This step by step diy woodworking project is about 2×4 6 ft workbench plans. I have designed this basic 6 ft workbench, so you can organize your show and build projects with ease. This workbench features a low shelf. Moreover the frame of the bench is built entirely from 2x4s, so you can find the materials very easily. Take a look over the rest of our woodworking plans, if you want to get more building inspiration.

When buying the lumber, you should select the planks with great care, making sure they are straight and without any visible flaws (cracks, knots, twists, decay). Investing in cedar or other weather resistant lumber is a good idea, as it will pay off on the long run. Use a spirit level to plumb and align the components, before inserting the galvanized screws, otherwise the project won’t have a symmetrical look. If you have all the materials and tools required for the project, you could get the job done in about a day. See all my Premium Plans HERE.

Projects made from these plans

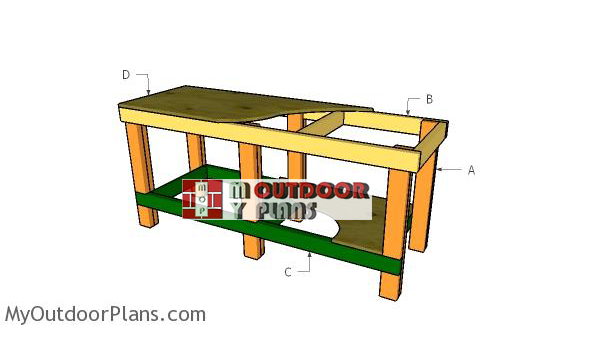

2×4 6 ft Workbench Plans

Building-a-6-ft-workbench

Cut & Shopping Lists

- A – 6 pieces of 2×4 lumber – 31 1/4″ long, 6 pieces – 18 1/4″ long, 6 pieces – 6″ long LEGS

- B – 2 pieces of 2×4 lumber – 72″ long, 4 pieces – 21″ long FRAME

- C – 2 pieces of 2×4 lumber – 69″ long, 4 pieces – 21″ long FRAME

- D – 1 piece of 3/4″ plywood – 24″x72″ long, 1 piece – 24″x62″ long TOPS

- 9 pieces of 2×4 lumber – 8′

- 1 piece of 3/4″ plywood – 4’x8′

- 2 1/2″ screws

- 2″ nails

- 1 5/8″ screws

- wood glue, stain/paint

- vise

- caster wheels

Tools

![]() Hammer, Tape measure, Framing square, Level

Hammer, Tape measure, Framing square, Level

![]() Miter saw, Drill machinery, Screwdriver, Sander

Miter saw, Drill machinery, Screwdriver, Sander

Time

Related

Building a 8 ft workbench from 2x4s

Building-the-top-frame

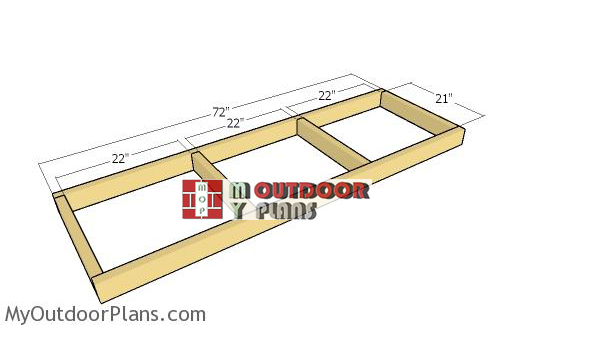

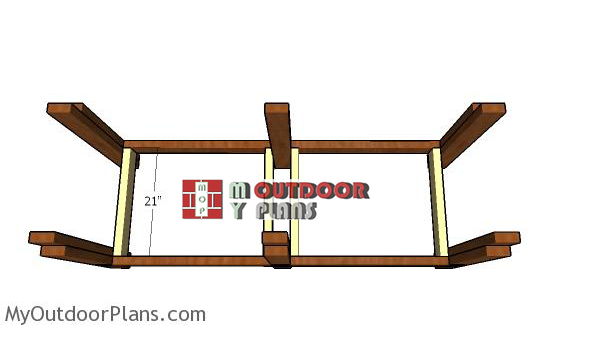

The first step of the 2×4 workbench project is to build the top frame. Cut the components from 2×4 lumber, as shown in the diagram. Drill pilot holes through the 96″ long beams and insert 2 1/2″ screws into the perpendicular components. Make sure the edges are flush and the corners are square. It is important to assemble the frame on a level surface, otherwise it might end up warped.

