This step by step diy woodworking project is about heavy duty workbench plans. This article features detailed instructions for building a large workbench that is ideal for assembling heavy parts. If you are all about sturdiness and quality, this workbench is ideal for your shop. Make sure you adjust the size of the bench to suit your needs. Take a look over the rest of our woodworking plans, if you want to get more building inspiration.

When buying the lumber, you should select the planks with great care, making sure they are straight and without any visible flaws (cracks, knots, twists, decay). Investing in cedar or other weather resistant lumber is a good idea, as it will pay off on the long run. Use a spirit level to plumb and align the components, before inserting the galvanized screws, otherwise the project won’t have a symmetrical look. If you have all the materials and tools required for the project, you could get the job done in about a day. See all my Premium Plans HERE.

Projects made from these plans

Heavy Duty Workbench Plans

Building-a-heavy-duty-workbench

Cut & Shopping Lists

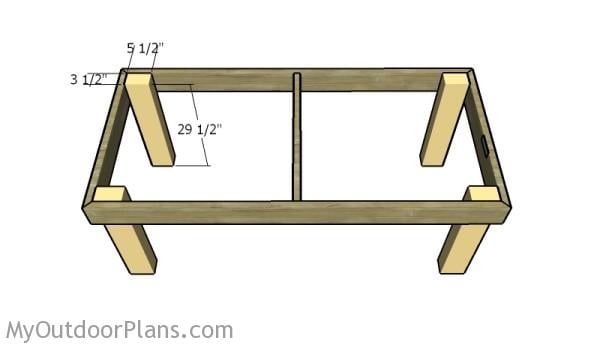

- A – 4 pieces of 4×6 lumber – 29 1/2″ long LEGS

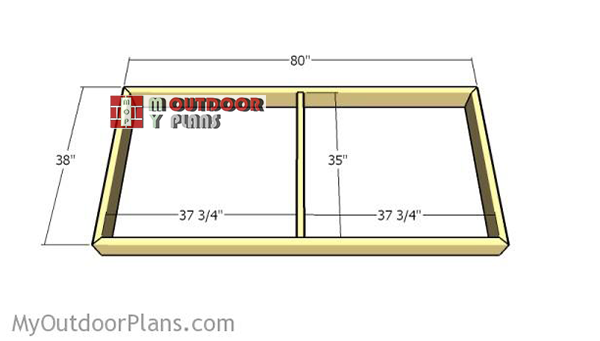

- B – 2 pieces of 2×6 lumber – 80″ long, 2 pieces – 38″ long, 1 piece – 35″ long TOP FRAME

