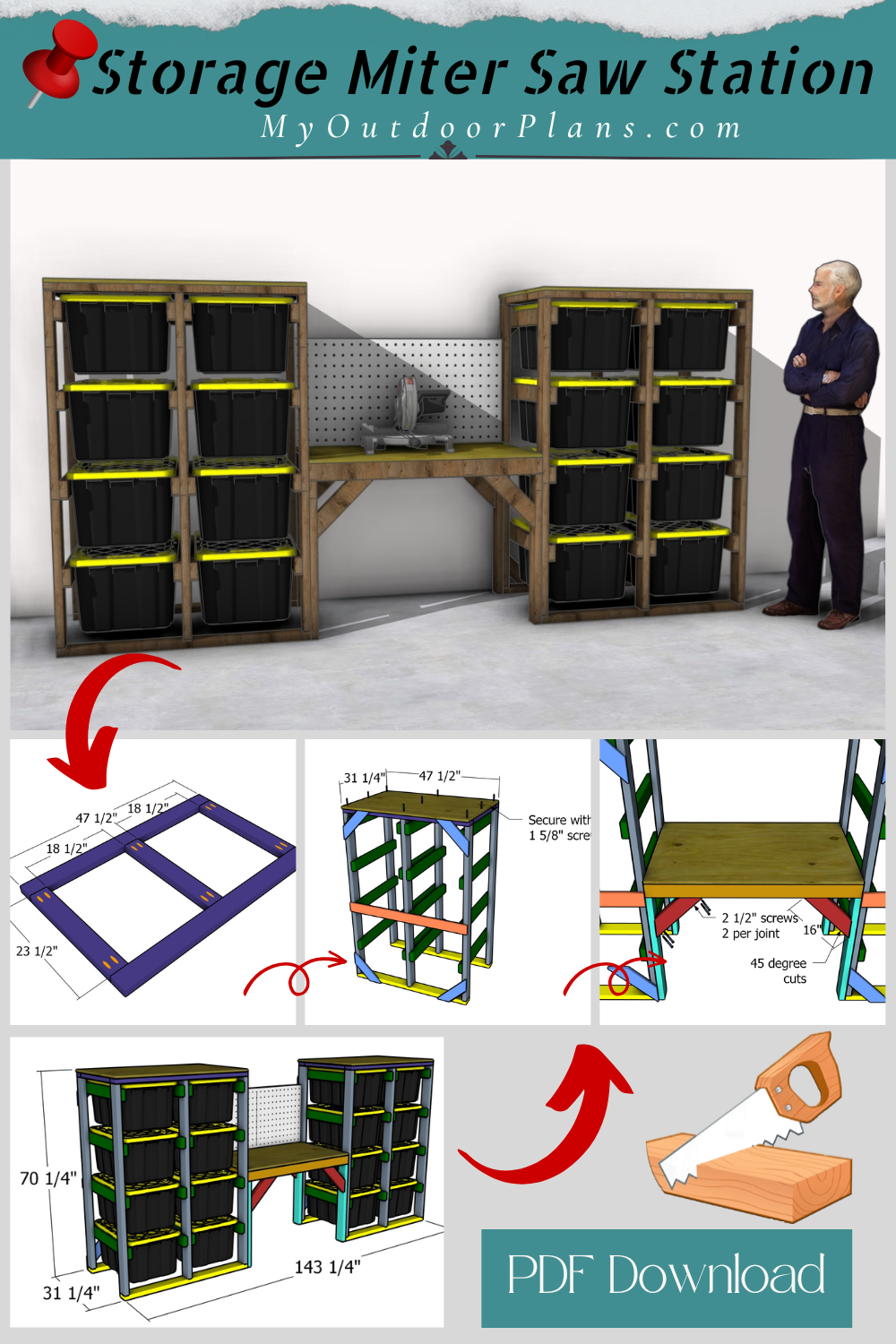

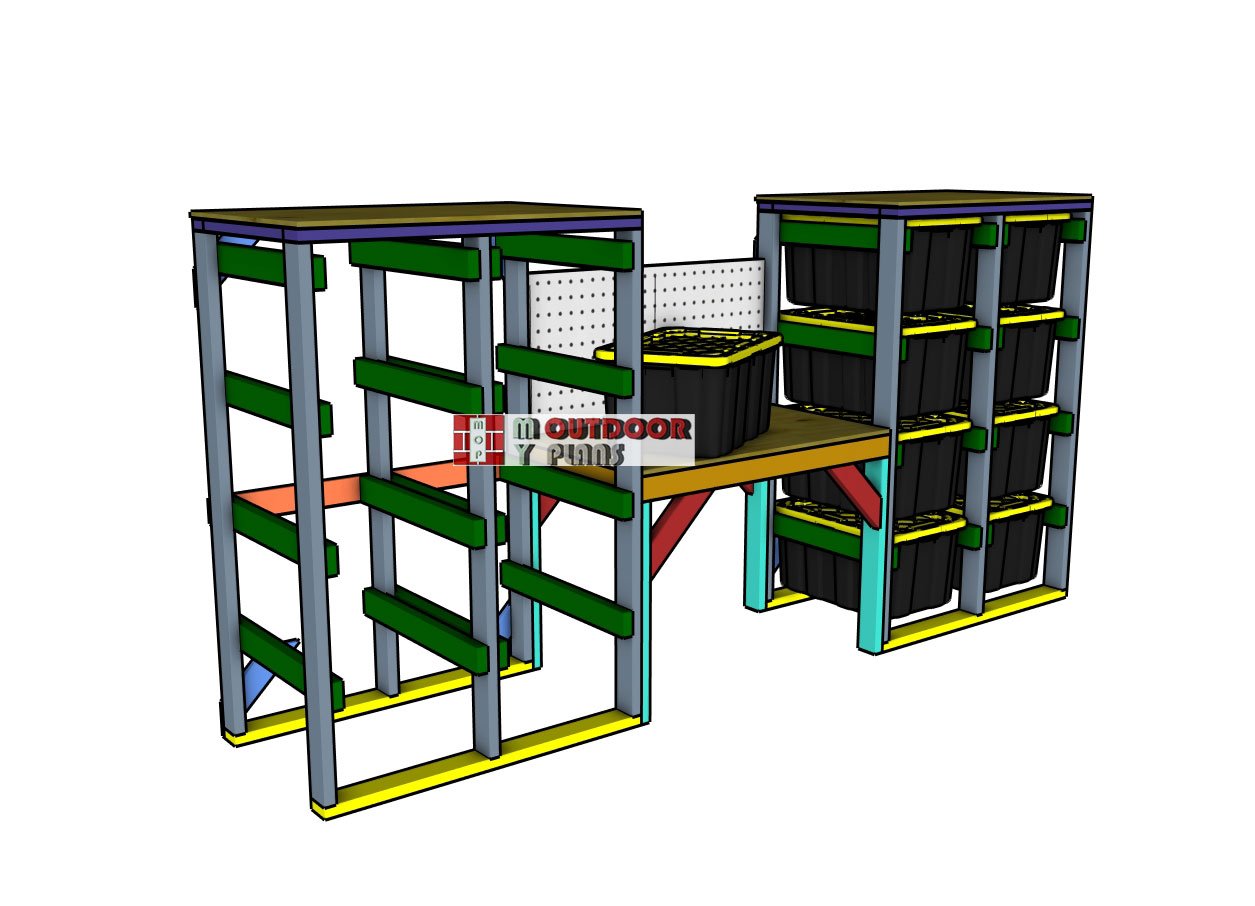

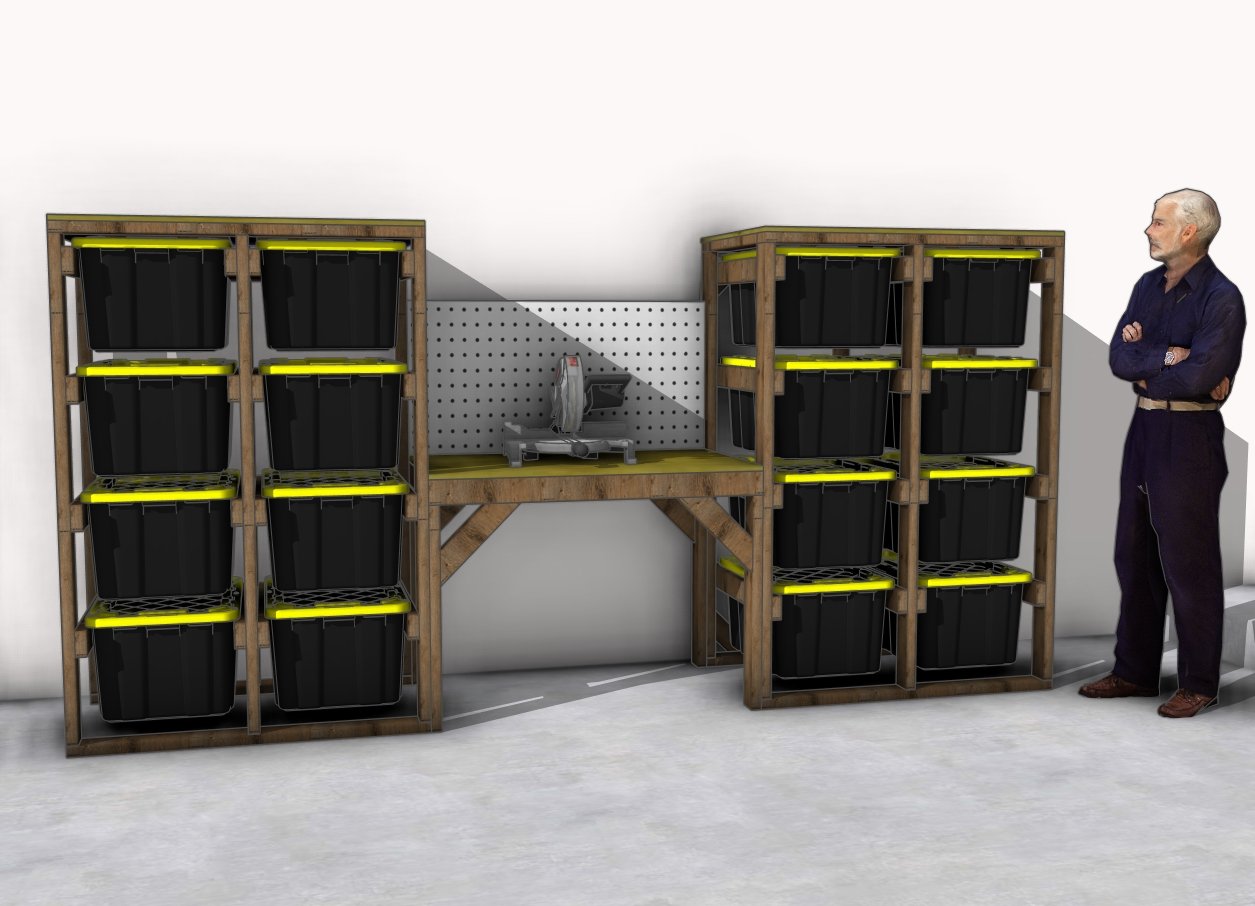

Transform your workshop into a powerhouse of efficiency with this DIY tote storage miter saw station plans! This versatile design not only provides a sturdy, functional workspace for your miter saw but also offers ample storage for up to 16 large totes and a pegboard for organizing tools. Whether you’re tackling big woodworking projects or just want to bring order to your garage, this project is the perfect blend of practicality and craftsmanship. Let’s take a look and create a station that will elevate your workspace to the next level!

To ensure the success of your miter saw station project, focus on precision and preparation. Measure twice and cut once to avoid errors, and always drill pilot holes to prevent splitting the wood. Assemble on a flat, level surface to keep everything square and stable. Choose quality materials for durability, and customize the design to fit your tools and workflow. Sand all surfaces for a smooth finish, and apply paint or a protective coating to enhance both the look and longevity of your station. Take your time during assembly, and plan your storage layout as you build to maximize efficiency and functionality. With these tips, you’ll create a professional, durable, and organized workspace! Take a look over the rest of my woodworking plans, if you want to get more building inspiration. Premium Plans for this project available in the Shop.

For this project, I recommend using cedar or hardwood for their durability and natural resistance to the elements. Cedar is a fantastic option because it’s lightweight, rot-resistant, and has a beautiful, rustic look. Hardwood, on the other hand, provides superior strength and longevity, making your project a sturdy and stylish addition to your home.