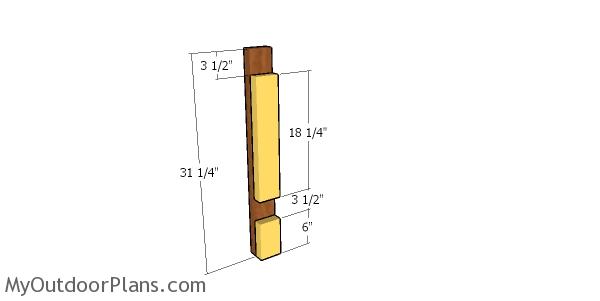

Building the legs

Next, build the legs for the workbench from 2x4s. Cut the components from 2×4 lumber at the dimensions shown in the plans. Drill pilot holes through the yellow components and insert 2 1/2″ screws into the legs. Add glue to the joints and align the edges flush. Fit a scrap piece of 3 1/2″ lumber between the yellow components, so you make sure the braces will fit properly.

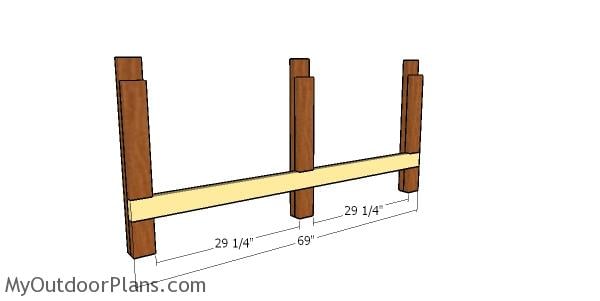

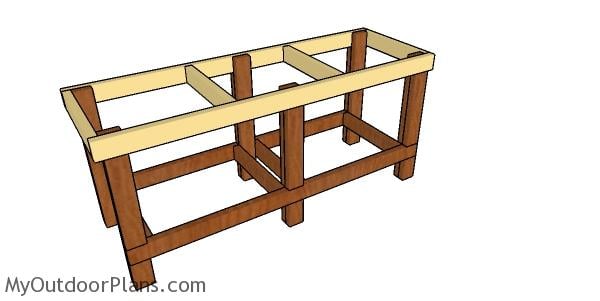

Fitting the front and back bottom supports

Fit the braces to the legs, as shown in the plans. Drill pilot holes, add glue to the joints and insert 2 1/2″ screws. Check if the corners are square prior to inserting the screws.

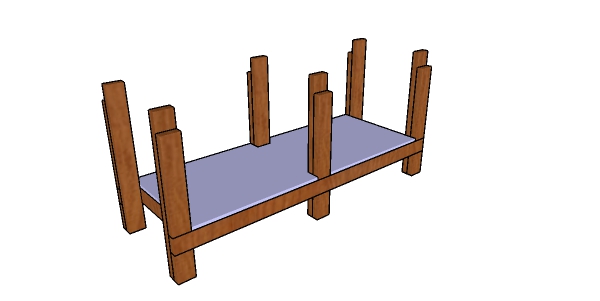

Assembling-the-lower-frame-worktable

Next, attach the 2×4 supports to the base shelf frame. Drill pilot holes through the braces and insert 2 1/2/” screws into the supports. Check if the corners are right-angled with a carpentry square.

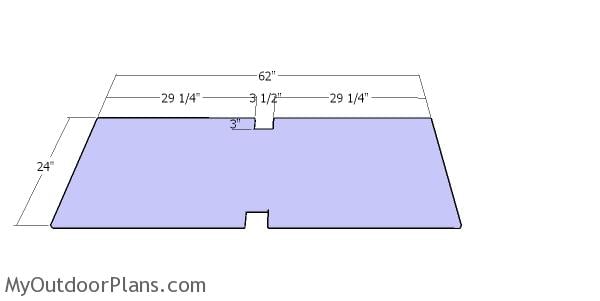

Building the bottom shelf

Continue the project by cutting the lower shelf. Mark the cut lines on the 3/4″ plywood and then cut the notches with a saw.

Fitting the lower shelf

Fit the panel to the frame of the workbench and lock them into place with 1 5/8″ screws. Align the edges with attention for a professional result. Insert the screws every 8″ along the framing.

Fitting the top frame

Afterwards, you need to assemble the workbench together by attaching the top frame. Use a carpentry square to make sure the corners are right-angled. Drill pilot holes through the legs and insert 2 1/2″ screws into the top frame.

Fitting the tabletop

Cut and fit the 3/4″ plywood sheet to the top of the workbench. Align the edges and lock it into place with nails or screws.

2×4 6 ft Workbench Plans

Last but not least, you need to take care of the finishing touches. Therefore, fill the holes and sand the surface with 120-220 grit sandpaper. Apply a few coats of stain or paint to enhance the look of the workbench.

6 ft Workbench Plans

Add a vise or other features to the workbench, such as a power outlet or hooks to keep the power tools organized. You can add caster wheels to the legs, so you can move the workbench from one location to another really quickly.

Top Tip: Apply a few coats of paint or stain to the components, to enhance the look of the project.

This woodworking project was about 6 ft workbench plans free. If you want to see more outdoor plans, check out the rest of our step by step projects and follow the instructions to obtain a professional result. 1/4