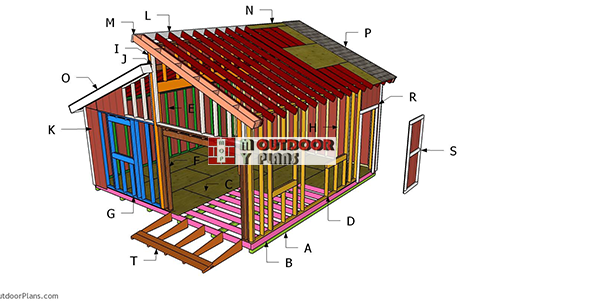

This step by step diy project is about ramp for double pitched shed plans. This is PART 3 of the garden shed project, where I show you everything you want to know about framing the ramp and installing the trims. Take a look over the rest of my woodworking plans, if you want to get more building inspiration. Remember that you need to select the site for the shed with attention and that you have to comply with a few legal regulations.

When buying the lumber, you should select the planks with great care, making sure they are straight and without any visible flaws (cracks, knots, twists, decay). Investing in cedar or other weather resistant lumber is a good idea, as it will pay off on the long run. Use a spirit level to plumb and align the components, before inserting the galvanized screws, otherwise the project won’t have a symmetrical look. If you have all the materials and tools required for the project, you could get the job done in about a day. See all my Premium Plans HERE.

Projects made from these plans

Ramp Plans for Double Pitched Roof Shed

Building-a-20×20-clerestory-shed

Cut & Shopping Lists

- R – 2 pieces of 2×4 lumber – 83″ long, 1 piece – 43″ long JAMBS

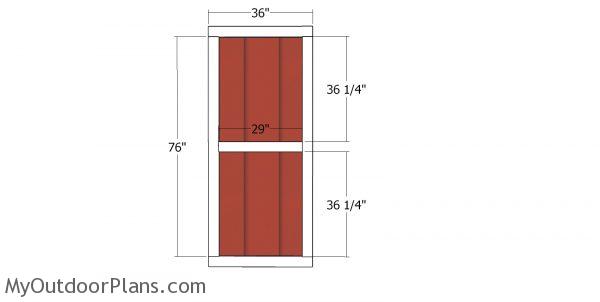

- S – 1 piece of T1-11 siding – 36″x83″ long, 2 pieces of 2×4 lumber – 36 long, 1 piece – 29″ long, 2 pieces – 76″ long 2xDOOR

- T – 5 pieces of 2×10 lumber – 48″ long, 1 piece of 2×4 lumber – 96″ long, 9 pieces of 1×6 lumber – 96″ long RAMP

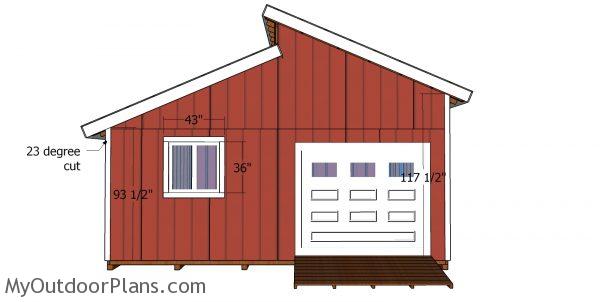

- W – 6 pieces of 1×4 lumber – 36″ long, 6 pieces – 43″ long, 4 pieces – 93 1/2″ long, 4 pieces – 117 1/2″ long TRIMS

