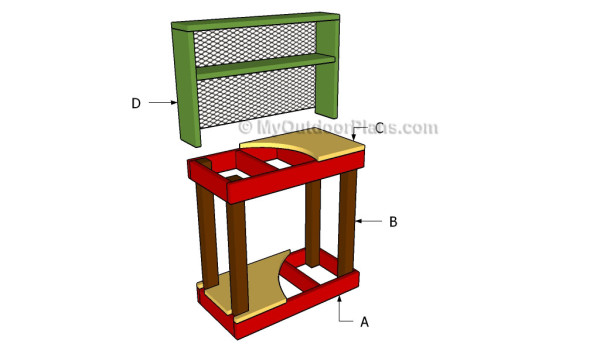

This step by step article is about reloading bench plans. If you want to build a sturdy reloading bench for your garage, you should pay attention to the instructions described in the article. The project features a reloading bench with storage shelves, so that you can organize all your tools and materials in a professional manner. Make the necessary adjustments to suit your needs and budget.

In order to build a sturdy wood bench, we recommend you to buy the appropriate lumber for your needs. Therefore, 2×4 pressure-treated lumber is a good choice, provided the beams are in good condition. On the other hand, you could build the bottom shelf and the top of the bench from thick plywood or OSB, as the sheets are easy to cut and support a significant weight. Nevertheless, there are many variations on the theme, as you could even install a laminate counter-top or attach several electrical outlets. See all my Premium Plans HERE.

Projects made from these plans

Reloading bench plans

Building a reloading bench

Cut & Shopping Lists

- A – 4 pieces of 2×6 lumber – 21” long, 2 pieces -47 ” long 2xFRAME

- B – 4 pieces of 4×4 lumber 48” long LEGS

- C – 4 pieces of 3/4″ plywood – 47″ x 24″ long 2xTABLETOPS

- D – 2 pieces of 2×10 lumber – 30 1/2″ long, 1 piece – 47″ long, 1 piece – 50″ long SHELVES

- 4 pieces of 2×6 lumber – 8 ft

- 2 pieces of 4×4 lumber – 8 ft

- 1 piece of 3/4″ plywood – 4’x8′

- 2 pieces of 2×10 lumber – 10 ft

- 2 1/2″ screws

- 1 5/8″ screws

- 1 1/4″ screws

- wood filler

- wood glue

- stain/paint

Tools

![]() Hammer, Tape measure, Framing square

Hammer, Tape measure, Framing square

![]() Miter saw, Drill machinery, Screwdriver, Sander

Miter saw, Drill machinery, Screwdriver, Sander

Time

Building a reloading bench

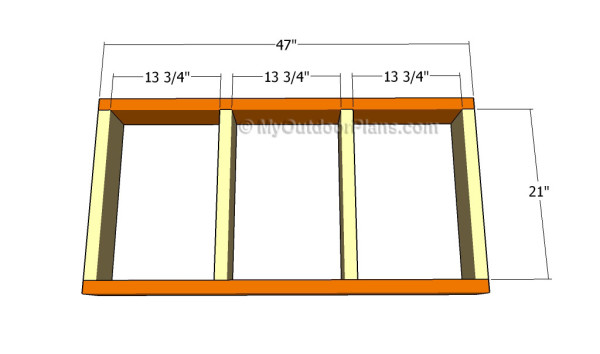

Building the frames

The first step of the woodworking project is to build the frames for the reloading bench. As you can easily notice in the diagram, you should build the components out of 2×6 lumber. Cut the components at the right size and smooth the cut edges before drilling pilot holes.

Afterwards, drill pilot holes through the side components and insert 2 1/2″ screws into the perpendicular components. Make sure the corners are square and add glue to the joints.

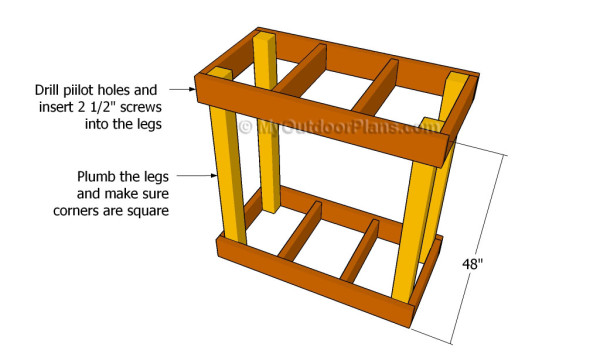

Assembling the frame of the reloading bench

The next step of the woodworking project is to assemble the frame of the reloading bench. Therefore, cut the legs for the bench out of 4×4 lumber. Plumb the legs with a spirit level and drill pilot holes through the frames.

Make sure the frames are horizontal and check if the corners are square. Insert 2 1/2″ screws through the frames inside the legs and add glue to the joints. Leave no gaps between the components.