Projects made from these plans

DIY Tote Storage Miter Saw Station – Free DIY Plans

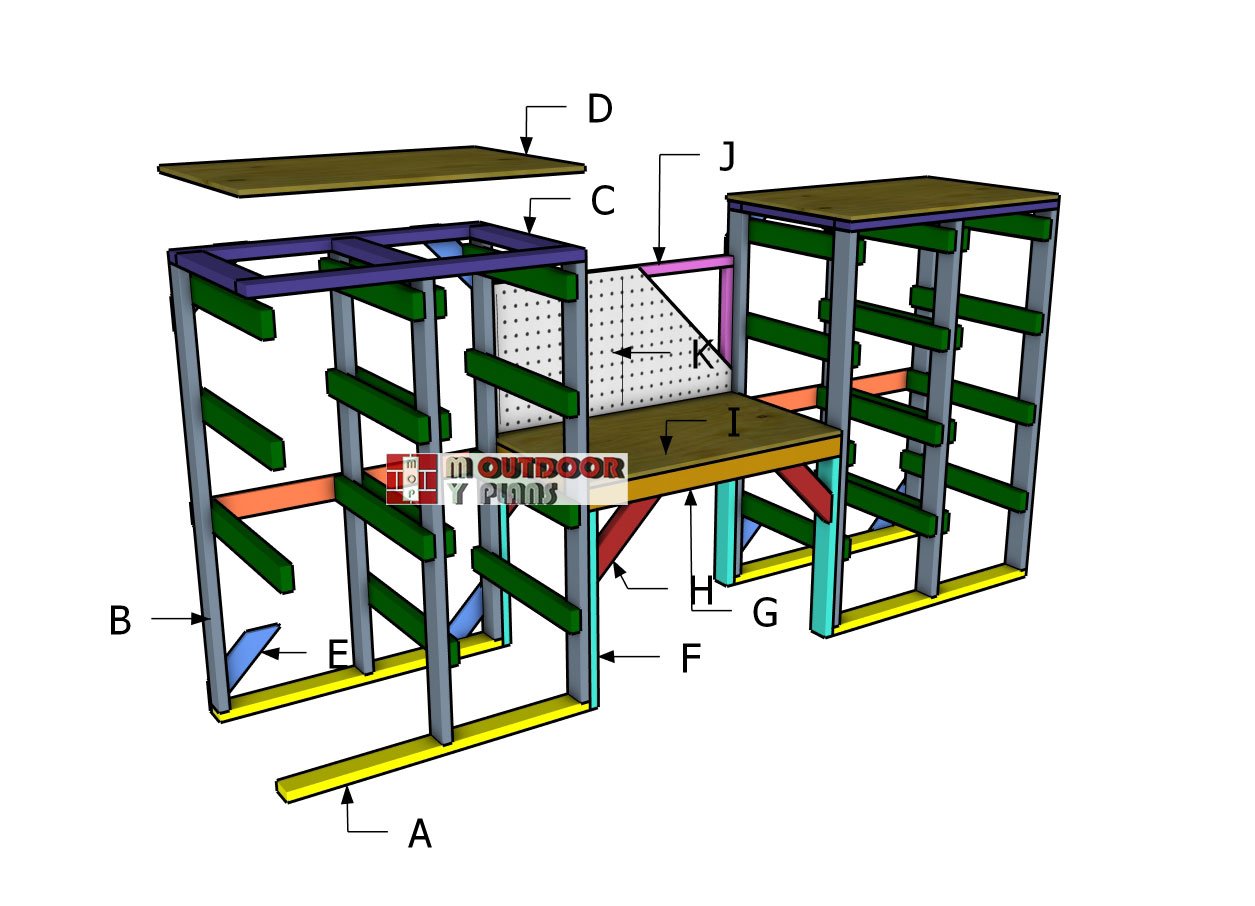

Building-a-storage-miter-saw-station

Cut and Shopping Lists

A – BASE – 2×4 lumber 47 1/2″ long – 4 pieces

B – UPRIGHTS – 2×4 lumber 66 1/2″ long – 12 pieces

C – TOP FRAME – 2×4 lumber 47 1/2″ long – 4 pieces

C – TOP FRAME – 2×4 lumber 23 1/2″ long – 6 pieces

D – TOP SHELVES – 2×4 lumber 31 1/4″x47 1/2″ long – 2 pieces

E – BRACES – 1×4 lumber 16″ long – 8 pieces

E – BRACES – 1×4 lumber 47 1/2″ long – 4 pieces

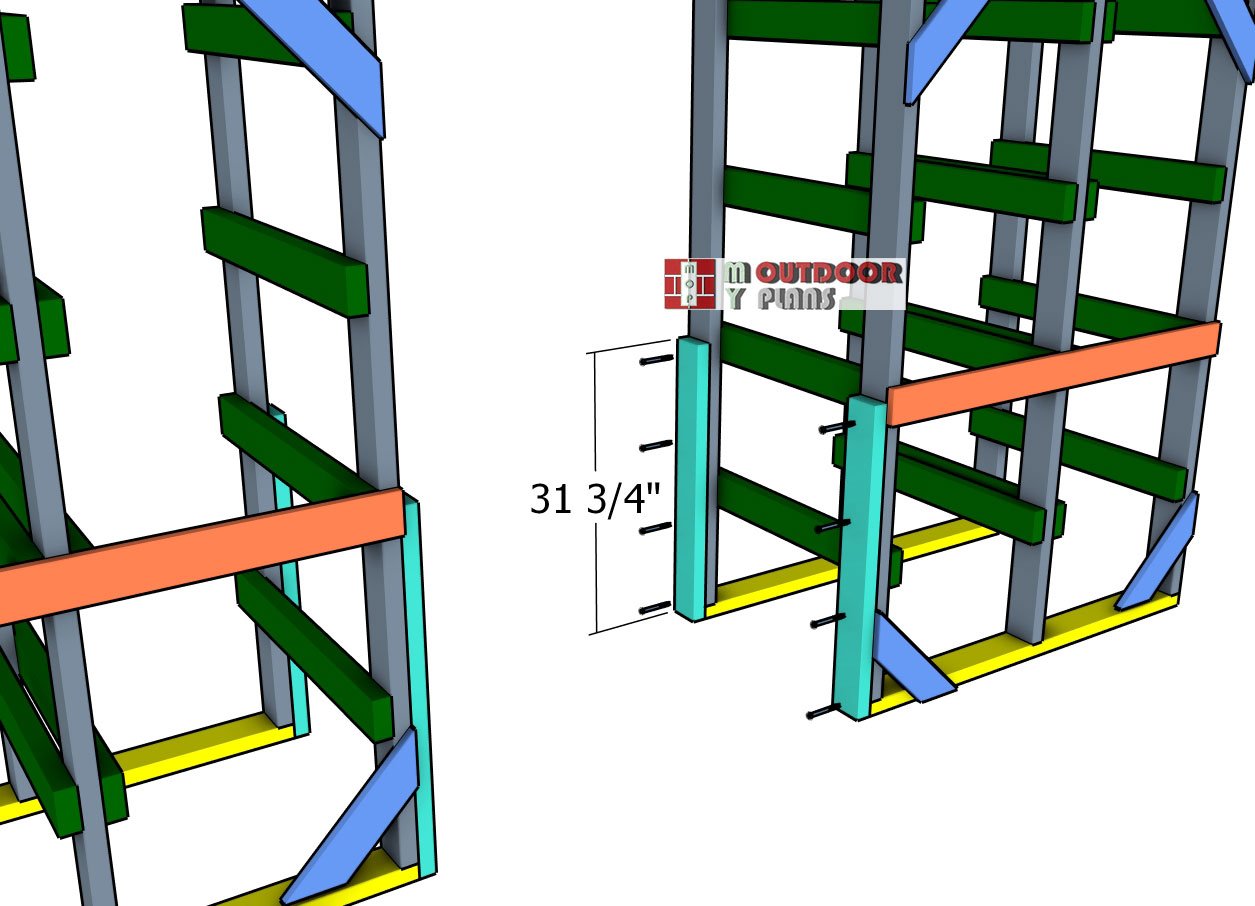

F – SUPPORTS – 2×4 lumber 31 3/4″ long – 4 pieces

G – TABLETOP FRAME – 2×4 lumber 48″ long – 2 pieces

G – TABLETOP FRAME – 2×4 lumber 27 1/2″ long – 3 pieces

H – BRACES – 2×4 lumber 16″ long – 4 pieces

I – TABLETOP – 3/4″ plywood 30 1/2″x48″ long – 4 pieces

J – BACK FRAME – 2×2 lumber 48″ long – 2 pieces

J – BACK FRAME – 2×2 lumber 21″ long – 3 pieces

J – BACK PANEL – pegboard 2’x4′ -1 piece

- 1×4 lumber 8 ft – 1 piece

- 1×4 lumber 10 ft – 1 piece

- 2×2 lumber 8 ft – 2 pieces

- 2×4 lumber 8 ft – 5 pieces

- 2×4 lumber 12 ft – 13 pieces

- pegboard 2’x4′ – 1 piece

- 3/4″ plywood 4’x8′ – 1 piece

- 2 1/2″ screws – 100 pieces

- 1 5/8″ screws – 100 pieces

- 27 gallon totes – 16 pieces

- stain / paint – 1 can

- glue – 1 bottle

Tools

![]() Hammer, Tape measure, Framing square, Level

Hammer, Tape measure, Framing square, Level

![]() Miter saw, Drill machinery, Screwdriver, Sander

Miter saw, Drill machinery, Screwdriver, Sander

![]() Safety Gloves, Safety Glasses, Pocket hole jig

Safety Gloves, Safety Glasses, Pocket hole jig

Time

Related

Pin it for Later!

