This step by step diy project is about 8×12 lean to office shed roof plans. This is PART 2 of the lean to shed project, where I show you how to build the roof, the modern top windows, the exterior panels and the stairs. This shed is a nice addition if you are a freelancer and work from home, or you just need a retreat area where you can read a good book and regain inspiration. Take a look over the rest of my woodworking plans, if you want to get more building inspiration.

When buying the lumber, you should select the planks with great care, making sure they are straight and without any visible flaws (cracks, knots, twists, decay). Investing in cedar or other weather resistant lumber is a good idea, as it will pay off on the long run. Use a spirit level to plumb and align the components, before inserting the galvanized screws, otherwise the project won’t have a symmetrical look. If you have all the materials and tools required for the project, you could get the job done in about a day. See all my Premium Plans HERE.

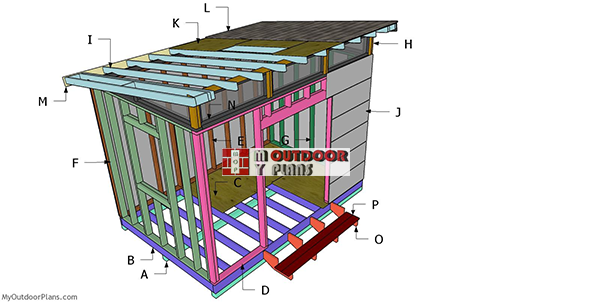

Lean to Roof for a 8×12 Shed Plans

8×12-modern-shed-plans—building

Cut & Shopping Lists

- I – 14 pieces of 2×4 lumber – 120″ long, 6 pieces – 6 1/2″ long RAFTERS

- J – 9 pieces of 3/4″ plywood – 4’x8′ long, 1 piece – 16″x48″ long, 2 pieces – 10 1/2″x48″ long PANELS

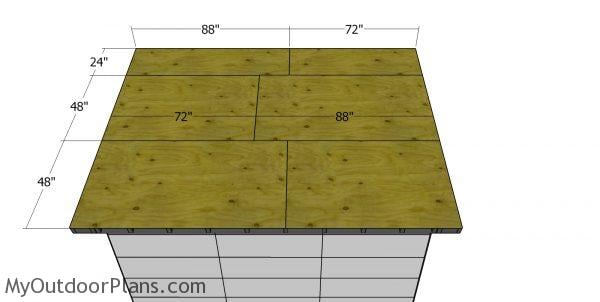

- K – 2 pieces of 1/2″ plywood – 48″x88″ long, 2 pieces – 48″x76″ long, 1 piece – 24″x88″ long, 1 piece – 24″x76″ long ROOF