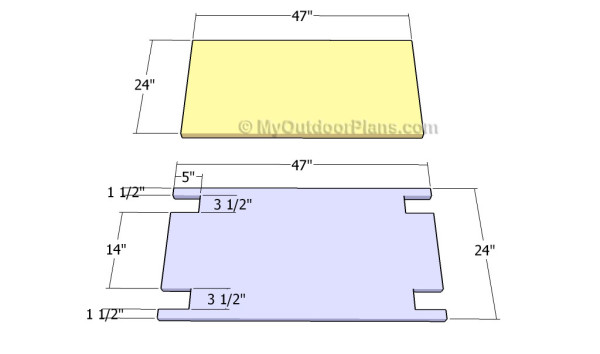

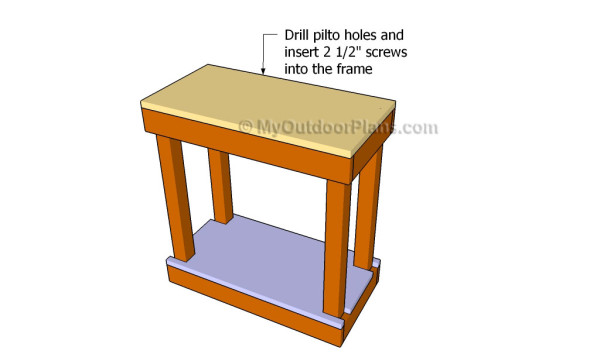

Building the tabletops

Afterwards, build the shelf and the tabletop for the reloading bench out of 1 1/2″ plywood. As you can easily notice in the diagram, you need to make several notches in the bottom shelf, in order to fit around the legs.

Top Tip: Take accurate measurements and smooth the cut edges before continuing the woodworking project. Make sure the corners are square before making the cuts.

Fitting the tabletops

Lay the plywood components over the structure and make sure the edges are flush. Drill pilot holes along the edges of the plywood pieces and insert 2 1/2″ screws into the joints.

Add waterproof glue to the joints and leave no gaps between the components. Smooth the exterior edges and remove the residues with a cleaner. Fit the bottom shelf in the same manner described above.

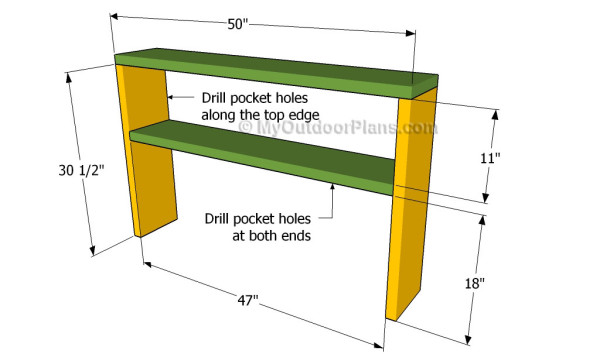

Assembling the back shelves

One of the last steps of the woodworking project is to build the back shelves for the reloading bench. As you can easily notice in the diagram, we recommend you to use 2×10 lumber for the components.

Drill pocket holes along the top edges of the side components and secure them to the top components using 2 1/2′ screws. Drill pocket holes along the middle shelf and secure it to the structure using 2 1/2″ screws.

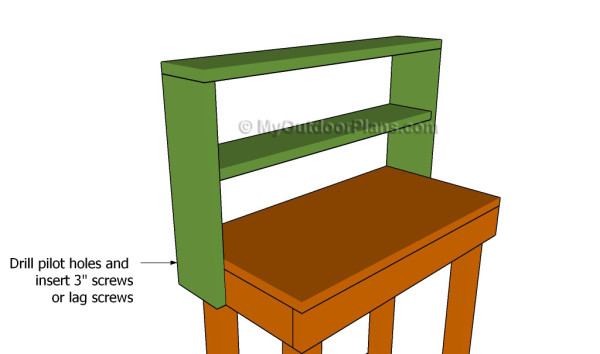

Attaching the back shelves

After assembling the structure out of 2×10 lumber, we recommend you to make sure the corners are square and there are no leave between the components. Add glue to enhance the bond of the joints.

Drill pilot holes through the sides of the structure and insert 2 1/2″ galvanized screws or lag bolts. Plumb the sides with a spirit level and make sure the top is horizontal.

Reloading bench plans

Don’t forget that you could adjust the size of the reloading bench according to your needs. If you follow our step by step instructions, the bench will be rigid enough to support your own weight.

Top Tip: Apply several coats of wood stain in order to protect the lumber from wood decay or water damage. Fill the head of the screws with wood putty, before sanding the surface with 120-grit sandpaper.

This woodworking project is about reloading bench plans. If you want to see more outdoor plans, check out the rest of our step by step projects and follow the instructions to obtain a professional result.