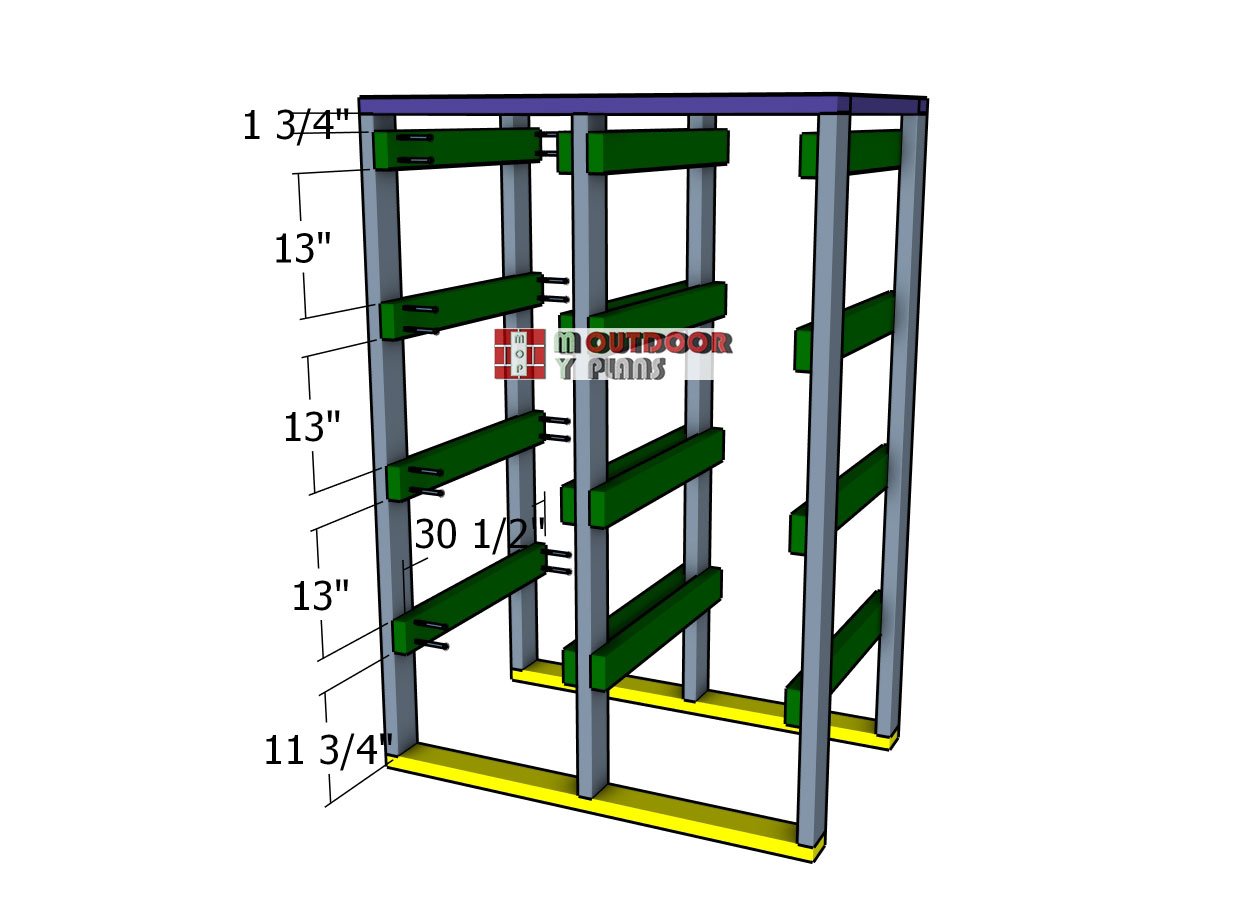

Step 1: Building the storage units

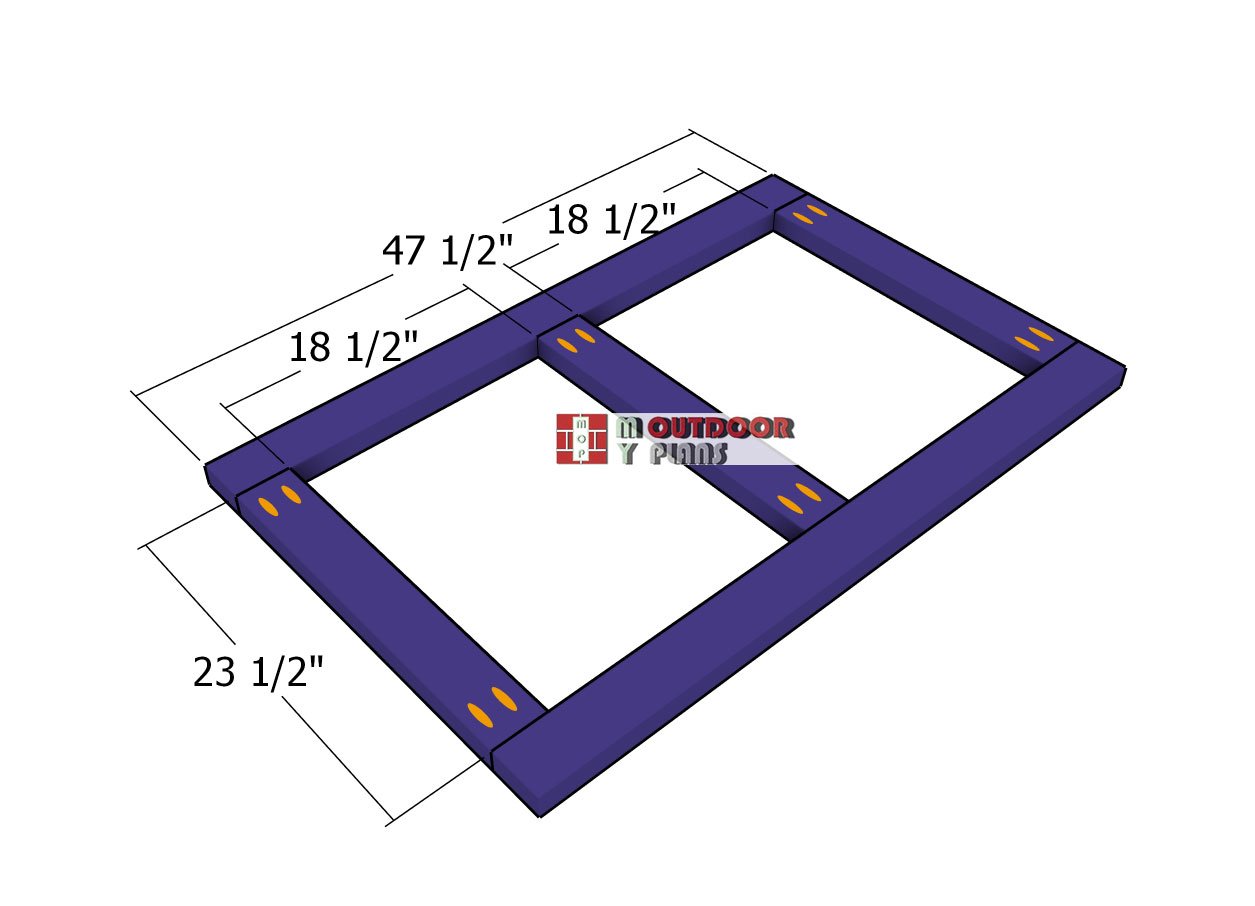

Top-frame-for-the-storage-units

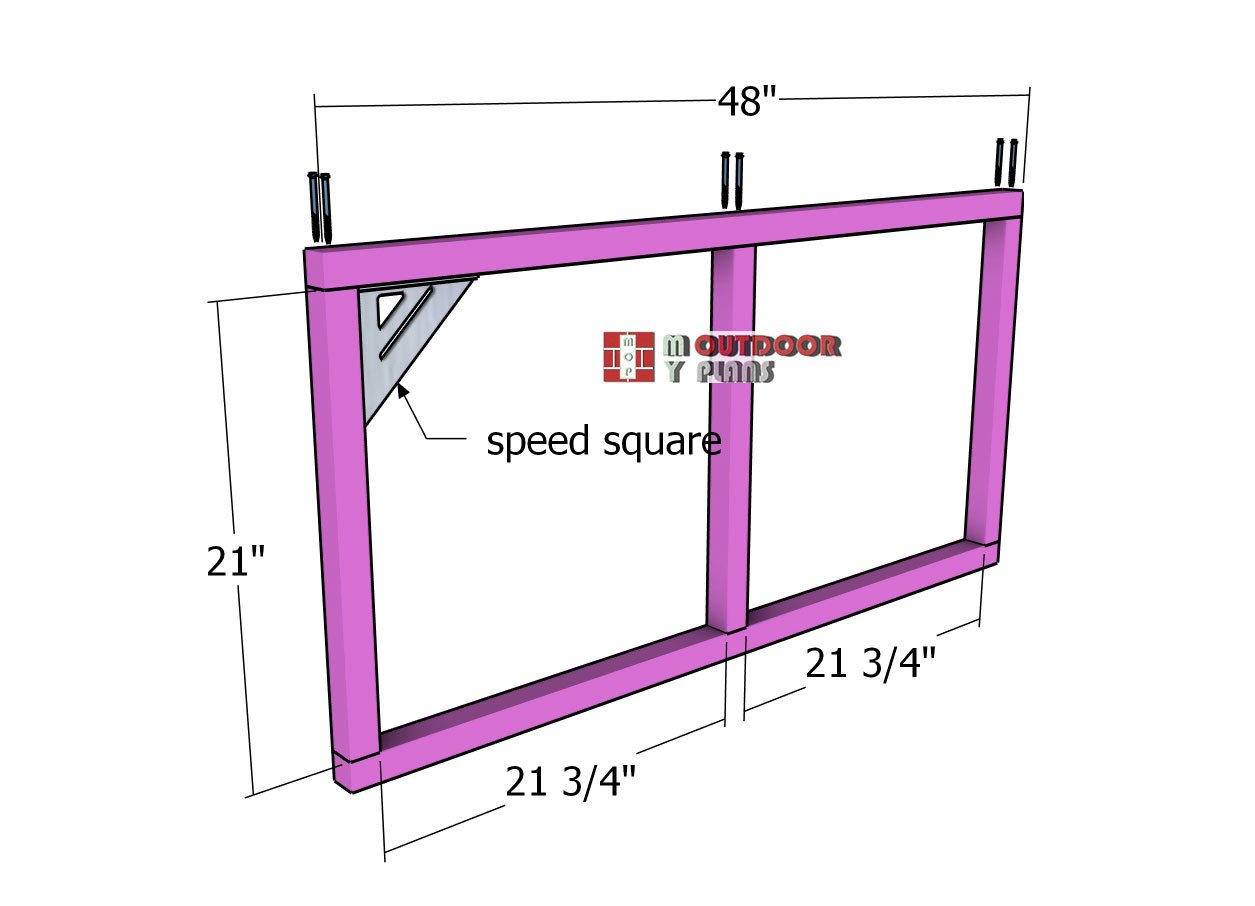

The first step in building the storage unit is constructing the top frame. Use 2×4 lumber for the components and drill pocket holes at both ends of the shorter boards. Lay the pieces out on a level surface, ensuring the edges are aligned and the corners are perfectly square.

Once everything is positioned correctly, assemble the frame by inserting 2 1/2″ screws into the pocket holes. Double-check for flush edges and square corners to ensure a sturdy and accurate foundation for the rest of the project.

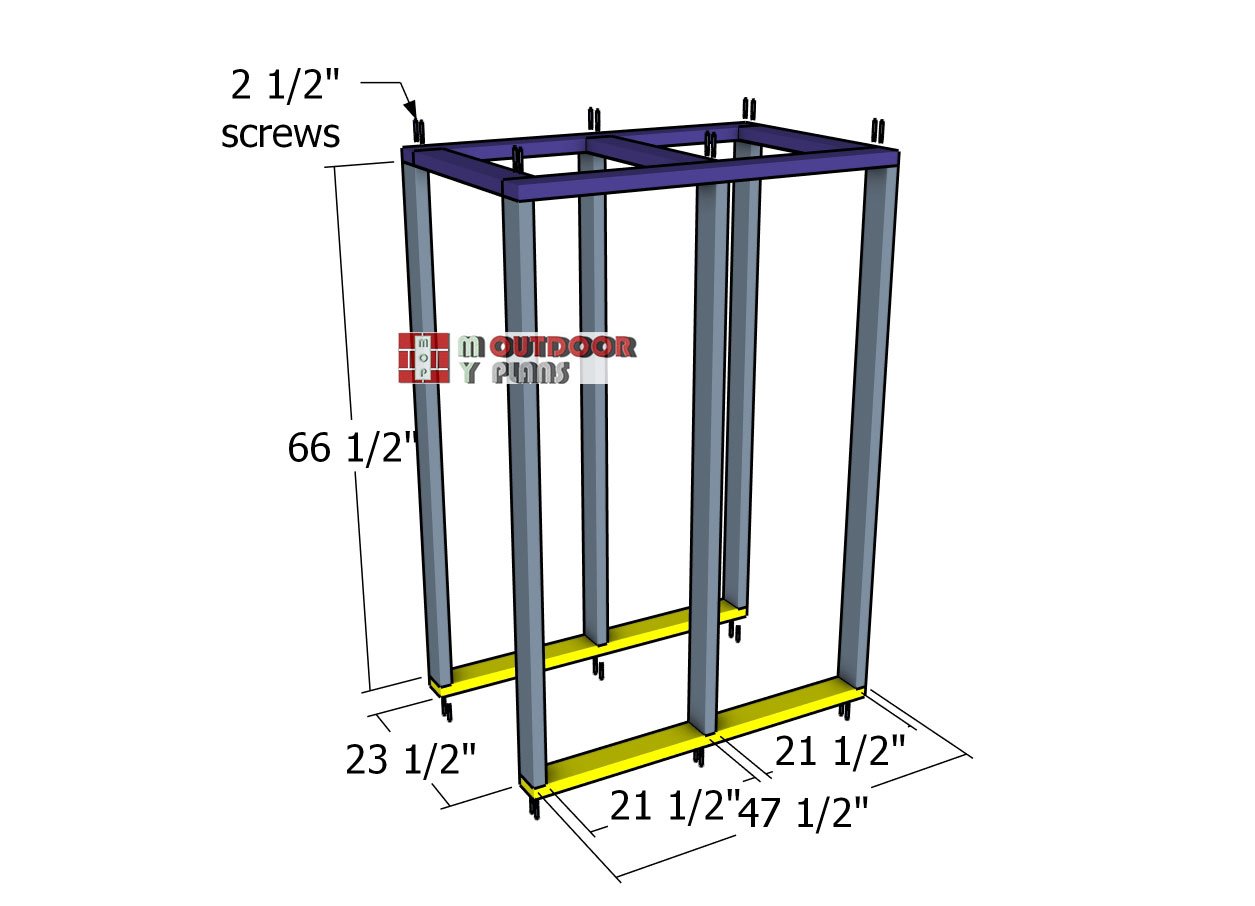

Assembling-the-tower-structure

Next, assemble the tower structure as shown in the diagram. Begin by attaching the upright boards to the top frame. Drill pilot holes to prevent splitting, then secure the uprights using 2 1/2″ screws. Align the edges carefully and ensure the corners are perfectly square for a sturdy and visually pleasing structure. Take your time with this step, as the tower’s stability depends on precise assembly.

Fitting-the-cleats

The next step in the storage project is attaching the 2×4 cleats to the tower structure. Position the cleats carefully, aligning them flush with the front edge of the tower. Drill pilot holes through the cleats to prevent splitting, then secure them to the uprights using 2 1/2″ screws. Use two screws for each joint to ensure a strong and stable connection. Double-check the alignment as you go to keep the structure neat and well-balanced.

