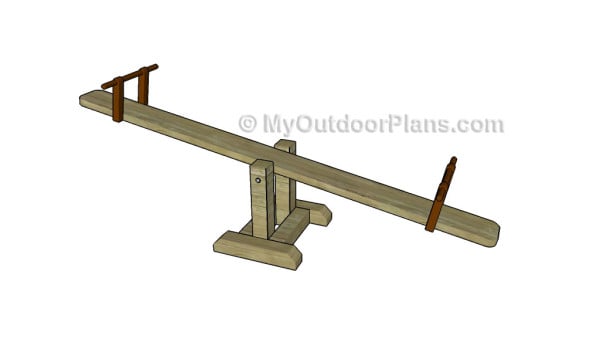

This step by step woodworking project is about how to build a simple seesaw plans. This article features detailed instructions for building a beautiful wooden seesaw for your kids. We have designed the plans to keep the expenditures under control and to involve the least amount of work possible. The simple seesaw can be built by anyone with basic tools and skills. This project should cost under 25-30 dollars in materials.

When buying the lumber, you should select the planks with great care, making sure they are straight and without any visible flaws (cracks, knots, twists, decay). Investing in cedar or other weather resistant lumber is a good idea, as it will pay off on the long run. Use a spirit level to plumb and align the components, before inserting the galvanized screws, otherwise the seesaw won’t have a symmetrical look. If you have all the materials and tools required for the project, you could get the job done in about a day. See all my Premium Plans HERE.

Projects made from these plans

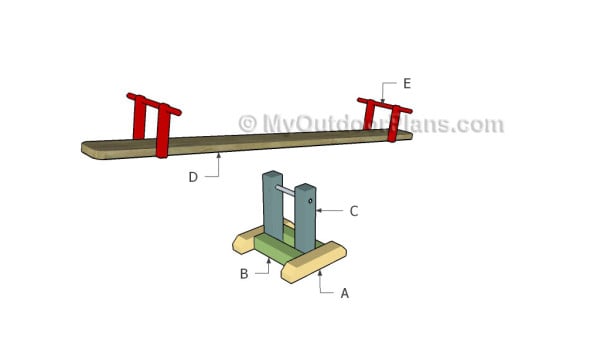

How to build a seesaw

Building a seesaw

Cut & Shopping Lists

- A – 2 pieces of 4×4 lumber – 24″ long BASE

- B – 2 pieces of 4×4 lumber – 15 1/2″ long SUPPORTS

- C – 2 pieces of 4×4 lumber – 20″ long VERTICAL SUPPORTS

- D – 1 piece of 2×8 lumber – 96″ long SEAT

- E – 2 pieces of 2×2 lumber – 10″ long, 1 piece of 1/2″ dowel – 18 1/2″ long 2xHANDLE

- 2 pieces of 4×4 lumber – 8 ft

- 1 piece of 2×8 lumber – 8 ft

- 1 piece of 2×2 lumber – 8 ft

- 1 piece of 1/2″ dowel – 4 ft

- pipe, strap clamp

- 1 1/4″ screws

- 1 5/8″ screws

- 2 1/2″ screws

- filler, stain

- glue

Tools

![]() Hammer, Tape measure, Framing square, Level

Hammer, Tape measure, Framing square, Level

![]() Miter saw, Drill machinery, Screwdriver, Sander

Miter saw, Drill machinery, Screwdriver, Sander

Time

![]() One day

One day

Free simple seesaw plans

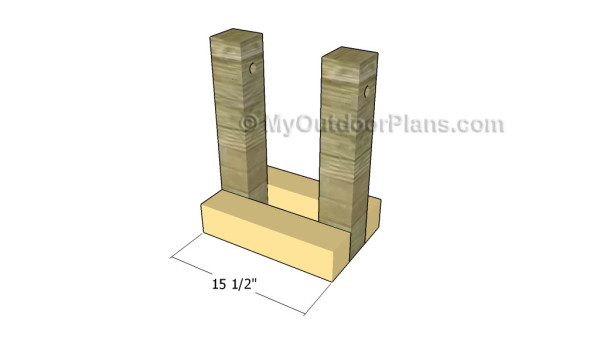

Building the vertical posts

The first step of the project is to build the vertical posts for the seesaw. Cut the supports out of 4×4 lumber and drill 1″ pilot holes though them, as shown in the diagram. You can adjust the size of the vertical supports to suit your needs.

Building the base

Next, you need to build the base for the seesaw. Cut the components out of 4×4 lumber and secure them to the vertical supports using 5″ screws. Make sure the vertical posts are plumb before inserting the screws. Add waterproof glue to the joints to get a professional result.

Attaching the base

Continue the project by fitting the rest of the components to the base. Use 4×4 lumber for the components and secure them to the base using 5″ screws. Add glue to the joints and make sure the corners are square. It is essential to create rigid joints.

