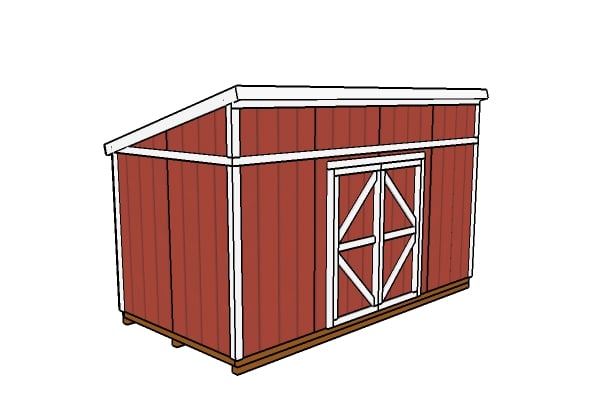

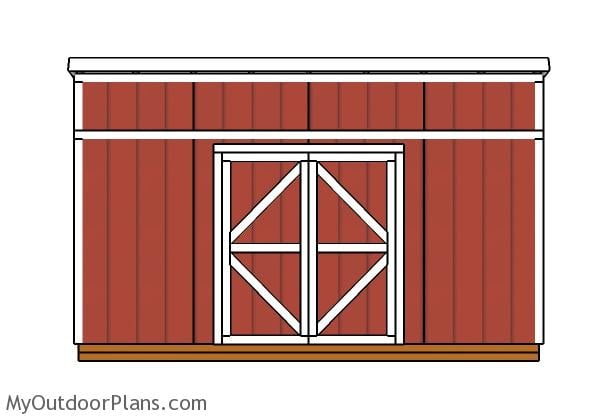

This step by step diy project is about 8×16 shed plans. I have designed this shed with a lean to roof and with a generous front double door, so you can shelter a lot of items inside. Take a look over the rest of my woodworking plans, if you want to get more building inspiration. Remember that you need to select the site for the shed with attention and that you have to comply with a few legal regulations.

When buying the lumber, you should select the planks with great care, making sure they are straight and without any visible flaws (cracks, knots, twists, decay). Investing in cedar or other weather resistant lumber is a good idea, as it will pay off on the long run. Use a spirit level to plumb and align the components, before inserting the galvanized screws, otherwise the project won’t have a symmetrical look. If you have all the materials and tools required for the project, you could get the job done in about a day.

