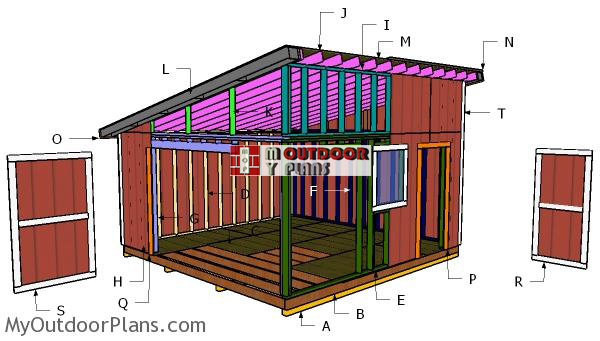

This step by step diy project is about 16×16 lean to shed plans. I have designed this large lean to shed, so you can build a nice outdoor workshop or office, while keeping the costs down. This shed features double doors on the side and a nice 3′ door to the front. Moreover, you should get a lot of light inside the shed, as it has two large windows on the front wall. Make sure you read the local building codes and follow the legal requirements. Take a look over the rest of my woodworking plans, if you want to get more building inspiration.

When buying the lumber, you should select the planks with great care, making sure they are straight and without any visible flaws (cracks, knots, twists, decay). Investing in cedar or other weather resistant lumber is a good idea, as it will pay off on the long run. Use a spirit level to plumb and align the components, before inserting the galvanized screws, otherwise the project won’t have a symmetrical look. See all my Premium Plans HERE.

Projects made from these plans

16X16 Lean to Shed – Free DIY Plans

Building-a-16×16-lean-to-shed

Cut & Shopping Lists

- A – 4 pieces of 4×4 lumber – 192″ long SKIDS

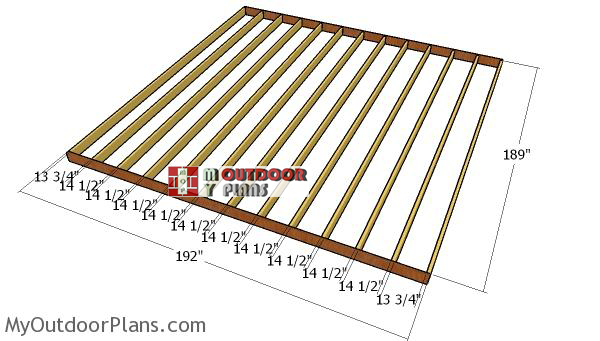

- B – 2 pieces of 2×6 lumber – 192″ long, 13 pieces – 185″ long FLOOR

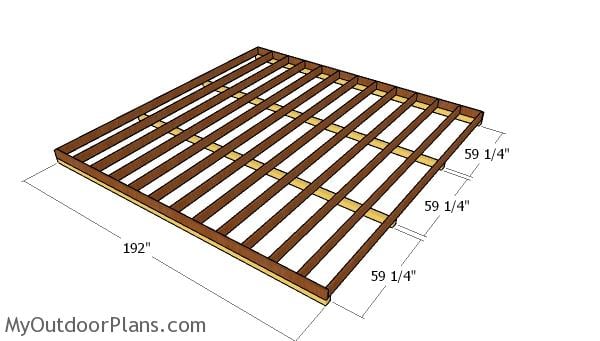

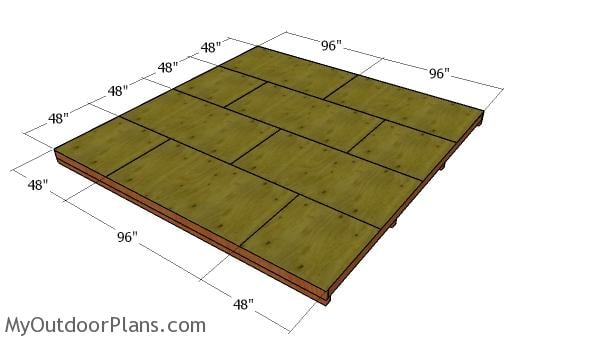

- C – 6 pieces of 3/4″ plywood – 48″x96″ long, 4 pieces – 48″x48″ long FLOORING

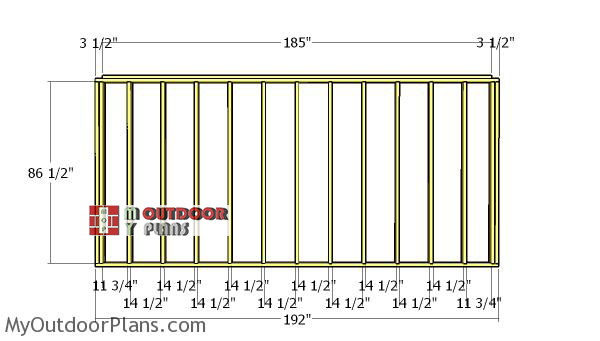

- D – 2 pieces of 2×4 lumber – 192″ long, 1 piece – 185″ long, 15 pieces – 86 1/2″ long BACK WALL