- 4 pieces of 1×4 lumber – 10 ft

- 10 pieces of 1×4 lumber – 8 ft

- 3 pieces of 3 ft x 3 ft windows

- 7 pieces of 2×4 lumber – 8 ft

- 3 pieces of 2×10 lumber – 10 ft

- 9 pieces of 1×6 lumber – 8 ft

- 1 piece of T1-11 siding – 4’x8′

- 1 garage door 8 ft x 7 ft

- shed hinges

- 2 1/2″ screws, 3 1/2″ screws, 1 5/8″ screws

- 4d nails, 16d nails, 6d nails

- wood filler , wood glue, stain/paint

Tools

![]() Hammer, Tape measure, Framing square, Level

Hammer, Tape measure, Framing square, Level

![]() Miter saw, Drill machinery, Screwdriver, Sander

Miter saw, Drill machinery, Screwdriver, Sander

Time

Related

- PART 1: 20×20 Storage Shed Plans

- PART 2: 20×20 Shed Roof Plans

- PART 3: 20×20 Shed Doors Plans

Building shed ramp

Ramp frame

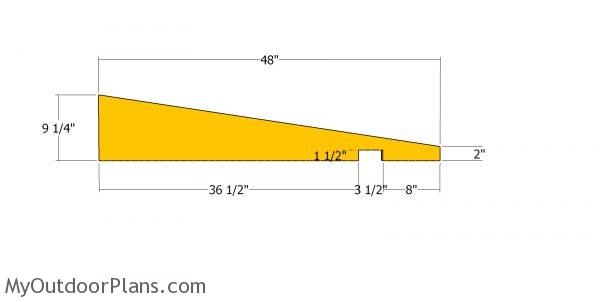

Use 2×10 lumber for the shed ramp joists. Use a circular saw to make the angle cuts to the joists. In addition, make parallel cuts inside the marked area and remove the excess material so you create the cut out. Smooth the edges with sandpaper.

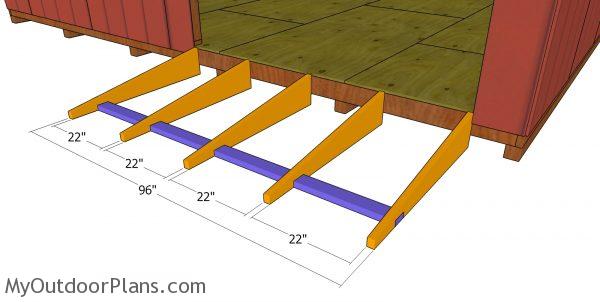

Shed ramp frame

Fit the joists to the floor frame of the shed. Drill pilot holes and insert 3 1/2″ screws to lock the joists into place rightly. Notice the 2×4 slat that joints the joists at the opposite end of the ramp. Drill pilot holes through the joists and insert 3 1/2″ screws into the 2×4 board. It would a be a great idea to lay gravel or concrete pavers under the 2×4 board, to protect the ramp from moisture.

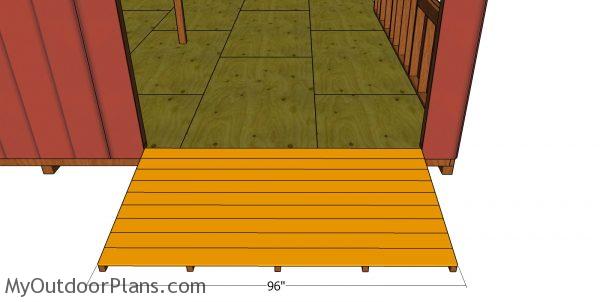

Slats for shed ramp

Attach the 1×6 or 2×6 slats to the ramp frame. Use 2 1/2″ deck screws to lock the slats into place, after drilling the pilot holes.

Side door jambs

Use 2×4 lumber for the door jambs. Attach the 2x4s around the door opening and make sure the edges are flush. Drill pilot holes and insert 2 1/2″ screws to lock the jambs into place tightly.

Side door – 20×20 shed

Use T1-11 siding for the door panel and 2×4 lumber for the door frame. The trick is to assemble the door frame first and then attach the panel and lock it with 1 5/8″ screws. Drill pocket holes and assemble the door frame with 2 1/2″ screws and add glue to the joints.

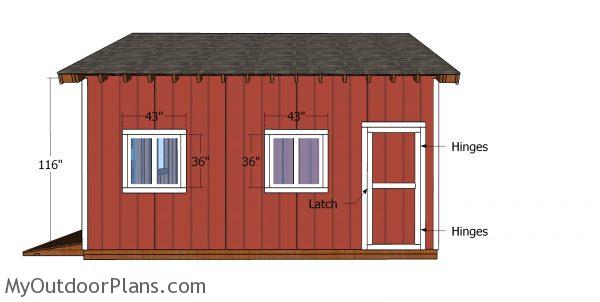

Side wall trims

Fit the door to the opening and lock it to the jambs with hinges. Install a latch, as well. Fit the PVC windows to the openings and then install the trims.

Front view trims

Fit the garage door to the front of the shed, as well as the window.

Clerestory-shed-plans-20×20

Apply a few coats of paint over the exterior of the shed, to enhance the look of the shed and to protect it from the elements.

Double pitched roof shed plans

I hope you enjoyed my tutorial on how to build a shed ramp. This shed is super easy to build and it is also beautiful, so you can add some charm to your garden. Make sure you check out all my woodworking plans HERE.

This woodworking project was about shed ramp plans. If you want to see more outdoor plans, check out the rest of our step by step projects and follow the instructions to obtain a professional result.