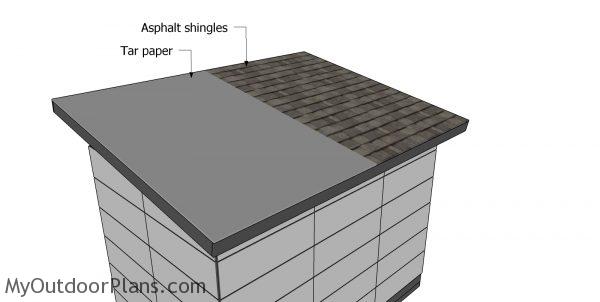

- L – 150 sq ft of tar paper, 150 sq ft of asphalt shingles ROOFING

- M – 2 pieces of 1×6 lumber – 120″ long, 2 pieces – 161 1/2″ long TRIMS

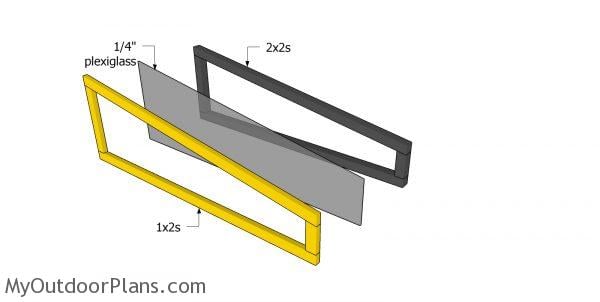

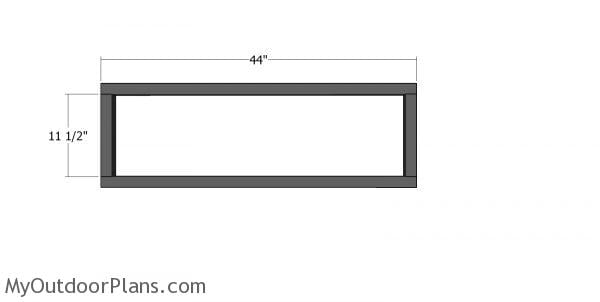

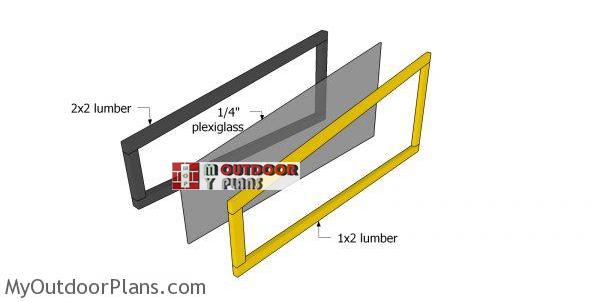

- N – 2 pieces of 2×2 lumber – 44″ long, 2 pieces – 11 1/2″ long, 2 pieces of 1×2 lumber – 44″ long, 2 pieces – 11 1/2″ long, 1 piece of 1/4″ plywood – 44″x14 1/2″ long 3xWINDOW

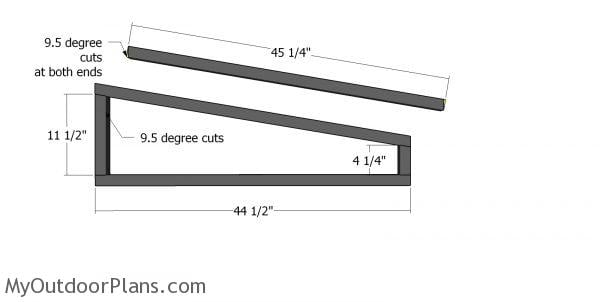

- N – 1 piece of 2×2 lumber – 44″ long, 1 piece – 11 1/2″ long, 1 piece – 45 1/4″ long, 1 piece – 4 1/4″ long, 1 piece of 1×2 lumber – 44″ long, 1 piece – 11 1/2″ long, 1 piece – 45 1/4″ long, 1 piece – 4 1/4″ long, 1 piece of 1/4″ plywood – 44 1/2″x14 1/2″ long 2xWINDOW

