This step by step article is about portable reloading bench plans. If you need a small reloading bench for your workshop that you could carry it with you, we recommend you to take a close look over the plans described in the article. There are many designs you could choose from, so make sure you take a look over the alternatives before starting the actual construction of the bench.

In order to build a sturdy wood bench, we recommend you to buy the appropriate lumber for your needs. Align the wooden components at both hand before driving in the screws. Don’t forget to pre-drill holes in the components, as to prevent the wood from splitting. Moreover, don’t forget to countersink the head of the screws, before inserting the wooden screws. Last but not least, apply a good wood filler in the holes, let it dry out properly and sand the surface thoroughly with 120-grit sandpaper, before applying the final coats of stain. See all my Premium Plans HERE.

Projects made from these plans

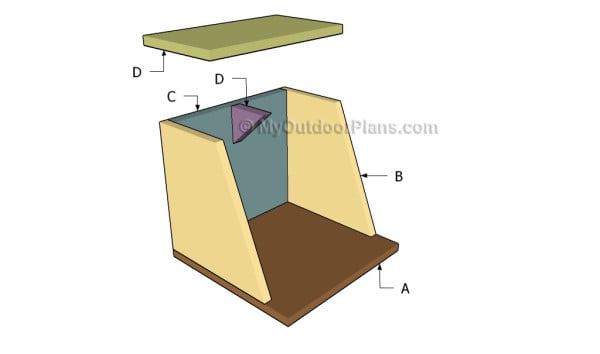

Portable Reloading Bench Plans

Building a portable reloading bench

Cut & Shopping Lists

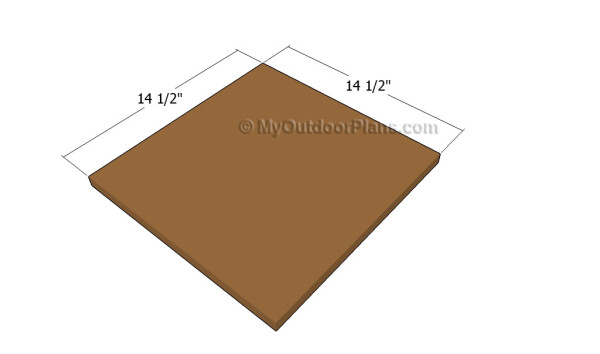

- A – 1 pieces of 3/4″ plywood – 14 1/2” x 14 1/2″ long BOTTOM

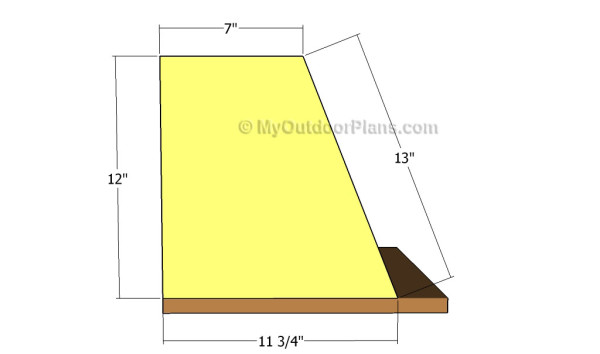

- B – 2 pieces of 3/4′ plywood – 11 3/4” x 12″ long SIDES

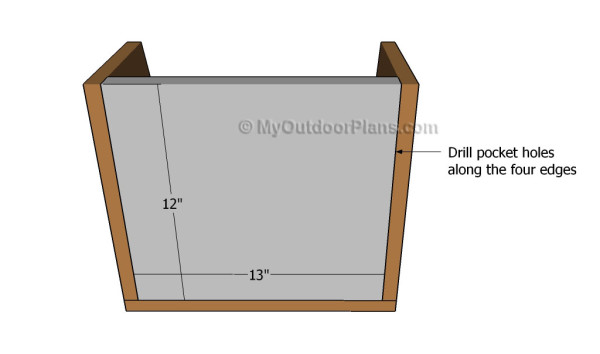

- C – 1 piece of 3/4″ plywood – 12″ x 13″ long BACK

- D – 1 pieces of 2×4 lumber – 3 1/2” long SUPPORT

- E – 1 piece of 3/4″ plywood – 8″ x 14 1/2″ long TOP

- 1 pieces of 2×4 lumber – 1 ft

- 1 piece of 3/4″ plywood – 4’x8′

- 2 1/2″ screws

- 1 5/8″ screws

- 1 1/4″ screws

- wood filler

- wood glue

- stain/paint

Tools

![]() Hammer, Tape measure, Framing square

Hammer, Tape measure, Framing square

![]() Miter saw, Drill machinery, Screwdriver, Sander

Miter saw, Drill machinery, Screwdriver, Sander

Time

Building a portable reloading bench

Building the base of the reloading bench

The first step of the woodworking project is to build the base for the reloading bench. As you can easily notice in the diagram, we recommend you to mark the cut lines on the 3/4″ plywood and to get the job done with a circular saw. Make sure the corners are square and smooth the cut edges with sandpaper.