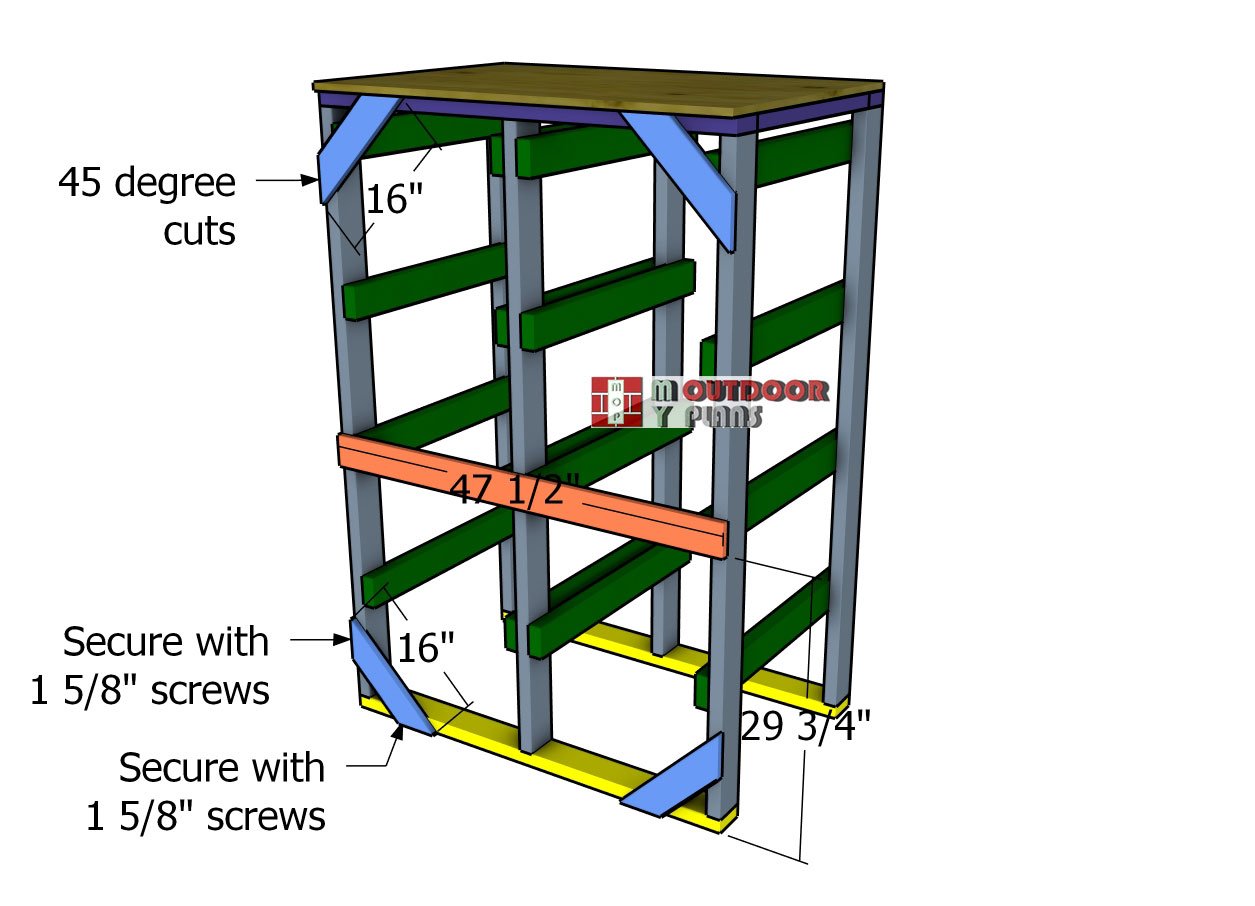

Braces-for-the-storage-units

With the tower unit fully assembled, it’s time to reinforce the structure by adding braces. Cut the braces from 2×4 lumber, making 45-degree cuts at both ends for a snug fit. Position the braces at the back of the unit to enhance stability and strength. Drill pilot holes at each connection point to prevent splitting, then secure the braces using 1 5/8″ screws. Ensure the braces are tightly fitted and aligned for a sturdy and professional finish.

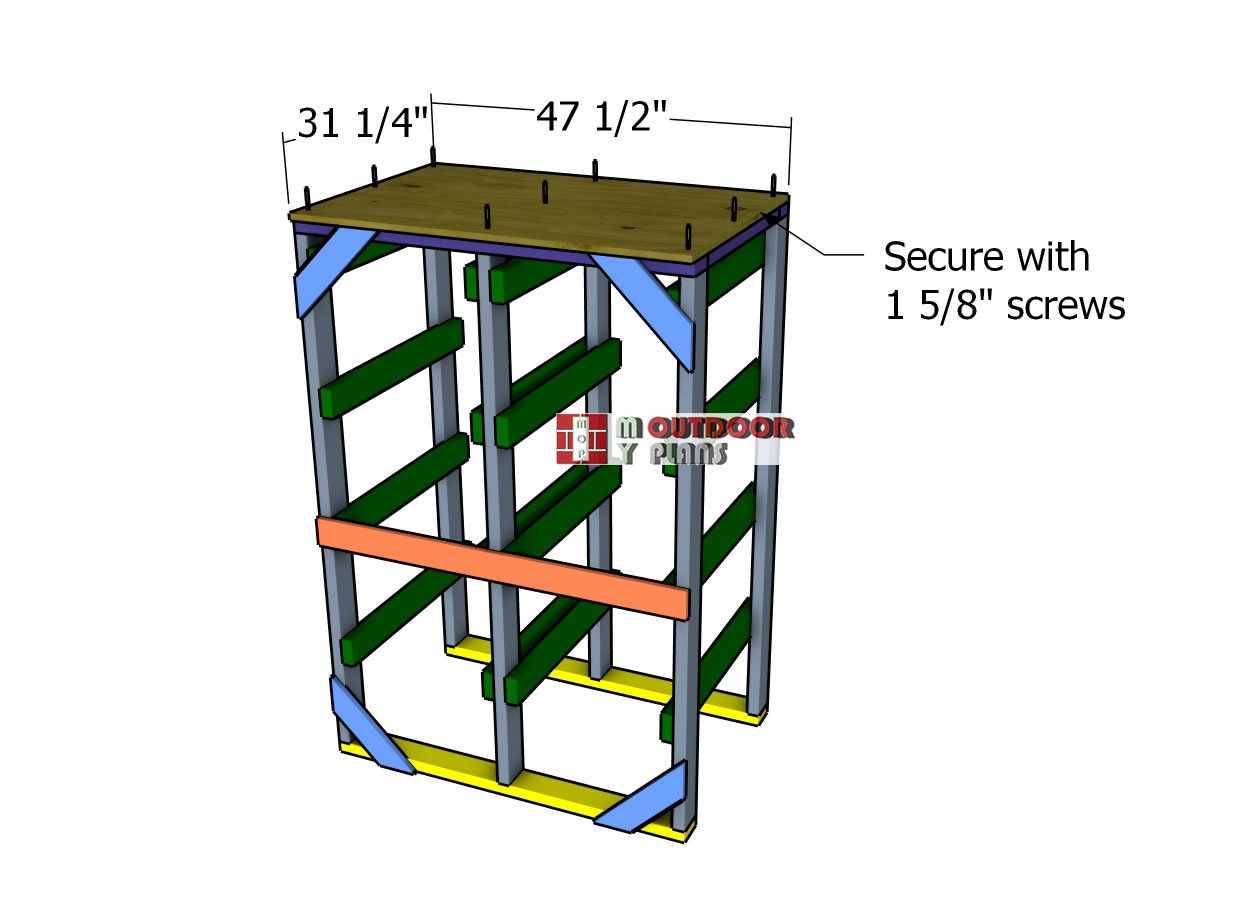

Top-shelf-for-the-storage-units

Attach the 3/4″ plywood panel to the top of the storage unit to create a sturdy and smooth surface. Align the edges of the panel flush with the frame for a clean, professional look. Drill pilot holes at regular intervals along the edges to prevent splitting, then secure the panel using 1 5/8″ screws. Tighten the screws evenly to ensure the panel is firmly attached and perfectly level.

