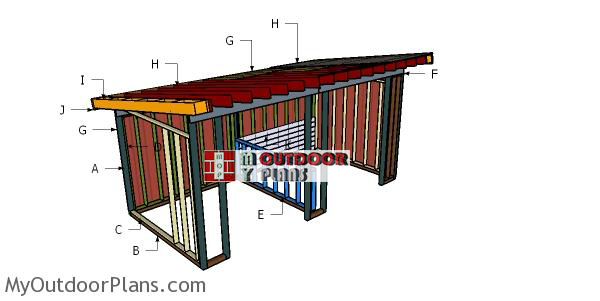

This step by step diy woodworking project is about 10×20 run in shed roof plans. This article is PART 2 of the run in shed project, where I show you how to frame the lean to roof and how to fit the decorative trims. The roof has a 2:12 roof pitch. Take a look over PART 1 of the plans to see how to build the frame of the shed. Make sure you check out the rest of woodworking plans to see alternatives and more projects for your garden.

When buying the lumber, you should select the planks with great care, making sure they are straight and without any visible flaws (cracks, knots, twists, decay). Investing in cedar or other weather resistant lumber is a good idea, as it will pay off on the long run. Use a spirit level to plumb and align the components, before inserting the galvanized screws, otherwise the project won’t have a symmetrical look. If you have all the materials and tools required for the project, you could get the job done in about a day. See all my Premium Plans HERE.

Projects made from these plans

10×20 Run In Shed Roof Plans

Building-a-10×20-run-in-shed

Cut & Shopping Lists

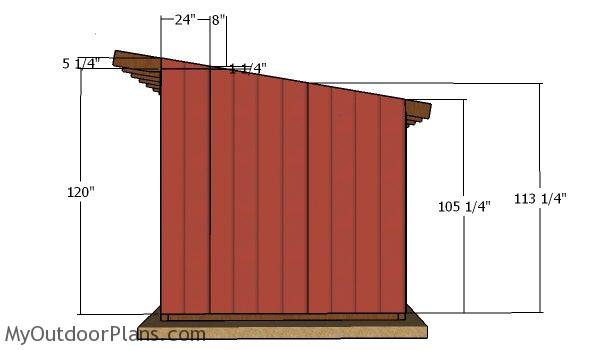

- G – 2 pieces of T1-11 siding – 48″x120″ long, 2 pieces – 24″x120″ long, 2 pieces – 48″x113 1/4″ long SIDING

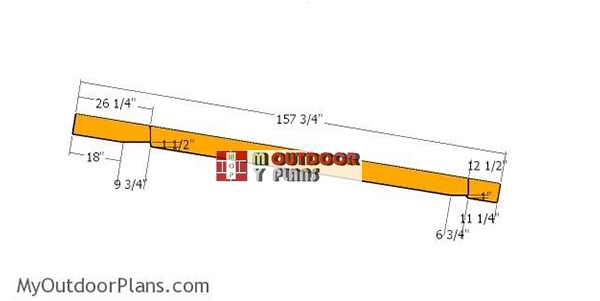

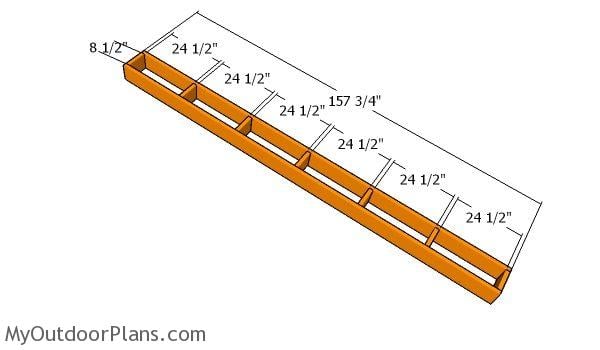

- H – 16 pieces of 2×8 lumber – 157 3/4″ long RAFTERS

- I – 2 pieces of 2×8 lumber – 157 3/4″ long, 7 pieces – 8 3/8″ long 2xOVERHANG

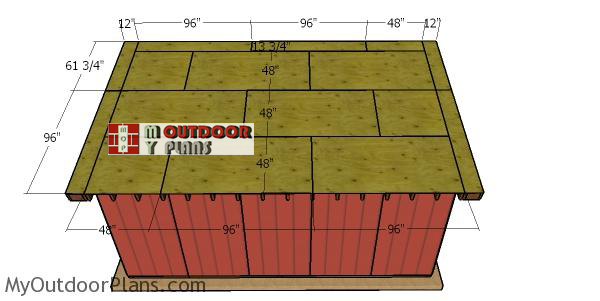

- G – 2 pieces of 3/4″ plywood – 12″x96″ long, 2 pieces – 12″x61 3/4″ long, 6 pieces – 48″x96″ long, 3 pieces – 48″x48″ long, 1 piece – 13 3/4″x48″ long, 2 pieces – 13 3/4″x96″ long ROOF SHEETS