Building the sides of the bench

The next step of the woodworking project is to build the sides of the portable reloading bench. As you can notice in the diagram, we recommend you to mark the cut lines on the 3/4″ plywood pieces and to get the job done with a circular saw.

Drill pocket holes along the bottom edges of the side components and align them with attention. Add glue to the joints and insert 1 1/4″ screws to secure the components properly. Make sure the corners are square and leave no gaps between the components.

Fitting the back to the structure

Afterwards, we recommend you to build the back of the reloading bench out of 3/4″ plywood. Drill pocket holes along the edges of the component and fit it into place, as described in the diagram. Make sure you don’t crack the edges.

Top Tip: Leave no gaps between the components and insert 1 1/4″ screws, in order to create rigid joints. Add waterproof glue to the joints, in order to enhance the rigidity of the structure.

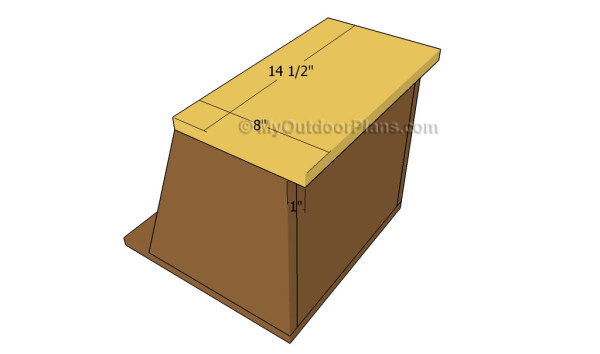

Fitting the top

One of the last steps of the project is to attach the top of the portable reloading bench. In order to get a professional result, we recommend you to adjust the size of the top components according to your needs.

If you want to use it as a shelf, make it slightly wider. Align it with great care and secure it into place by insert 1 1/4″ screws through the sides into the top component. Add glue to the joints and remove the excess with a damp cloth.

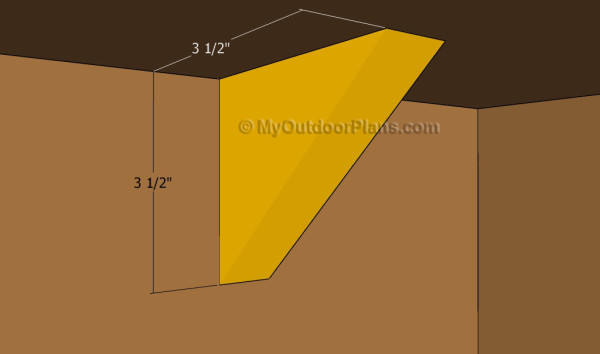

Fitting the top support

In order to enhance the rigidity of the structure, we recommend you to attach a 2×4 support to the top of the structure, as described in the diagram. Drill pocket holes along the edges, center it to the structure and lock it into place using 1 1/4″ screws. Add glue to the joints and remove the excess using waterproof glue.

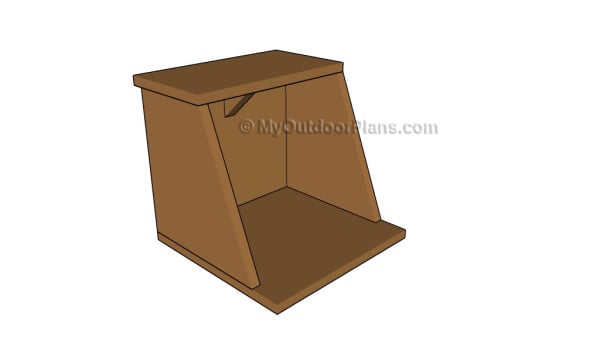

Portable reloading bench plans

Don’t forget that you could adjust the size of the diy workbench according to your needs. If you follow our step by step instructions, the bench will be rigid enough to support your own weight.

Top Tip: Apply several coats of wood stain in order to protect the lumber from wood decay or water damage. Fill the head of the screws with wood putty, before sanding the surface with 120-grit sandpaper.

This woodworking project is about portable reloading plans free. If you want to see more outdoor plans, check out the rest of our step by step projects and follow the instructions to obtain a professional result.