Building a 8×16 lean to shed

Building-a-8×16-lean-to-shed

Cut & Shopping Lists

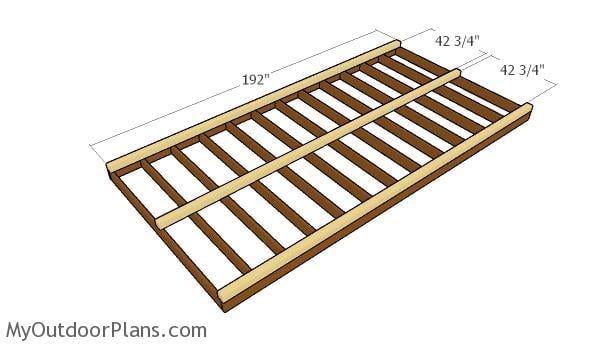

- A – 3 pieces of 4×4 lumber – 16′ long SKIDS

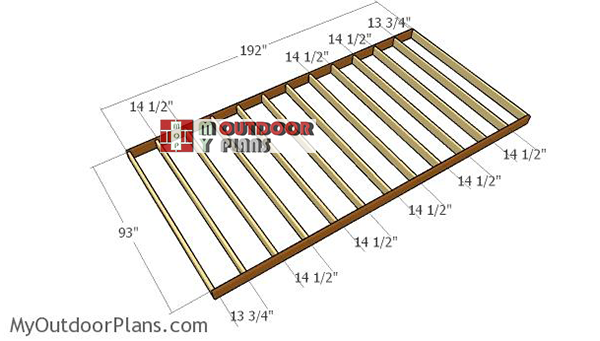

- B – 2 pieces of 2×6 lumber – 192″ long, 13 pieces – 93″ long FLOOR FRAME

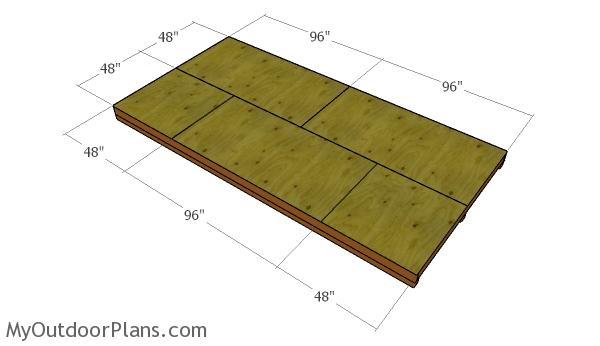

- C – 3 pieces of 3/4″ plywood – 48″x96″ long, 2 pieces – 48″x48″ long FLOOR

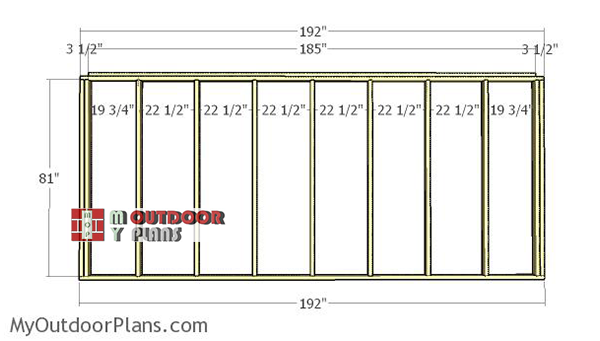

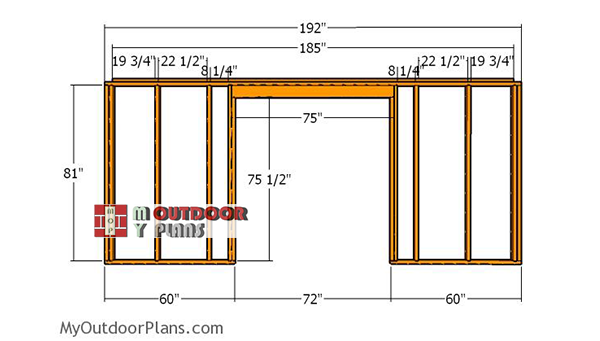

- D – 1 pieces of 2×4 lumber – 192″ long, 1 piece – 185″ long, 2 pieces – 60″ long, 10 pieces – 81″ long, 2 pieces – 75 1/2″ long, 2 pieces of 2×6 lumber – 75″ long FRONT WALL

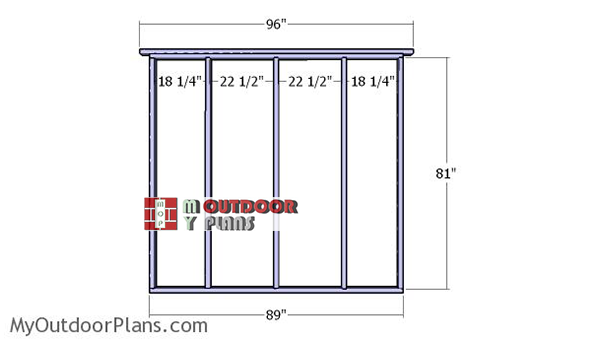

- E – 2 piece of 2×4 lumber – 89″ long, 1 piece – 96″ long, 5 pieces of 1×4 lumber – 81″ long 2xSIDE WALL

- F – 2 pieces of 2×4 lumber – 192″ long, 1 piece – 185″ long, 11 pieces – 81″ long BACK WALL

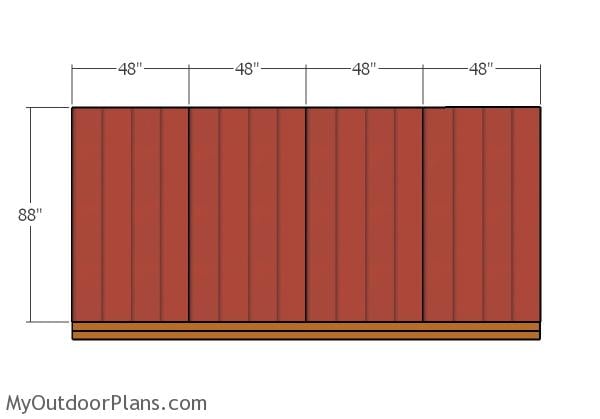

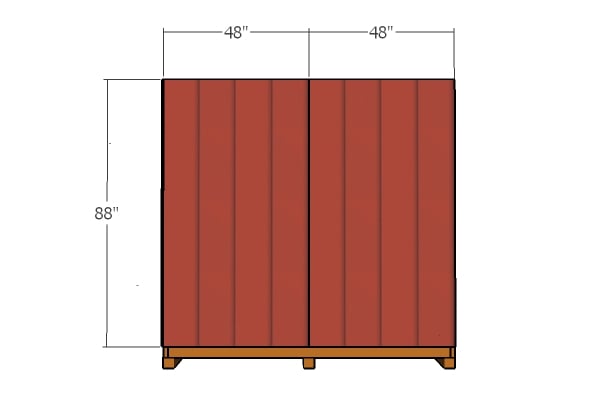

- G – 12 pieces of T1-11 5/8″ siding – 48″x88″ long, 4 pieces – 24″x48″ long SIDING