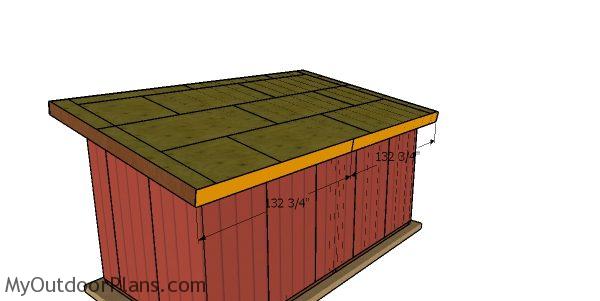

- J – 2 pieces of 1×10 lumber – 157 3/4″ long, 4 pieces – 132 3/4″ long TRIMS

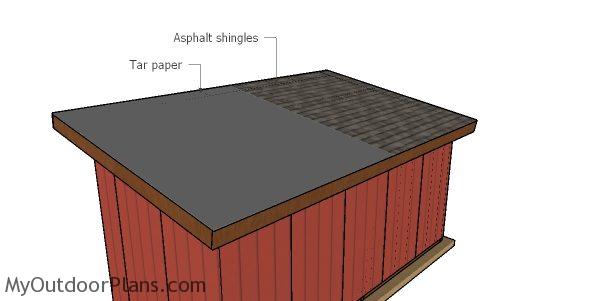

- H – 350 sq ft of tar paper, 350 sq of asphalt shingles ROOFING

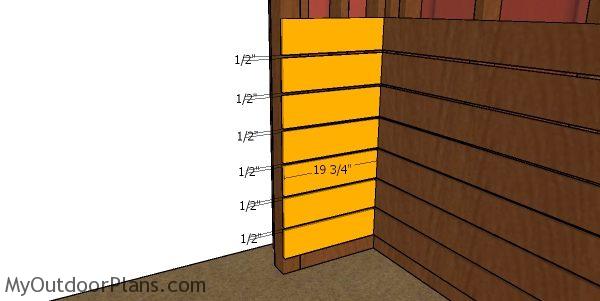

- K – 14 pieces of 1×6 lumber – 113 1/4″ long, 14 pieces – 113″ long, 14 pieces – 19 3/4″ long KICK BOARDS

- 21 pieces of 2×8 lumber – 14′

- 28 pieces of 1×6 lumber – 10′

- 4 pieces of 1×6 lumber – 8′

- 4 pieces of 1×10 lumber – 12′

- 2 pieces of 1×10 lumber – 14′

- 10 pieces of 3/4″ plywood – 4’x8′

- 5 pieces of 5/8″ T1-11 siding – 4’x10′

- 350 sq ft of tar paper, 350 sq of asphalt shingles

- rafter ties

- 2 1/2″ screws, 3 1/2″ screws, 1 5/8″ screws

Tools

![]() Hammer, Tape measure, Framing square, Level

Hammer, Tape measure, Framing square, Level

![]() Miter saw, Drill machinery, Screwdriver, Sander

Miter saw, Drill machinery, Screwdriver, Sander

Time

![]() One week

One week

Building a 10×20 lean to shed roof

Building-the-rafters-for-10×20-run-in-shed

Build the rafters from 2×8 lumber. Make notches to the rafters, using the information from the diagram. Smooth the recesses with sandpaper.

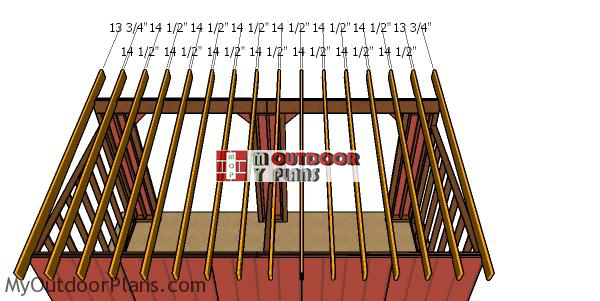

Fitting-the-rafters-to-the-10×20-run-in-shed

Fit the rafters to the top of the compact run in shed. Drill pilot holes and lock the rafters to the structure with screws and rafter ties. Place the rafters every 16″ on center.