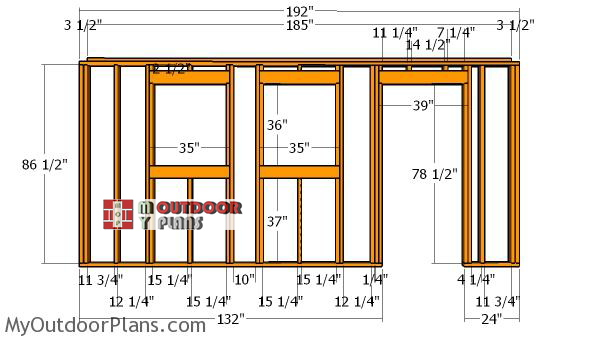

- E – 1 piece of 2×4 lumber – 132″ long, 1 piece – 24″ long, 1 piece – 185″ long, 1 piece – 192″ long, 13 pieces – 86 1/2″ long, 6 pieces – 37″ long, 4 pieces – 36″ long, 10 pieces – 2 1/2″ long, 2 pieces – 78 1/2″ long, 8 pieces of 2×6 lumber – 35″ long, 2 pieces – 39″ long FRONT WALL

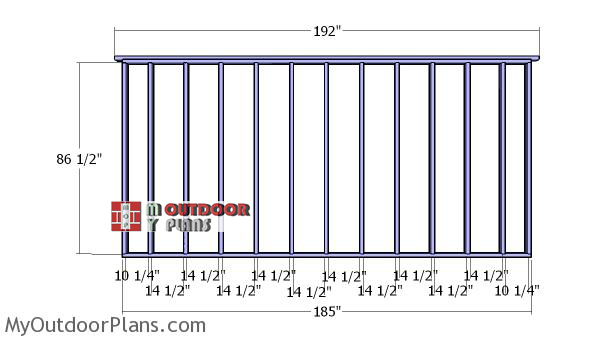

- F – 2 pieces of 2×4 lumber – 185″ long, 1 piece – 192″ long, 13 pieces – 86 1/2″ long SIDE WALL

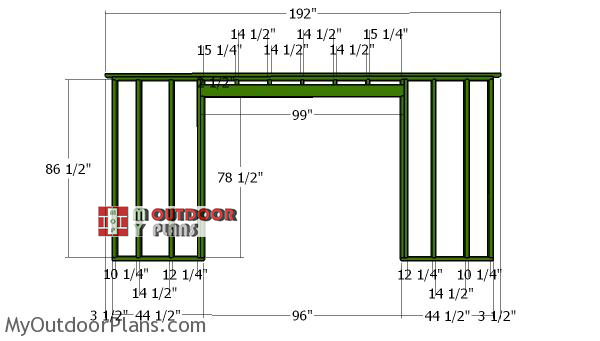

- G – 2 pieces of 2×4 lumber – 44 1/2″ long, 1 piece – 192″ long, 1 piece – 185″ long, 8 pieces – 86 1/2″ long, 2 pieces – 78 1/2″ long, 7 pieces – 2 1/2″ long, 2 pieces of 2×6 lumber – 99″ long SIDE WALL WITH DOOR

- G – 14 pieces of T1-11 siding – 48″x91″ long, 2 pieces – 11″x48″ long SIDING

- 4 pieces of 4×4 lumber – 192′

- 15 pieces of 2×6 lumber – 16′

- 8 pieces of 3/4″ plywood – 4’x8′

- 11 pieces of 2×4 lumber – 16′

- 60 pieces of 2×4 lumber – 8′

- 4 pieces of 2×4 lumber – 6′

- 1 piece of 2×4 lumber – 8′

- 2 pieces of 2×6 lumber – 10′

- 16 pieces of T1-11 siding – 4’x8′

- 6d nails, 2 1/2″ screws, 3 1/2″ screws

- wood filler , wood glue, stain/paint

Tools

![]() Hammer, Tape measure, Framing square, Level

Hammer, Tape measure, Framing square, Level

![]() Miter saw, Drill machinery, Screwdriver, Sander

Miter saw, Drill machinery, Screwdriver, Sander

Time

Related

- PART 1: 16×16 Lean to Shed Plans

- PART 2: 16×16 Lean to Shed Roof Plans

- PART 3: 16×16 Lean to Shed Door Plans

It’s that easy to build a 16×16 lean to shed – Video!