Step 2: Assembling the structure

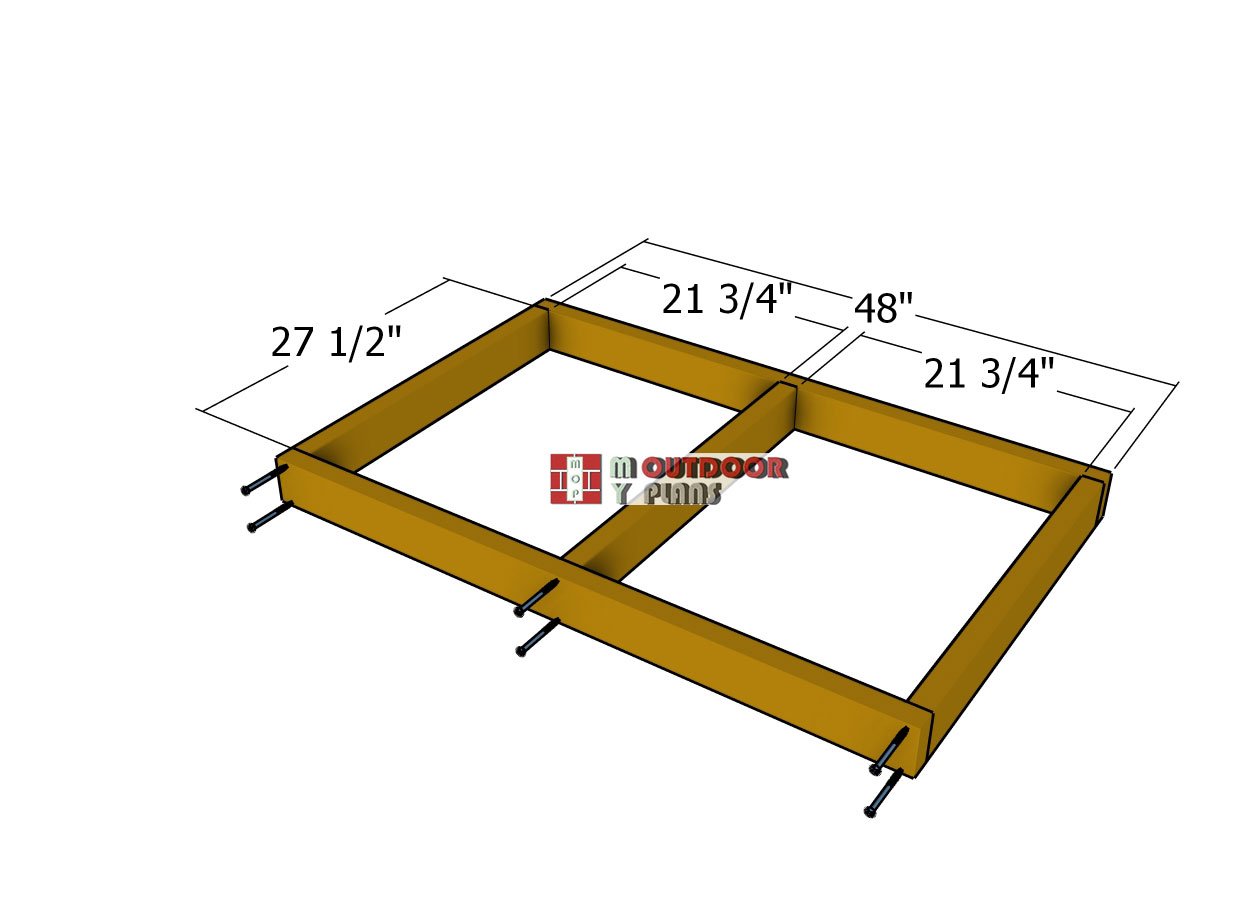

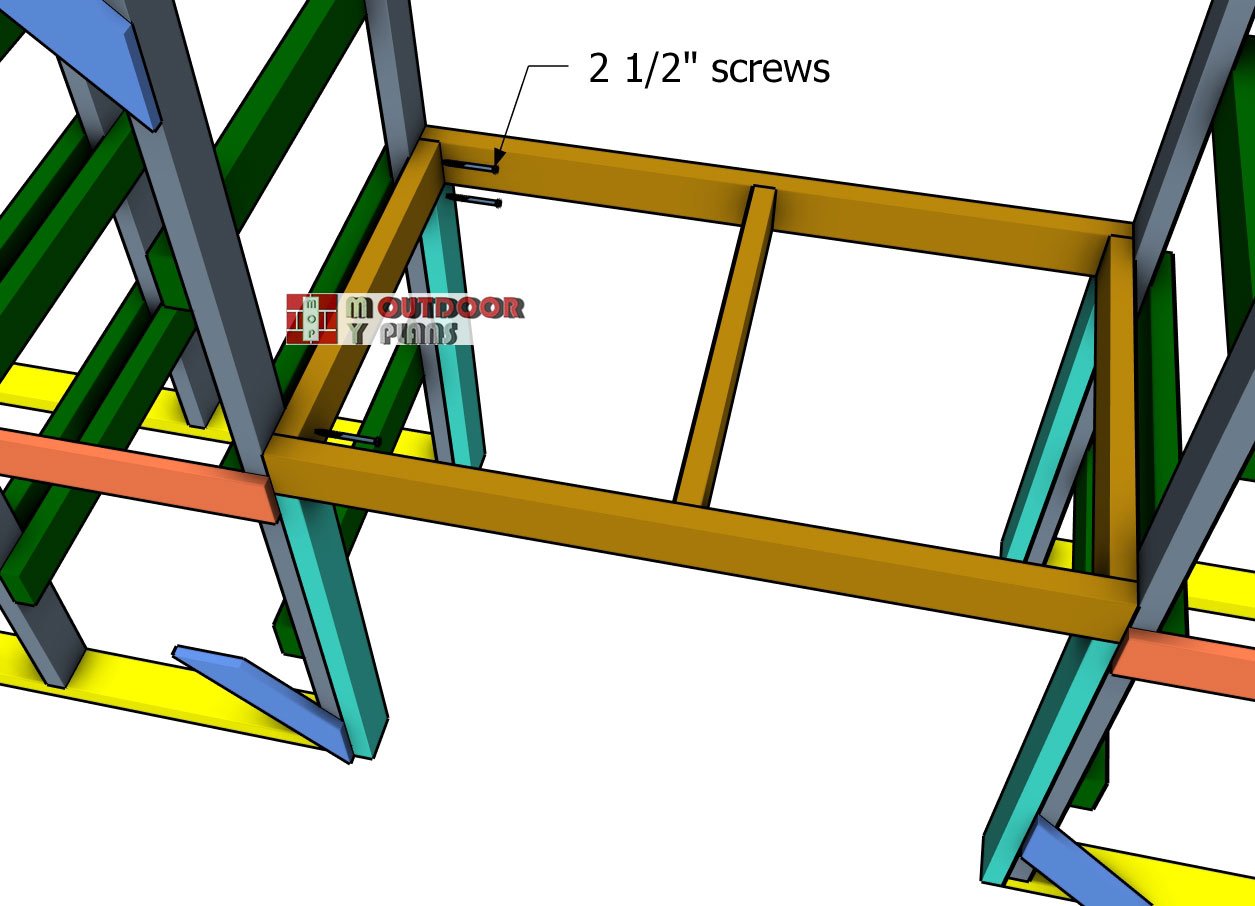

Tabletop-frame

With the two tote storage units completed, it’s time to build the miter saw station workbench. Start by cutting the frame components from 2×4 lumber according to the plan. Lay the pieces out on a level surface to ensure stability during assembly. Drill pilot holes through the 48″ long boards to prevent splitting, then attach them to the perpendicular components using 2 1/2″ screws. Take care to ensure the corners are square for a sturdy and accurate frame.

Tabletop-supports

Attach the 2×4 supports to the storage racks to provide a secure base for the tabletop. Position the supports carefully, ensuring they are level and properly aligned. Drill pilot holes at each connection point to prevent the wood from splitting, then fasten the supports using 2 1/2″ screws. Make sure the supports are firmly secured, as they will play a crucial role in keeping the tabletop stable and tight.

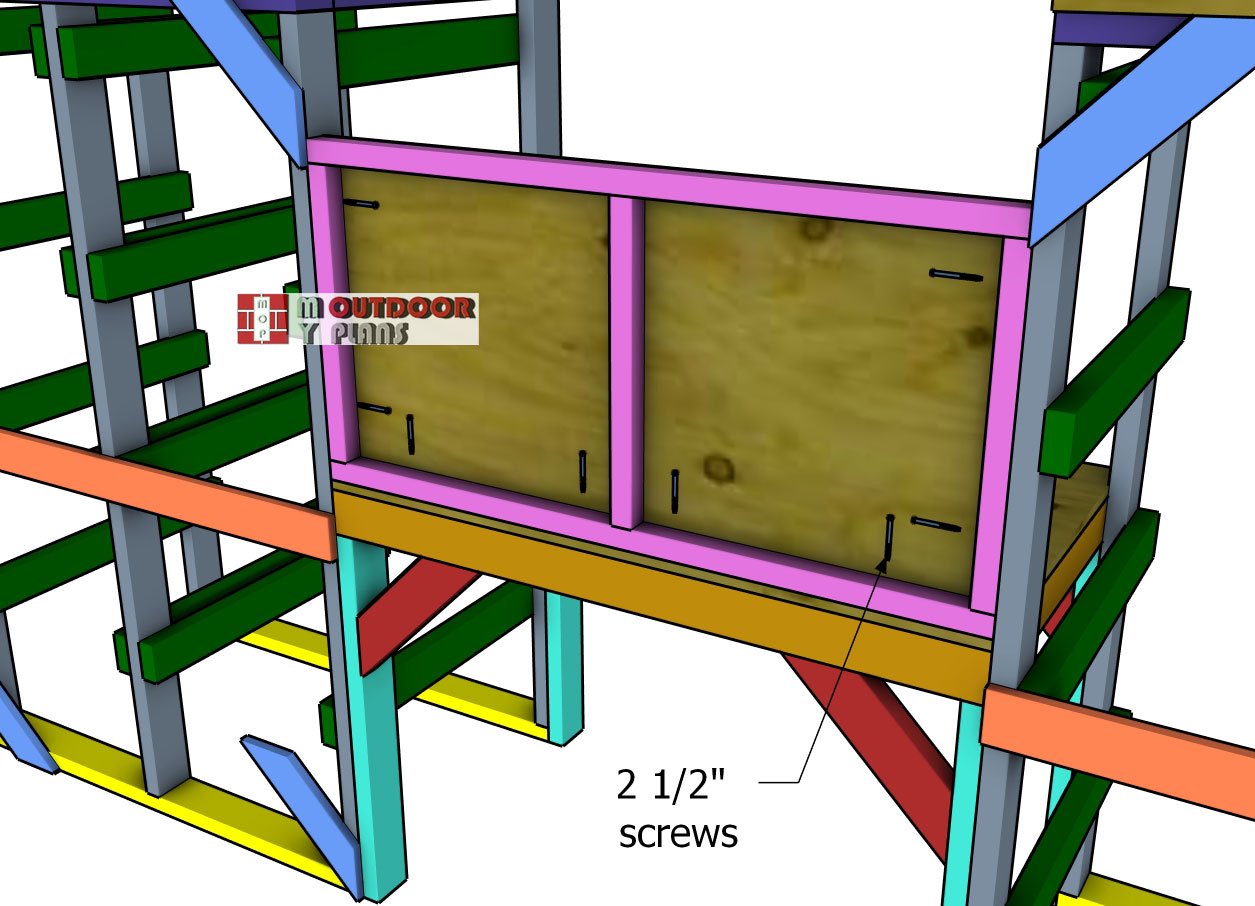

Attaching-the-frame-of-the-tabletop

Secure the frame to the two side racks using 2 1/2″ screws. Position the frame evenly across the racks, ensuring it is level and aligned properly. Drill pilot holes at each connection point to prevent splitting, then fasten the screws tightly to lock the frame into place. Double-check that everything is square and secure for a sturdy and professional finish.