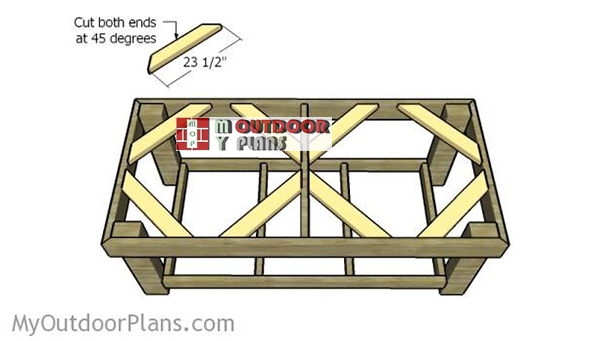

- C – 8 pieces of 2×4 lumber – 23 1/2″ long TOP BRACES

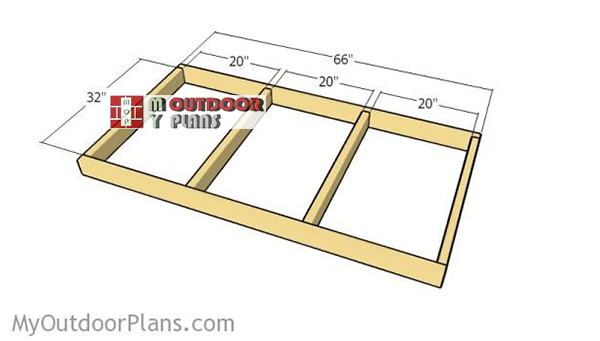

- D – 2 pieces of 2×4 lumber – 66″ long, 4 pieces – 32″ long LOWER FRAME

- E – 1 piece of 3/4″ plywood – 35″x66″ long SHELF

- F – 2 pieces of 3/4″ plywood – 42″x84″ long TABLETOP

- G – 4 pieces of 3/4″ plywood – 4 1/2″x7″ CASTER SUPPORTS

- H – 4 pieces of 6″ caster wheels CASTERS

- 2 pieces of 4×6 lumber – 8′

- 5 pieces of 2×6 lumber – 8′

- 6 pieces of 2×4 lumber – 8′

- 3 pieces of 3/4″ plywood – 4’x8′

- 4 pieces of 6″ caster wheel

- 50 pieces of 3 1/2″ screws

- 100 pieces of 2 1/2″ screws

- 50 pieces of 1 1/4″ screws

- 2″ brad nails

- wood glue, stain/paint

- wood filler

Tools

![]() Hammer, Tape measure, Framing square, Level

Hammer, Tape measure, Framing square, Level

![]() Miter saw, Drill machinery, Screwdriver, Sander

Miter saw, Drill machinery, Screwdriver, Sander

Time

Related

Building a large heavy duty workbench

Building-the-tabletop-frame

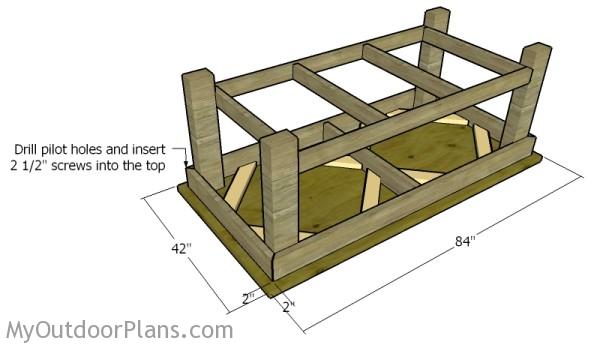

The first step of the project is to build the frame for the tabletop. Cut both ends of the rim components at 45 degrees. Build the components from 2×6 lumber. Make sure the edges are aligned and the corners right-angled.

Drill pilot holes and insert 2 1/2″ screws to lock everything together tightly. Add glue to the joints for a professional result.

Attaching the legs

Use 4×6 lumber for the legs. Drill pilot holes through the frame and insert 3 1/2″ screws into the legs. Make sure the corners are square before inserting the screws, so that the top surface will be horizontal.

Building-the-lower-frame

Build the lower frame from 2×4 lumber. Drill pilot holes through the rim components and insert 2 1/2″ screws into the perpendicular slats. Make sure the corners are square and check if the edges are flush.

Fitting the bottom shelf

Fit the lower frame to the heavy duty workbench and lock it into place with 3 1/2″ screws. Use a spirit level to make sure the frame is horizontal.

Fitting-the-top-frame-braces

Build corner braces for the tabletop from 2×4 lumber. Cut both ends of the braces at 45 degrees. Drill pilot holes and insert 2 1/2″ screws to lock them into place.

Attaching the tabletop

Glue together two pieces of 3/4″ plywood for the tabletop. Clamp them together until the glue dries out. Center the table to the panel, as shown in the diagram. Drill pilot holes through the diagonal braces and pocket holes through the frame of the table and insert 2 1/2″ screws. Add glue to the joints for a professional result.

Fitting the lower shelf

Build the lower shelf from 3/4″ plywood. Fit the panel to the bottom frame and lock it into place with 1 1/4″ screws or nails. Add glue to the joints for a better rigidity.

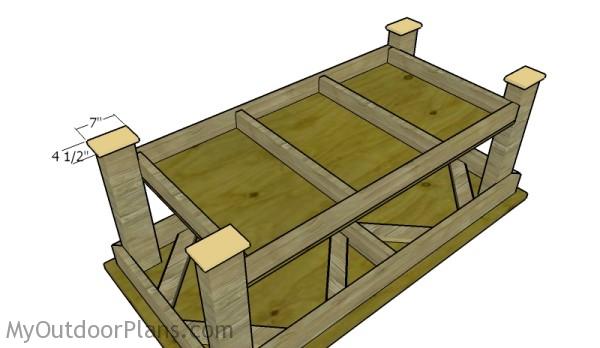

Fitting the caster supports

Cut pieces of 3/4″ plywood for the legs. Lock the supports to the legs with 1 1/4″ screw, after centering them into place.

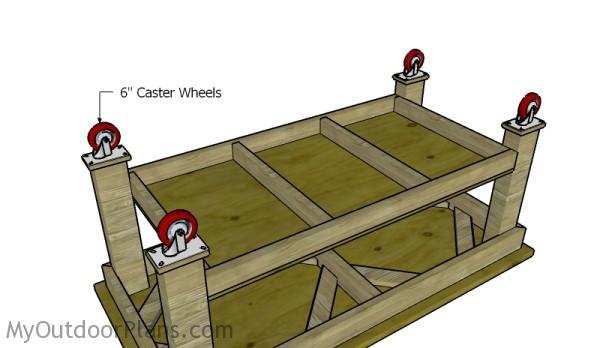

Fitting the caster wheels

Fit 6″ caster wheels to the supports, as shown in the diagram.

Heavy dutty assembling table plans

This is a heavy duty workbench so you can use it for assembling heavy metal parts or for woodworking projects.

Heavy Duty Workbench Plans

Fill the holes with wood putty and let them dry out for a few hours. Smooth the surface with 100-220 grit sandpaper and remove the residues with a damp cloth.

Top Tip: Apply a few coats of paint or stain to the components, to enhance the look of the project. If you want to get PREMIUM PLANS for this project (different design with re-engineered structure), in a PDF format, please press GET PDF PLANS button bellow. Thank you for the support.

This woodworking project was about heavy duty workbench plans free. If you want to see more outdoor plans, check out the rest of our step by step projects and follow the instructions to obtain a professional result.

1 comment

Great project!

How much can it safely hold?

Cheers, Tom