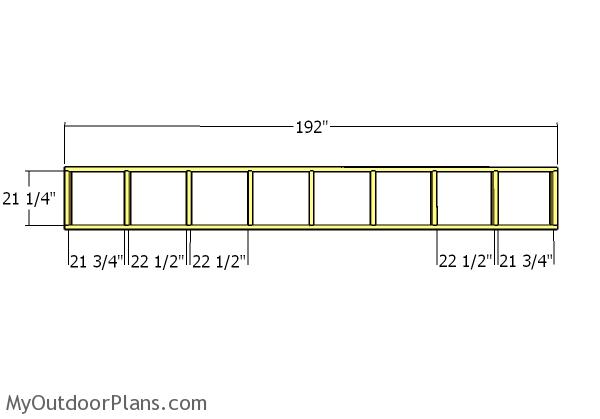

- H – 2 pieces of 2×4 lumber – 192″ long, 9 pieces – 21 1/4″ long TOP FRAME

- 3 pieces of 4×4 lumber – 16′

- 4 pieces of 2×6 lumber – 16′

- 13 pieces of 2×6 lumber – 8′

- 4 pieces of 3/4″ plywood – 48″x96″

- 8 pieces of 2×4 lumber – 16′

- 37 pieces of 2×4 lumber – 8′

- 2 pieces of 2×6 lumber – 8′

- 13 pieces of T1-11 5/8″ siding – 4’x8′

- 2 1/2″ screws, 3 1/2″ screws, 1 5/8″ screws

- 4d nails, 16d nails

- wood filler , wood glue, stain/paint

Tools

![]() Hammer, Tape measure, Framing square, Level

Hammer, Tape measure, Framing square, Level

![]() Miter saw, Drill machinery, Screwdriver, Sander

Miter saw, Drill machinery, Screwdriver, Sander

Time

Related

- PART 1: 8×16 Shed Plans

- PART 2: 8×16 Shed Roof Plans

- PART 3: Shed Doors Plans

8×16 Shed Plans

Assembling-the-floor-frame-shed

The first step of the project is to build the floor for the 8×16 shed. Cut the joists from 2×6 lumber and assemble the floor frame with 3 1/2″ screws. Make sure the corners are square and then fit the joists, every 16″ on center.

Fitting-the-skids

Fit the 4×4 skids to the bottom of the frame, using metal connectors or by inserting screws, after drilling pilot holes.

Fitting-the-plywood-sheets

Attach the 3/4″ plywood sheets to the floor of the shed. Make sure you leave no gaps between the components for a neat result. Insert 1 5/8″ screws through the plywood sheets into the joists, every 8″.

Building-the-side-wall-frame

Assemble the wall frames for the shed from 2×4 lumber. Drill pilot holes through the top and bottom plates and insert 3 1/2″ screws into the studs. Place the studs every 24″ or 16″ on center.

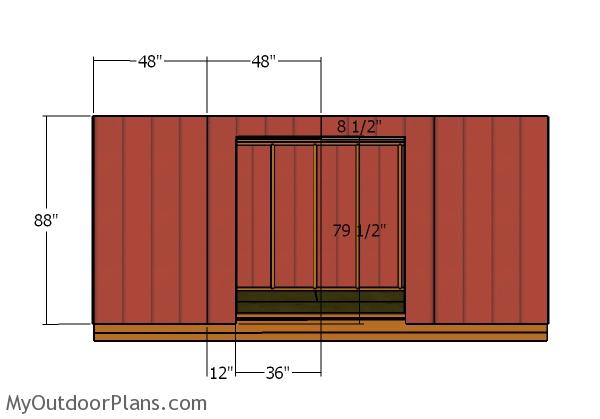

Building-the-front-wall

Assemble the front wall, making sure you leave enough space for the door opening. You can adjust the size of the door to suit your needs. Make sure you use 2×6 lumber for the double header and 2×4 lumber for the king studs.

Building-the-back-wall-frame

Assemble the side walls using the same instructions described above, but make sure you use the information from the diagram.

Assembling-the-8×16-shed-frame

Fit the wall frames to the floor of the shed. Align the edges with attention and use a spirit level to make sure they are plumb. Drill pilot holes through the bottom plates and insert 3 1/2″ screws into the floor. In addition, lock the adjacent walls together using screws, after making sure the corners are square.

Fitting-the-siding-panels-to-the-back-of-the-shed

Attach T1-11 siding to the back wall. Align the edges with attention and then secure the sheets into place with 4d nails, every 8″ along the framing.