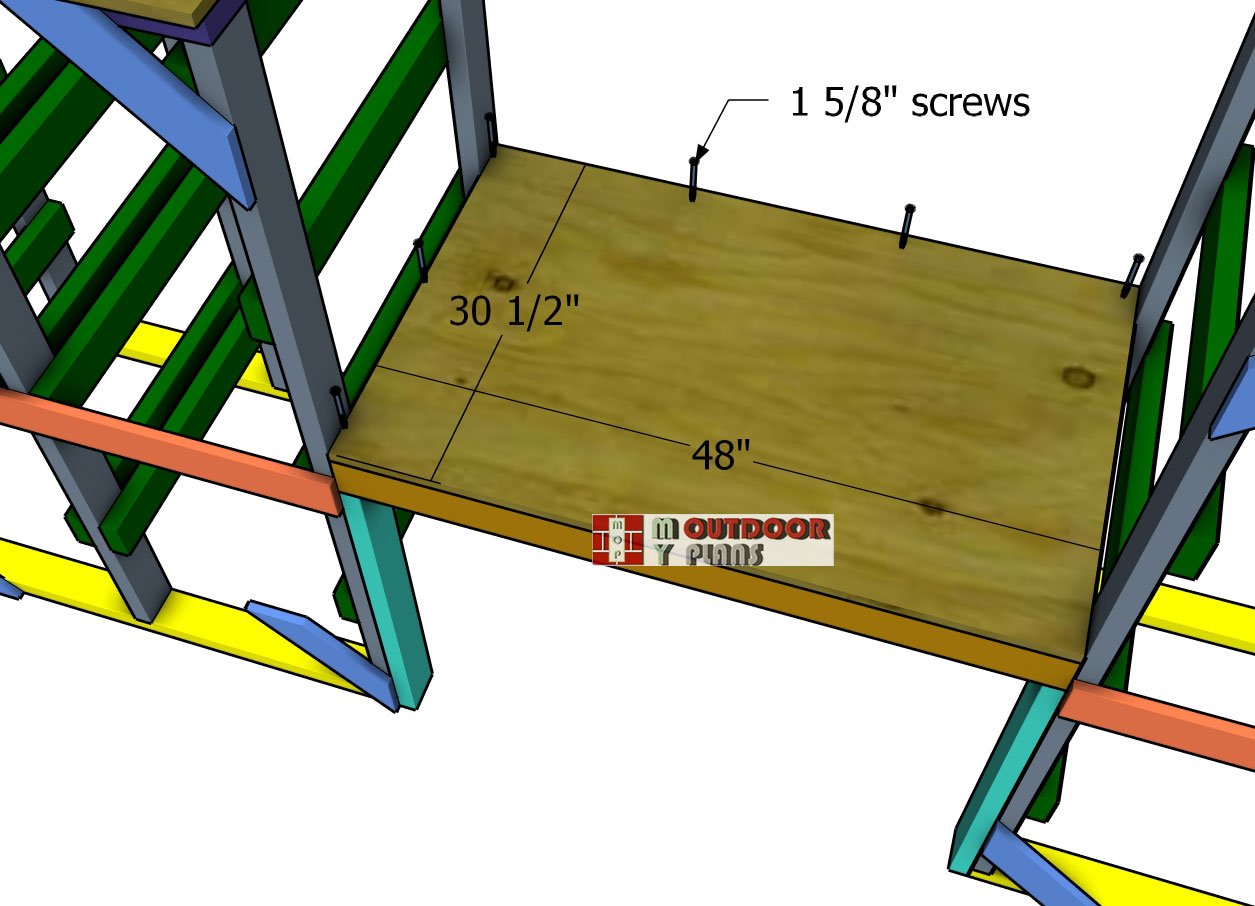

Attaching-the-workbench-top

Attach the 3/4″ plywood panel to the workbench to create a durable and smooth work surface. Carefully align the edges flush with the frame for a clean, professional look. Drill pilot holes at regular intervals along the edges and secure the panel using 1 5/8″ screws. Tighten the screws evenly to ensure the panel is firmly attached and perfectly level, providing a sturdy foundation for your miter saw station.

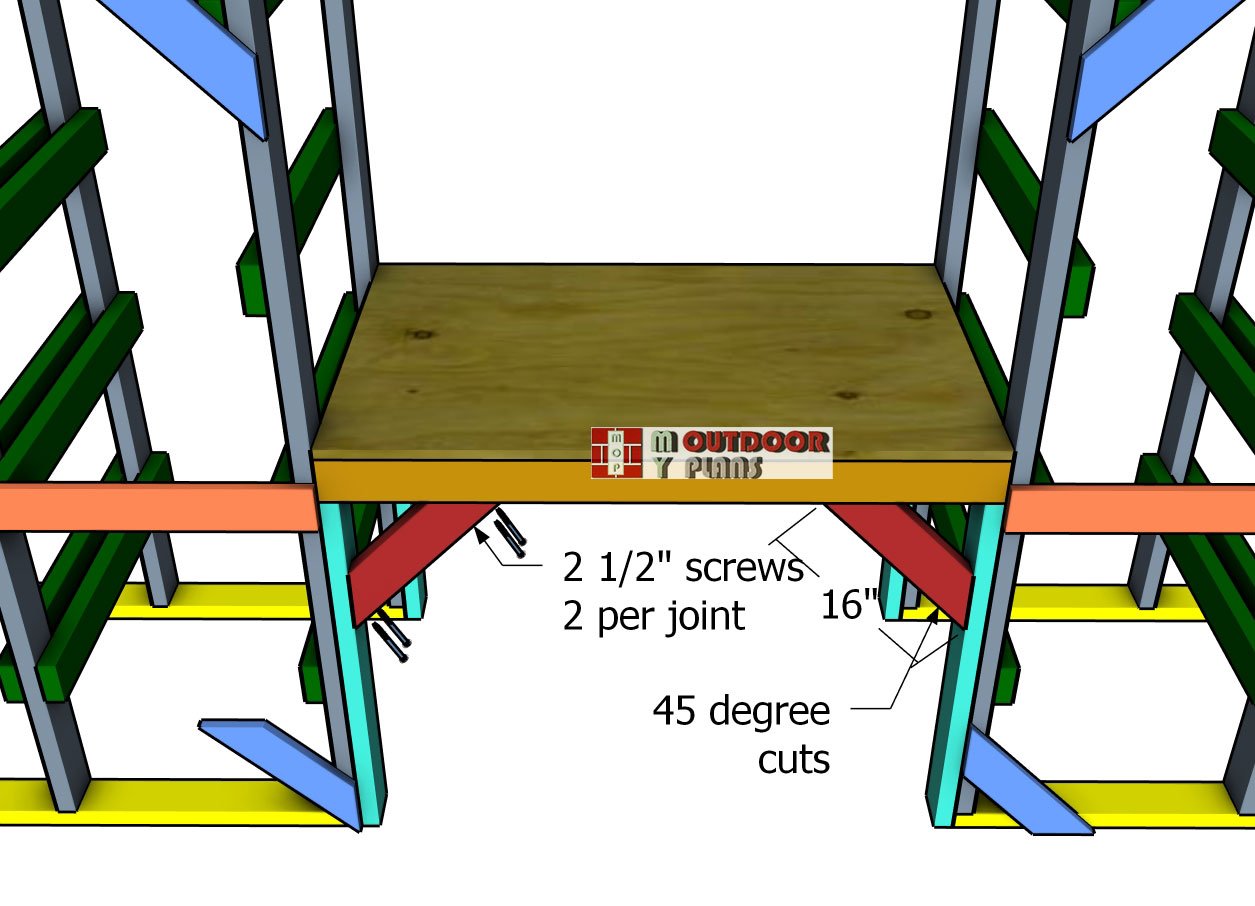

Braces-for-the-workbench-station

Use 2×4 lumber to craft the diagonal braces for added stability. Cut both ends of each brace at a 45-degree angle to ensure a snug fit. Position the braces diagonally on the workbench frame as shown in the plans. Drill pilot holes to prevent splitting, then secure the braces in place using 2 1/2″ screws. These braces will significantly enhance the rigidity of the assembly, ensuring a strong and durable structure.

Frame-for-pegboard

To take your workbench to the next level, we’ll add a pegboard to the back for extra functionality and organization. Begin by building a small frame for the pegboard using 2×2 lumber. Cut the components to the required dimensions and lay them out on a level surface. Drill pilot holes to prevent splitting, then assemble the frame using 2 1/2″ screws. Ensure the corners are square and the edges align flush for a sturdy and well-fitted frame.