Side siding panels – 10×16 run in shed

Attach T1-11 siding to the sides of the run in shed. Make cuts to the panels. Use 6d brad nails to lock the sheets into place tightly. Insert the nails every 8″ along the wall framing.

Building the overhangs – 10×16 run in shed

Use 2×6 lumber for the side overhangs. Drill pilot holes through the rafters and insert 3 1/2″ screws into the blockings.

Fitting the side roof overhangs

Fit the overhangs to the sides of the run in shed and align the edges flush. Drill pilot holes and insert 3 1/2″ screws to lock them into place tightly.

Fitting-the-roof-sheets-10×20-2-stall-horse-shed

Cut the 3/4″ plywood sheets at the right dimensions, as shown in the diagram. Align the edged with attention and leave no gaps between the sheets. Insert 1 5/8″ screws, every 8″ along the framing.

Side roof trims – 10×10 run in shed

Fit 1×10 trims to the sides of the lean to roof. Use 2 1/2″ nails to secure the trims into place tightly.

Fitting the front and back roof trims – 10×20 run in shed

Attach 1×10 trims to the front and back of the roof.

Fitting the roofing – 10×20 shed

Cover the roof of the shed with roofing felt, making sure the strips overlap at least 2″. Secure the tar paper to the plywood sheets with roofing staples. Install the asphalt shingles to the roof of the run in shed. Install drip edges to protect the trims.

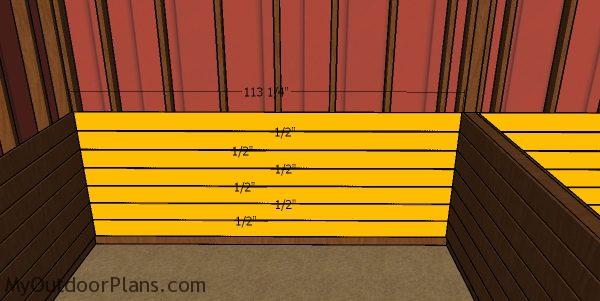

Side wall kickboards – 10×20 run in shed

Attach the 1×6 kickboards to the interior of the shed. Use a 1/2″ spacer to create even gaps between the boards. Use 1 5/8″ screws to secure the boards to the studs.

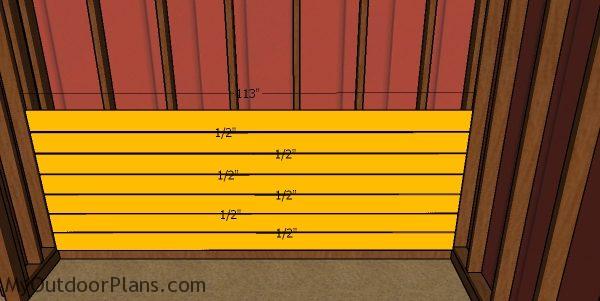

Back wall kickboards – 10×20 run in shed

Fit the 1×6 boards to the back walls. You can adjust the distance between the boards to suit your needs.

Front wall kickboards – 10×20 run in shed

Last but not least, you need to take care of the finishing touches. Fill the holes with wood putty and smooth the surface with 120-220 grit sandpaper. Apply a few coats of paint or stain to trims and to the exterior of the walls.

How-to-build-a-10×20-run-in-shed

Fill the holes with wood putty and let them dry out for a few hours. Smooth the surface with 100-200 grit sandpaper and remove the residues with a damp cloth.

Top Tip: Check out PART 1 of the project, to learn how to build the frame for the 10×20 run in shed.

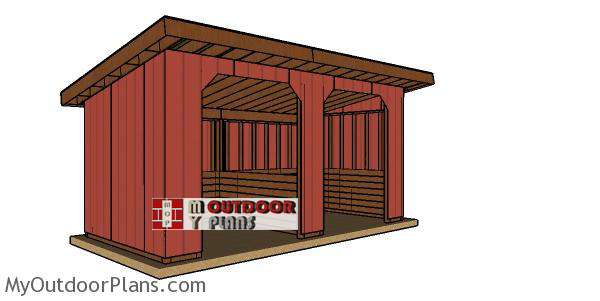

This woodworking project was about 10×20 run in shelter plans. If you want to see more outdoor plans, check out the rest of our step by step projects and follow the instructions to obtain a professional result. See a list with my plans HERE.

EXPLORE MORE IDEAS FOR:

|

|

|

|