Fitting-the-siding-panels-to-back

Attach the siding panels to the sides of the shed, as well. Align the edges with attention and then insert 4d nails to lock the sheets into place tightly.

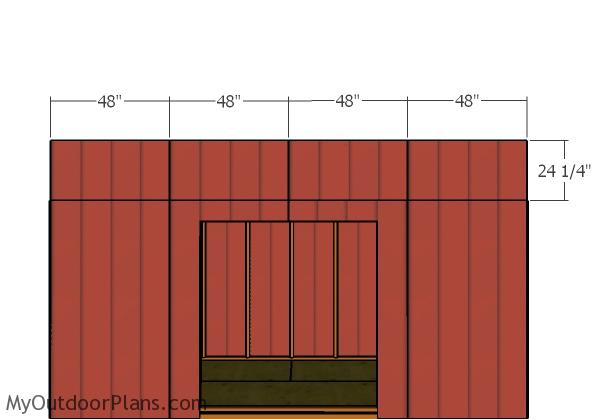

Fitting-the-siding-panels-to-the-front-of-the-shed

Fit the siding panels to the front of the lean to shed, as well. Cut out the sheets that go around the door opening, for a professional result.

Building-the-front-top-wall

Build the top frame for the front of the shed, using the instructions from the above diagram. Drill pilot holes through the plates and insert 3 1/2″ screws into the studs. Make sure the corners are square and align the edges flush.

Front-top-wall

Fit the top wall to the front of the shed, as shown in the plans. Align the edges flush and make sure the corners are square. Drill pilot holes through the bottom plates and insert 2 1/2″ screws into the shed front wall.

Fitting-the-top-front-panels

Attach the siding panels to the top of the shed, as well.

8×16-shed-plans

Make sure you check out PART 2 and PART 3 of the lean to shed project, so you learn how to build the roof and the double doors for the shed. In addition, I will show you how to install the trims to the shed, so you enhance its look.

8×16-shed-plans-front-view

This shed is roomy enough for lots of items, so if you are looking for a cheap and straight-forward way of keeping your things protected from the elements, this shed is one good choice. Don’t forget to take a look over PART 2 and PART 3 to learn how to build the roof for the shed, as well as how to frame the double front doors.

This woodworking project was about 8×16 shed plans free. If you want to see more outdoor plans, check out the rest of our step by step projects and follow the instructions to obtain a professional result.

18 comments

How do i get printable drawings for this project?

Please read the FAQs: http://myoutdoorplans.com/faq/

What are the 6x6x12s for? Never saw them in the instructions!

They are for the skids, under the floor frame.

If the joists are 93″ and the side lengths are made from 2 x 6…then total width is 97″ . How does this work with 96″ 3/4 OSB flooring?

2×6 lumber is actually 1 1/2″ x 5 1/2″ See this table for further reference: http://myoutdoorplans.com/imperial-to-metric-conversion/

Thanks a lot for the reply…makes it clear now. Many thanks. Billy

I have a question about the 6x6x12

Is there another option for this? This size is not available in my area, so was wondering what else I could do. Would 6x6x8 or 6x6x10 work?

Thank you.

You don’t need the 6x6s for this project. It was a typing error. I have updated the materials list.

Hi

Is there a good reason not to make the walls 8 inches taller? Then I could use full sheets of wall boards, and gain extra height inside and in the door.

Thanks 🙂

Yes, local codes. Some don’t allow you to make the walls 8′ high.

I used these plans to make an 8 x 16’ lean shed, with modifications for two windows and a French door. I found the plans extremely useful and used the material list for lumber yard runs. I found it helpful to purchase materials for one aspect at a time, using my small Ford Ranger to pick up the materials. For example, I first bought the foundation/flooring materials and constructed them. I then bought the material for the walls including the siding; then the roof supports and sheeting; and lastly the shingles and flashing. The shed is in our back yard which is not accessible by vehicle, so I had to carry everything to the back from the driveway. Using just in time delivery helped me operate in a confined area. Thanks so much for these plans!

Does this require the skids, I was thinking of laying it out on a compressed gravel or rock bed without the skids.

The skids are needed, unless you attach the walls to a concrete slab

Hello – curious why the plywood on the floor was laid out that way versus 4 whole pieces next to each other with T&G? Would this be a stronger design with this type of joint stagger versus just three joints 8′ long.

Because that’s the standard to add rigidity to the floor frame.

Do have estimated costs for your plans? We are very interested in your 8×16 Lead to Shed plan.

Thank you for your attention.

Yes, sure. Estimated costs are 1500-2000 usd.