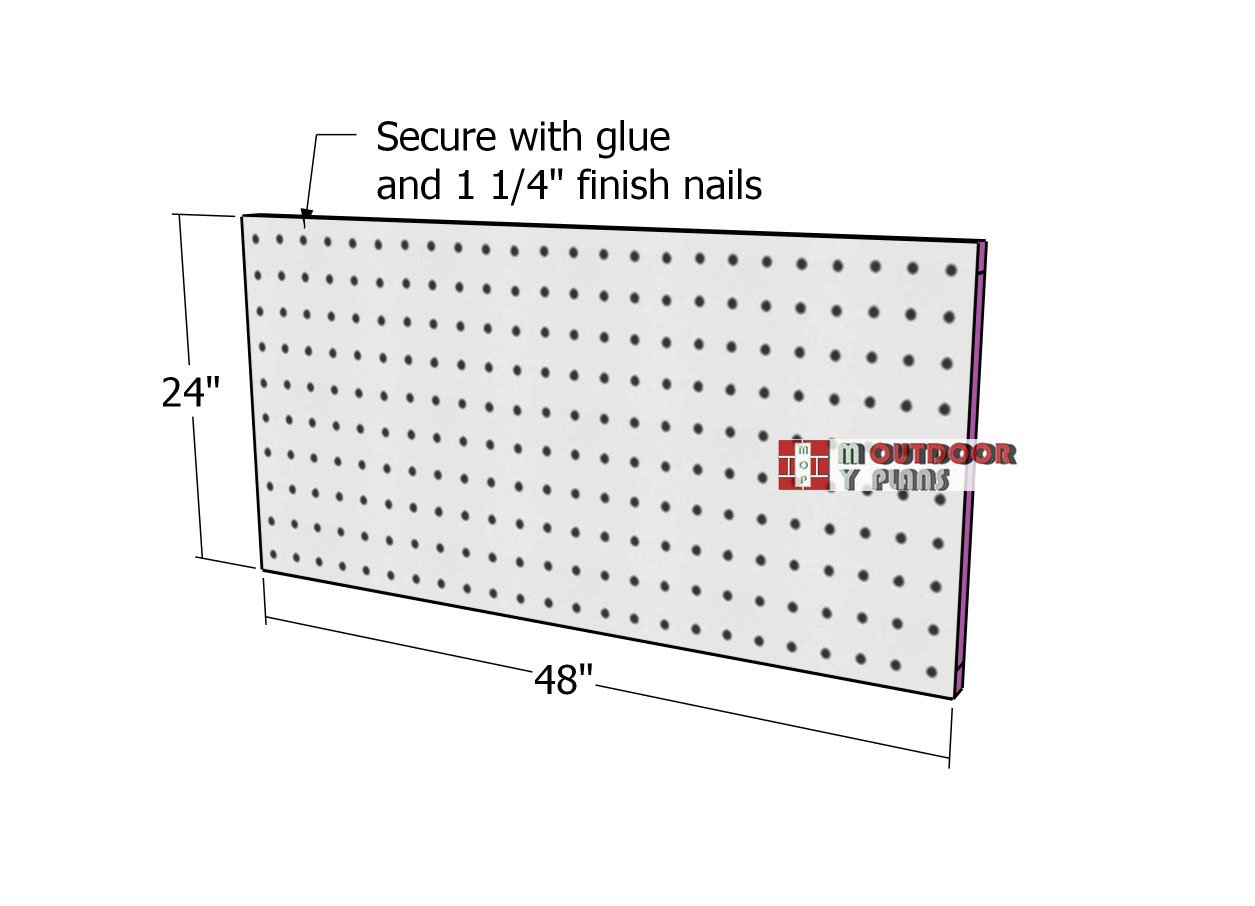

Fitting-the-pegboard-panel

Attach the 2’x4′ pegboard to the frame for a functional and organized storage solution. Align the edges of the pegboard flush with the frame to ensure a clean fit. Drill pilot holes every 12″ along the frame to prevent splitting, then secure the pegboard in place using 1 5/8″ screws. Tighten the screws evenly for a firm attachment, creating a sturdy and reliable backdrop for your tools.

Fitting-the-pegboard-frame-into-place

Attach the pegboard frame to the miter saw station, as shown in the diagram. Carefully align the edges to ensure a neat and balanced fit. Drill pilot holes through the frame into the station to prevent splitting, then secure it with 2 1/2″ screws. Tighten the screws evenly to lock the pegboard firmly into place, providing a sturdy and functional addition to your workspace.

Step 3: Finishing Touches

Sliding-the-totes-in

With the assembly complete, it’s time to focus on the finishing touches to bring your project to life. Start by filling any visible screw holes or gaps with wood putty for a clean and polished appearance. Once the putty is dry, sand all surfaces thoroughly, paying close attention to the edges and corners, to achieve a smooth, splinter-free finish.

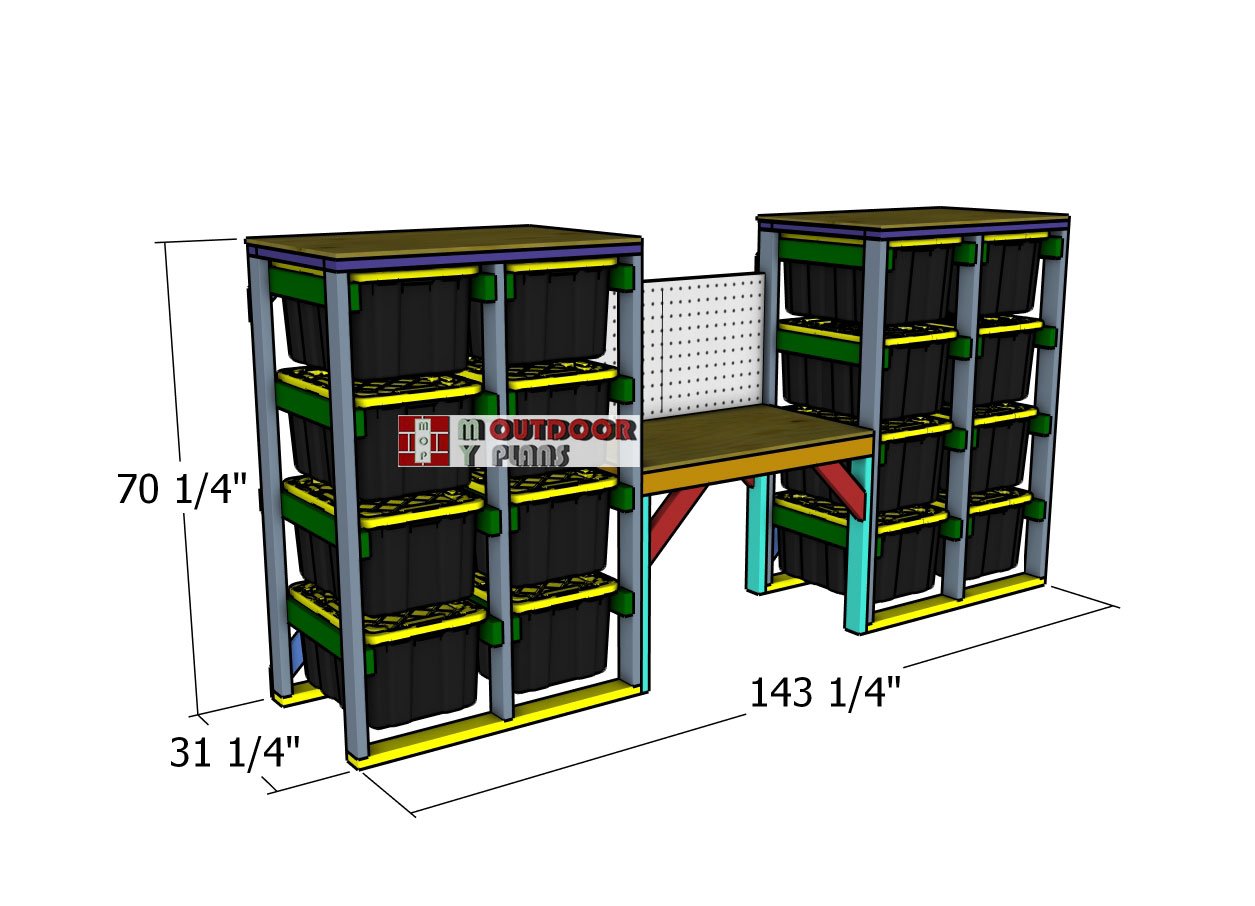

Tote-storage-miter-saw-station—dimensions

For added durability and style, apply a coat of paint or wood stain to match your workspace’s aesthetic. If you want to preserve the natural wood look, consider using a clear polyurethane or water-based finish for protection. Finally, organize your tools and supplies on the pegboard and shelves, transforming your miter saw station into a fully functional and visually appealing centerpiece for your workshop.

How to make a storage miter saw station

Designed to hold up to 16 standard 27-gallon totes, it provides ample room for organizing tools, materials, and supplies all in one place. Whether you’re storing seasonal decorations, workshop essentials, or larger items, the generous storage capacity keeps everything neatly tucked away while still easily accessible. This feature maximizes the functionality of your station, turning it into a central hub of organization and efficiency for your workshop or garage.

DIY Miter Saw Station with storage totes

If you want to get the Premium plans with all the extras, just press the GET PREMIUM PLANS button bellow. If you want to get the free plans, just read the blog FAQs. Make sure you check out the rest of the DIY plans on my blog, for even more building inspiration.

This woodworking project was about tote storage workbench – free DIY plans. If you want to see more outdoor plans, check out the rest of our step by step projects and follow the instructions to obtain a professional result.

2 comments

Why would you put your Miter so low you can’t use it?

The tabletop is set at 36″ high, which is considered the ideal height for a miter saw station, offering comfort and efficiency during use. However, if you have specific preferences or requirements, feel free to adjust the height to suit your needs. These plans are flexible, so you can customize the design to make it perfect for your workspace!