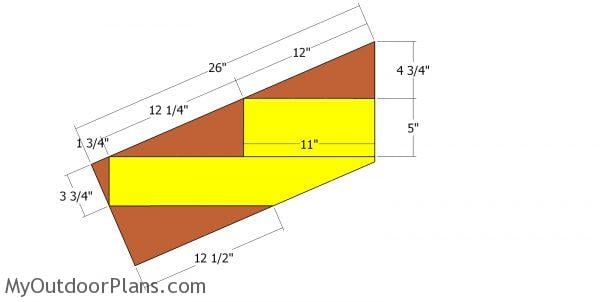

- O – 4 pieces of 2×10 lumber – 26″ long STRINGERS

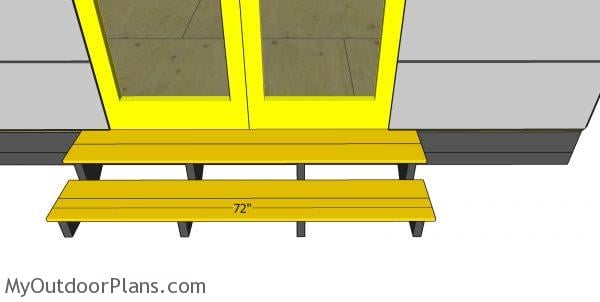

- P – 4 pieces of 1×6 lumber – 72″ long STEPS

- 15 pieces of 2×4 lumber – 10 ft

- 10 pieces of 3/4″ plywood – 4’x8′

- 5 pieces of 1/2″ plywood – 4’x8′

- 2 pieces of 1×6 lumber – 10 ft

- 2 pieces of 1×6 lumber – 14 ft

- 7 pieces of 2×2 lumber – 8 ft

- 7 pieces of 1×2 lumber – 8 ft

- 1 piece of 2×10 lumber – 10 ft

- 2 pieces of 1×6 decking boards – 12 ft

- 1/4″ plexiglass – 3 pieces

- 1/4″ plexiglass – 2 pieces

- 150 sq ft of tar paper, 150 sq ft of asphalt shingles

- 2 1/2″ screws, 3 1/2″ screws, 1 5/8″ screws

- 6d nails, 8d nails

- wood filler , wood glue

- paint

- rafter ties

- nails for rafter ties

- joist hangers

- 5 ft double doors

- 30″x40″ window

Tools

![]() Hammer, Tape measure, Framing square, Level

Hammer, Tape measure, Framing square, Level

![]() Miter saw, Drill machinery, Screwdriver, Sander

Miter saw, Drill machinery, Screwdriver, Sander

Time

Related

- PART 1: 8×12 Lean to Shed Office plans

- PART 2: Lean to shed roof plans

Building a roof for a 8×12 shed

Rafters-for-8×12-office-shed

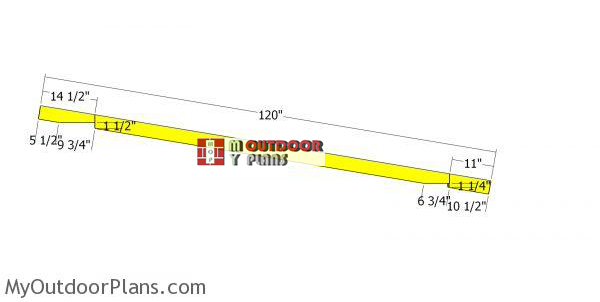

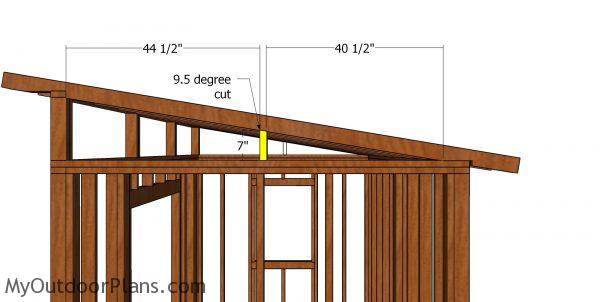

The first step of the PART 2 project is to build the rafters for the lean to shed. Mark the cut lines on the 2×4 beams and get the job done with a circular saw. Smooth the edges with sandpaper.

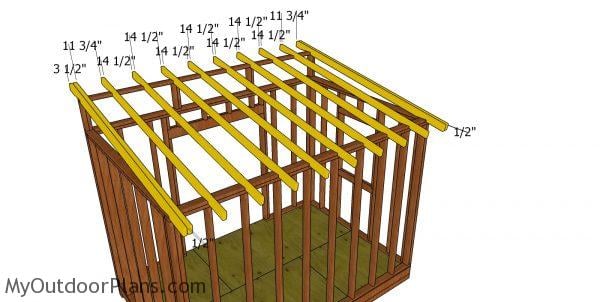

Fitting the rafters

Fit the rafters to the top of the shed and place them equally-spaced, every 16″ on center. Use rafter ties with the appropriate structural nails / screws to lock the rafters into place tightly.

Office shed – side overhangs

Next, you need to build the side overhangs. Use 2×4 lumber for the components. Drill pilot holes and lock the overhangs to the shed roof with 2 1/2″ screws.

Side roof supports

Use 2×4 lumber for the side roof supports. Lock them into place with 2 1/2″ screws and pocket holes.

Fitting the window and double doors – 8×12 modern shed

Fit the double doors to the front opening and the window to the side opening.