Building a 16×16 lean to shed

Building-the-floor-frame

The first step of the project is to build the floor frame for the storage shed. Cut the components at the right dimensions and then lay them on a level surface. Drill pilot holes through the rim joists and then insert 3 1/2″ screws into the perpendicular beams. Place the joists every 16″ on center, as in the diagram. Make sure the corners are square and the edges flush, before inserting the screws.

Fitting the skids

Select the location for the shed and make sure you remove the vegetation layer. Level the ground thoroughly and then fit the 4×4 skids under the floor frame. If you want to lift the floor frame even more, use 6×6 lumber. Align the edges and use rafter ties to secure the skids to the frame of the floor. Use a spirit level to make sure the frame is horizontal in all directions. Check out the local building codes before building the shed, so you make sure you comply with the requirements.

Fitting the floor sheets

Fit 3/4″ tongue and groove plywood sheets to the floor frame. Align the edges flush and insert 1 5/8″ screws, every 8″ along the framing. Leave no gaps between the sheets for a professional result. Use the pattern shown in the diagram, for a professional result.

Front-wall-frame

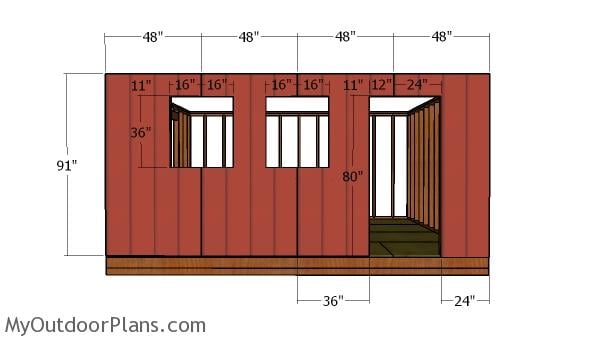

Continue the project by assembling the front wall frame. Use 2×4 lumber for the front wall frame. Use 2×6 lumber and 1/2″ plywood for the double header. Drill pilot holes through the plates and insert 3 1/2″ screws into the studs. Make sure the corners are square and align the edges flush.

You can adjust the size of the door opening to suit your needs. You can adjust the size of the opening to suit your needs. Use 1/2″ plywood blockings between the double studs that are placed at both ends of the wall frame.

Back-wall-frame

Build the frame for the back wall from 2×4 lumber. Cut the components from 2×4 lumber at the right dimensions. Drill pilot holes through the plates and insert 3 1/2″ screws into the studs. Make sure the corners are square and place the studs every 16″ on center.

Side-wall-frame

Build the side wall frame for the shed using the same techniques described above and the information from the diagram. Place the studs every 16″ on center. Align the edges with attention and make sure the corners are square. Lay all the components on a level surface when assembling the shed wall, so you get a professional result.

Side-wall-with-door-frame

Assemble the opposite wall for the lean to shed, using the information from my free plans. As you can see in the diagram, I suggest you to frame double doors, so you have an easy access inside with large items. You can adjust the size of the opening or you can remove it altogether, according to your needs. Use 2×6 lumber and 1/2″ plywood for the double header.

Assembling the shed frame

Fit the wall frames to the floor of the shed. Align the edges with attention and plumb the walls with a spirit level. Drill pilot holes through the bottom plates and insert 3 1/2″ screws into the floor. Lock the adjacent walls together tightly using 3 1/2″ screws.

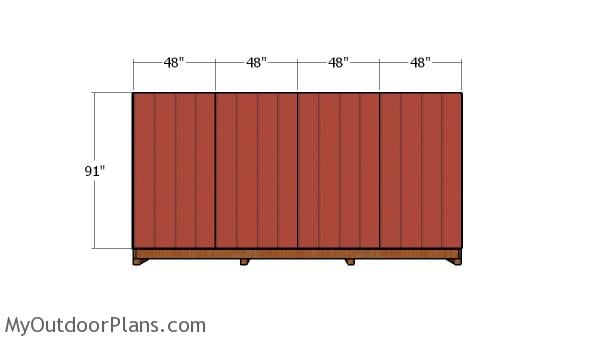

Side wall siding panels

Fit T1-11 siding panels to the plain side wall of the shed. Align the edges flush and then insert 2″ nails, every 8″ along the framing. Leave no gaps between the sheets for a professional result.

