This step by step diy woodworking project is about shed ramp plans. The project features instructions for building a simple 3′ wide shed ramp. The shed ramp is sturdy and simple to build in the same time. Work with attention and make adjustments to the design and overall dimensions if you want to get the job done in a professional manner. Don’t forget to take a look over the related projects for more inspiration and ideas.

When buying the lumber, you should select the planks with great care, making sure they are straight and without any visible flaws (cracks, knots, twists, decay). Investing in cedar or other weather resistant lumber is a good idea, as it will pay off on the long run. Use a spirit level to plumb and align the components, before inserting the galvanized screws, otherwise the project won’t have a symmetrical look. If you have all the materials and tools required for the project, you could get the job done in about a day. See all my Premium Plans HERE.

Projects made from these plans

Shed Ramp Plans

Building a shed ramp

Cut & Shopping Lists

- A – 1 piece of 2×4 lumber – 36″ long LEDGER

- B – 4 pieces of 2×4 lumber – 36 1/2″ long JOISTS

- C – 1 piece of 1×4 lumber – 36″ long SUPPORT

- D – 1 piece of 3/4″ plywood – 36″x36 1/2″ long RAMP

- 2 pieces of 2×4 lumber – 10 ft

- 1 piece of 3/4″ plywood – 4’x4′

- 1 piece of 1×4 lumber – 6 ft

- 1 1/4″ screws

- 1 5/8″ screws

- 2 1/2″ screws

- filler, stain

- glue

Tools

![]() Hammer, Tape measure, Framing square, Level

Hammer, Tape measure, Framing square, Level

![]() Miter saw, Drill machinery, Screwdriver, Sander

Miter saw, Drill machinery, Screwdriver, Sander

Time

![]() One day

One day

How to build a shed ramp

Fitting the ledger

The first step of the project is to attach the 2×4 ledger to the shed. Drill pilot holes through the ledger and insert 2 1/2″ screws into the joists. Use a spirit level to make sure the ledger is perfectly horizontal.

Laying the concrete slab

If you want to build a heavy duty shed ramp, you need to pour a concrete slab (at least 2″ thick) or to lay 12″x12″ concrete pavers to support the joists. However, you need to remove the vegetation first and dig enough into the ground so that the slab will be flush with the surface. In this manner, you will make sure the surface is perfectly level and rigid enough to support weight over the long run. Placing the joists directly on the ground is not the best idea, as the moisture will damage the wood.

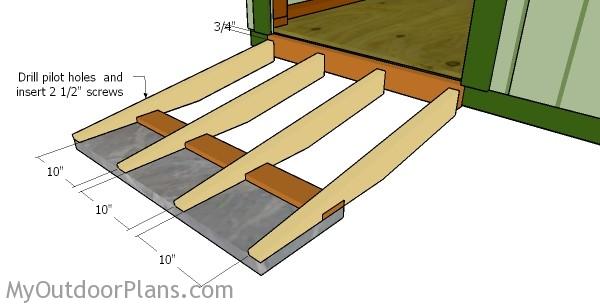

Attach a piece of 1×4 lumber to the slab, as shown in the diagram. Drill pilot holes and secure it into place with concrete screws.

Building the joists

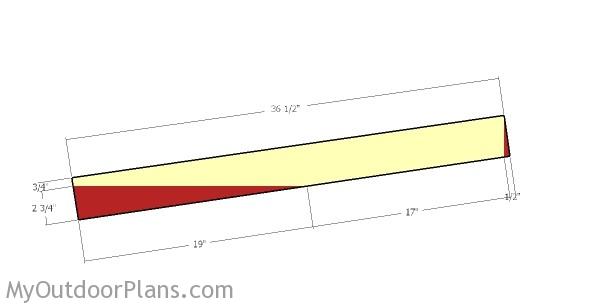

Build the joists for the shed ramp from 2×4 lumber. Mark the cut lines to the slats and get the job done with a circular saw. Smooth the edges with sandpaper.

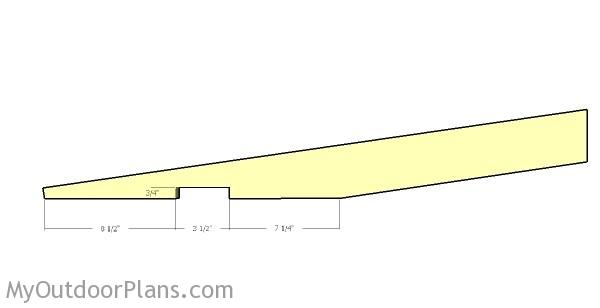

Making the notch in the joists

Make notches to the joists, as shown in the diagram. In order to create proper notches, you need to make several parallel cuts to the joists and remove the excess with a chisel. Clean the recess with sandpaper.

Fitting the joists

Fit the joists to the shed, as shown in the diagram. Use metal hardware to secure the joists to the ledger, making sure you leave 3/4″ from the top of the ledger to the joists. Drill pilot holes through the joists and insert 2 1/2″ screws into the support slat at the opposite end. Make sure you place the joists equally-spaced for a professional result.

Attaching the ramp sheet

Last but not least, you need to attach the plywood ramp to the joists and secure it into place with 1 1/4″ screws. Alternatively, you can use 1×4 or 1×6 slats if you find it more convenient.

Shed Ramp Plans

Fill the holes and dents with wood putty and let it dry out for several hours. Use 120-200 grit sandpaper to smooth the surface.

Top Tip: If you want to enhance the look of the project and to protect the wood storage shed ramp, we recommend you to cover the components with paint or stain.

This woodworking project was about shed ramp plans. If you want to see more outdoor plans, we recommend you to check out the rest of our step by step projects. LIKE us on Facebook and Google + to be the first that gets out latest projects and to hep us keep adding free woodworking plans for you.

EXPLORE MORE IDEAS FOR:

|

|

|

|

1 comment

thanks