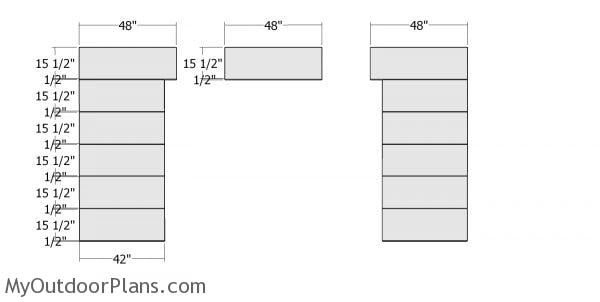

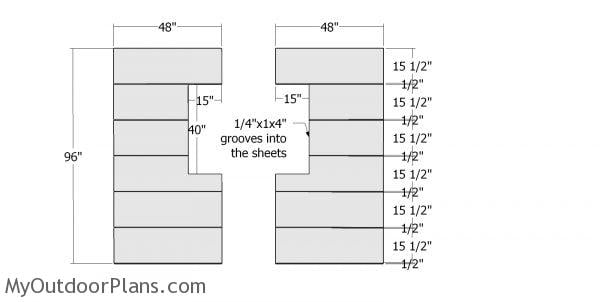

Front wall panels – 8×12 shed

For the exterior walls you can use 3/4″ plywood sheets and make 1/4″x1/4″ grooves with a router, following the pattern shown in the plans. Alternatively, you can go for 1/2″ OSB and cover the shed with house wrap. Last but not least, install cement boards with 1/4″ gaps between them, to create the modern look to your office. For these plans, I will keep it simple and assume you will be using the 3/4″ plywood method.

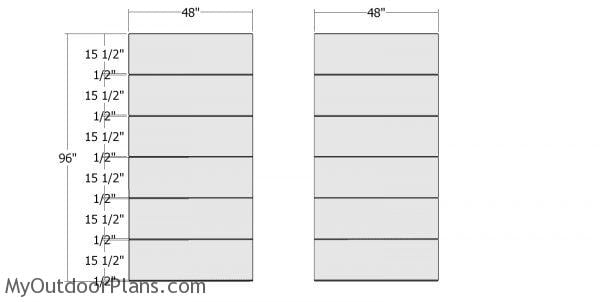

Plain side wall panels – 8×12 modern shed

Make the panels for plain side of the office.

Back wall sheets – 8×12 office shed

Make the panels for the back wall of the moder office shed.

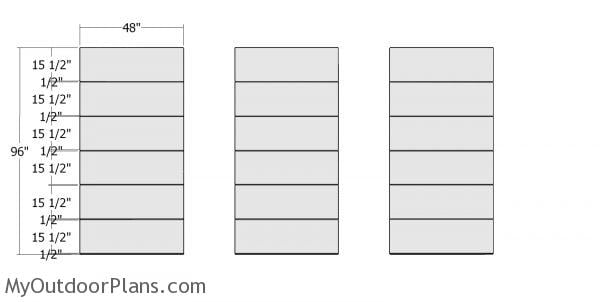

Side wall with window panels

Make the panels for the side wall with window.

Top side wall panels

Make the panels for the side lean to areas.

Fitting the exterior panels – 8×12 shed

Continue the project by attaching the 3/4″ plywood sheets to the exterior of the shed. Align the edges flush and use 8d nails to lock the panels to the framing, every 8″.

Roof sheets – 8×12 office shed

Attach the 1/2″ plywood sheets to the roof of the lean to shed. Align the edges flush and secure them to the rafters using 1 5/8″ screws. Make sure there are no gaps between the sheets for a professional result.

Side roof trims

Fit the 1×6 trims to the sides of the roof. Attach the trims to the overhangs with 6d nails.

Front and back roof trims

Fit a 1×6 trim to the front of the lean to shed, as shown in the diagram. Align the edges with attention and secure it to the ends of the rafters using 6″ finish nails.

Fitting the roofing – 8×12 modern shed

Cover the roof of the shed with roofing felt, making sure the strips overlap at least 2″. Secure the tar paper to the plywood sheets with roofing staples. Fit the side drip edges over the roofing felt, while the bottom drip edges should be fit under. Afterwards, attach the asphalt shingles to the roof, starting with the left bottom side of the roof. Read the manufacturer’s instructions to understand how to install the shingles into place properly.

Side window frames

Use 2×2 lumber for the side top windows. Cut the components for the window frames from 2×2 lumber. Drill pilot holes and insert 2 1/2″ screws to assemble the frames. Align the edges flush.

Assembling the side roof windows

Use 1/8″ or 1/4″ plexiglass for the windows. Attach the plexiglass to the window frame with construction glue. Use 1×2 lumber for the trims. Add construction glue to lock them into place tightly.

Top side wall frame

Build the windows for the top of the front wall. Assemble the frame with 2x2s and 2 1/2″ screws. Make sure the corners are square and align the edges flush.