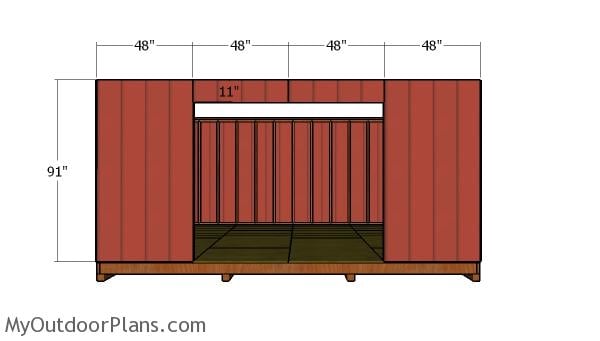

Side wall with door siding panels

Fit the T1-11 siding sheets to the other side of the shed, using the information from the diagram. As you can easily notice in the diagram, you need to make a few cuts, so you can fit the sheets to the wall frames.

Front wall siding panels

Fit the siding sheets to the front of the shed, as well. Make a few cuts to the sheets so you can fit them around the window and door openings. Insert 2″ nails, every 8″ along the frame, so you lock the sheets into place tightly.

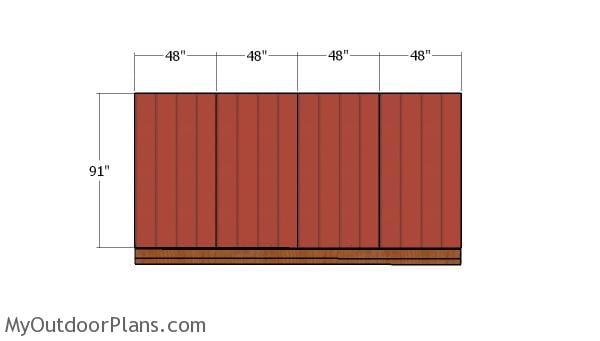

Back wall siding panels

In order to attach the siding sheets to the back of the shed you need to make a few cuts. Mark the cut lines and then get the job done with a circular saw. Insert 2″ nails, every 8″ along the framing. You will use the cutout panel for the door.

How to build a 16×16 lean to shed

This is a relatively large shed with a lean to roof, so you can build this project even if you have a narrow yard. You can use this large shed as a office or as a workshop, with minimum modifications to my design and low investments into quality materials for the interior.

16×16 lean to shed plans – Back view

Make sure you take a look over PART 2 and PART 3 of the project, so you learn how to build the lean to roof and how to build the decorative trims. I have lots of other shed projects on the site so I recommend you to browse through all alternatives before starting the building project. See all my shed projects HERE.

This woodworking project was about 16×16 lean to shed plans free. If you want to see more outdoor plans, check out the rest of our step by step projects and follow the instructions to obtain a professional result.

11 comments

i noticed that the boards for the roof rafters need to be 20 feet long. do you know where a good place to get them would be? Places like lowes and home depot only carry 16 foot length boards, are they something that i would have to go to a lumber mill to get? i have no idea where to get 20 foot lumber at, please advise.

Yes, a lumber mill would be a good choice, unless you don’t find them at the local DIY store on order.

First off, Ty for the plans you post on here :). just finish your 16×16 gable roof shed, easy plans to follow. looking to build this, question: will the 2×6 used on the roof support give you enough support? My understanding is a 2×6 will only support a span of 6 feet? TY

Please read the local codes for that. It all depends on the winds and snow load.

Love the plans on this website! Built my 16×16 shed to the plans and it turned out fantastic. I modified it a bit to include a standard 32×80 inch door that closes into the side barn door. I included a separate small room in the front of the shed (the roof of the room serves as a loft). Only place I messed up was forgetting to cut 3/4 inch of a 16 foot section (the 16 ft lumber pieces came were 16 3/4. I ended up being able to hide it with trim. You can’t really tell unless you look for it. Otherwise, turned out great. Extremely sturdy. The only think I would do different is maybe use thicker panels for the roof. Still – I don’t think the roof will have a problem with a heavy snowfall (I’ll make sure to knock it off before it gets too thick just as a safe measure). Added electrical and insulation. Very happy with the results.

I must be blind… I can’t figure out how to download the plans?

Folks, you make it really complicated to just buy what I want…

I how can I just buy the blueprint

in download it

Read the blog FAQs

What is the total cost of materials?On average. I understand that the cost will very depending where you get it from.

In the range of 3000 usd