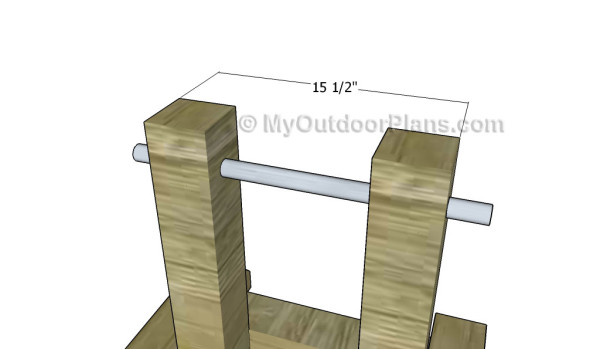

Fitting the pipe

Next, fit the pipe to the vertical supports, as shown in the diagram. Alternatively, you could use threaded rod and place washers and nuts on the exterior faces.

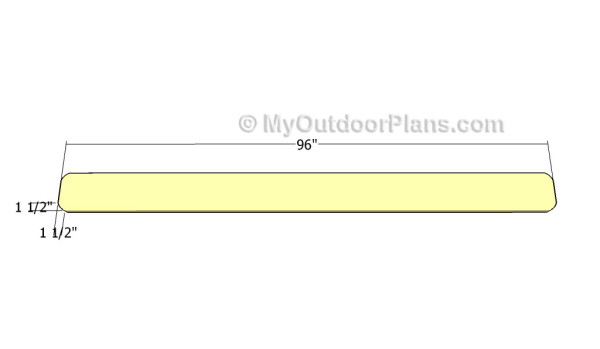

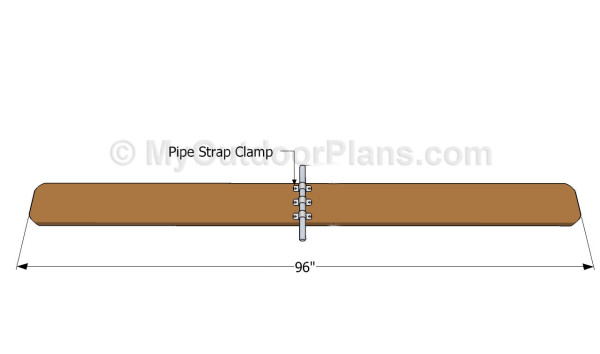

Building the seat beam

Build the seat for the seesaw out of 2×8 lumber. Round the corners of the plank, as described in the diagram. Smooth the edges with fine-grit sandpaper.

Attaching the pipe

Next, you need to attach the pipe strap clamps to the bottom of the beat beam. Mark the center of the plank and attach the clamps using the information from the diagram. Make sure the pipe can rotate easily, otherwise the seesaw won’t pivot.

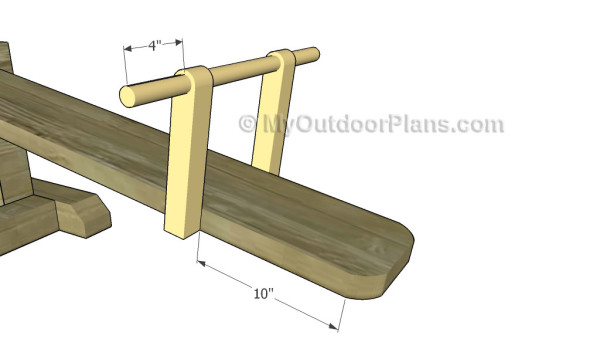

Building the handles

Building the handles for the seesaw is fairly simple, but you need to use the right materials. Use 1×2 or 2×2 lumber for the vertical supports and 1/2″ dowels for the actual handle. Drill pilot holes through the supports and insert the dowel. Secure the handle to the supports by using glue and screws. Smooth the edges with fine-grit sandpaper.

Attaching the handles

Secure the supports to the sides of the seat beam using 2 1/2″ screws and waterproof glue. Make sure the joints are rigid before testing the seesaw. Round the top of the supports and smooth the edges with 120 grit sandpaper.

Free seesaw plans

One of the last steps of the woodworking project is to take care of the finishing touches. Therefore, fill the pilot holes with wood putty and smooth the surface with 120-grit sandpaper.

Top Tip: If you want to enhance the look of the project and to protect the wooden seesaw with bench from decay, we recommend you to cover the components with paint or stain.

This woodworking project was about how to build a simple seesaw plans. If you want to see more outdoor plans, we recommend you to check out the rest of our step by step projects. LIKE us on Facebook and Google + to be the first that gets out latest projects and to hep us keep adding free woodworking plans for you.

2 comments

An ideal ‘easy’ project- despite extortionate cost of timber this is an economical accessory for young children’s garden.The plans are straightforward and follow a linear progression.

What would you estimate to be the weight limit for this?