Assembling-the-windows

Use 1/8″ or 1/4″ plexiglass for the windows. Attach the plexiglass to the window frame with construction glue. Use 1×2 lumber for the trims. Add construction glue to lock them into place tightly.

Fitting the top front windows – modern shed

Next, attach the windows to the front and sides of the office shed. Drill pilot holes through the 2×2 frames and insert 2 1/2″ screws to lock them to the structure.

Building the stringer boards

Use 2×10 lumber for the front stairs stringers. Mark the cut lines to the boards and get the job done with a circular saw. Smooth the edges flush.

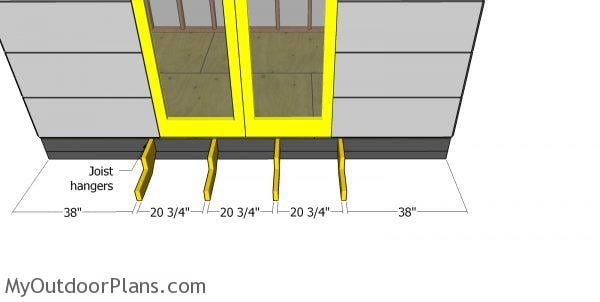

Fitting the stringer boards

Fit the stringer boards to the front of the shed. Use joist hangers to lock the stringers to the floor frame of the office shed.

Fitting the boards to the steps

Fit the 1×6 decking boards to the stringers. Make sure you have equal overhangs on both sides. Drill pilot holes through the boards and insert 1 5/8″ screws to lock them into place tightly.

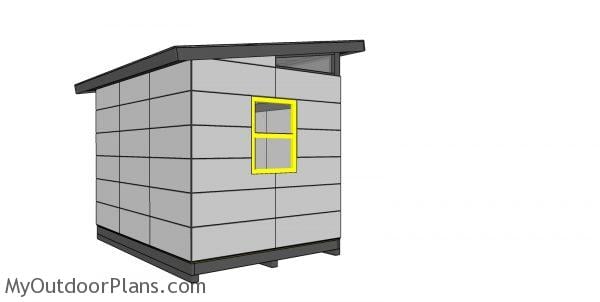

8×12 Modern Office Shed Plans – side view

Seen from the side, this office shed has that unique and distinctive modern look that attracts you to it and creates a cozy atmosphere that is ideal for work inspiration.

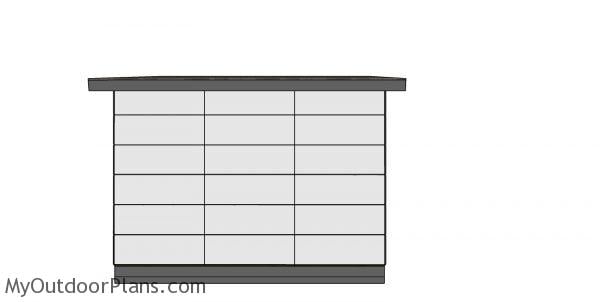

8×12 Modern Office Shed Plans – back view

Fill the holes with wood putty and let it dry out for a day. Smooth the surface and then apply a few coats of paint / stain to enhance the look of the backyard office.

8×12 Modern Office Shed – diy plans

Fitting the exterior panels – 8×12 shed

You can build this office shed with a modern design in one week, if you know the basic woodworking skills and have a few tools. You should be confident you can pull it off and save a ton of money during the process. I have more modern shed plans, so take a look HERE. See a list of all the projects that I have on my blog: HERE.

This woodworking project was about 8×12 lean to office shed roof plans. If you want to see more outdoor plans, check out the rest of our step by step projects and follow the instructions to obtain a professional result.

4 comments

can i get the PDF for the 8×12 office shed.

Thanks!

Vinay

I cant find the pdf file to download the 8×12 shed plan…. where is the link please?

Thanks JP

Read the FAQs: https://myoutdoorplans.com/faq/

Nice design but I have a concern about the framing of the taller 12’ wall that houses the windows. The single 2×4 top plate spanning 4’ between the cripple studs seems inadequate and prone to flexing under the roof load. Are you calculating for any snow load? Even just the roof weight would appear to cause that top plate to flex. Thoughts?