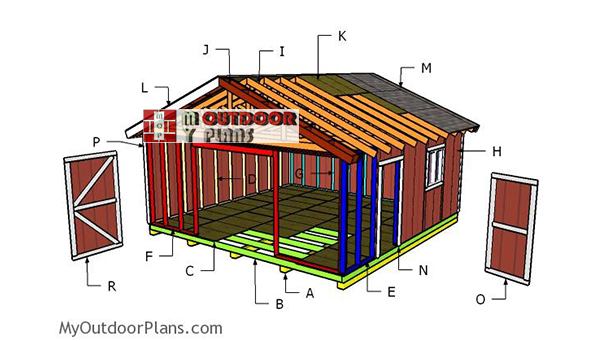

This step by step diy project is about 20×20 wood shed plans. I have designed this large storage shed with a gable roof so you can create more space for your tools and outdoor furniture. This shed features large 8′ double doors, a side door and a side window. However, make sure you read the local building codes before starting the project. Take a look over the rest of my woodworking plans, if you want to get more building inspiration. Premium Plans for this project available in the Shop.

All my woodworking plans come with 3D diagrams and step by step instructions, so you can build the project from scratch. In addition, the free plans come with a full Cut / Shopping list.

When buying the lumber, you should select the planks with great care, making sure they are straight and without any visible flaws (cracks, knots, twists, decay). Investing in cedar or other weather resistant lumber is a good idea, as it will pay off on the long run. Use a spirit level to plumb and align the components, before inserting the galvanized screws, otherwise the project won’t have a symmetrical look. If you have all the materials and tools required for the project, you could get the job done in about a day. See all my Premium Plans HERE.

Projects made from these plans

20×20 Shed Plans – How to build a 20×20 shed

Building-a-20×20-gable-shed

Cut + Materials Lists

- A – 5 pieces of 6×6 lumber – 240″ long SKIDS

- B – 2 pieces of 2×6 lumber – 240″ long, 11 pieces – 237″ long FLOOR FRAME

- C – 10 pieces of 3/4″ plywood – 48″x96″ long, 5 pieces – 48″x48″ long FLOOR

- D – 2 pieces of 2×4 lumber – 240″ long, 1 piece – 233″ long, 13 pieces – 91 1/2″ long SIDE WALL

- E – 1 piece of 2×4 lumber – 240″ long, 1 piece – 233″ long, 1 piece – 54″ long, 1 piece – 150″ long, 16 pieces – 91 1/2″ long, 2 pieces – 78 1/2″ long, 6 pieces – 7 1/2″ long, 2 pieces – 36″ long, 3 pieces – 37″ long, 6 pieces of 2×6 lumber – 39″ long SIDE WALL

- F – 2 pieces of 2×4 lumber – 68 1/2″ long, 1 piece – 233″ long, 1 piece – 240″ long, 8 pieces – 91 1/2″ long, 2 pieces – 89″ long, 2 pieces of 2×6 lumber – 99″ long FRONT WALL

- G – 2 pieces of 2×4 lumber – 233″ long, 1 piece – 240″ long, 11 pieces – 91 1/2″ long BACK WALL

- H – 19 pieces of T1-11 siding – 48″x96″ long, 1 piece – 8 1/2″x48″ long SIDING

- 5 pieces of 6×6 lumber – 20′

- 13 pieces of 2×6 lumber – 20′

- 13 pieces of 3/4″ plywood – 4’x8′

- 11 pieces of 2×4 lumber – 20′

- 54 pieces of 2×4 lumber – 8′

- 2 pieces of 2×6 lumber – 10′

- 3 pieces of 2×6 lumber – 8′

- 1 piece of 1/2″ plywood – 4’x8′

- 19 pieces of T1-11 siding – 4’x8′

- 2 1/2″ screws, 3 1/2″ screws, 1 5/8″ screws

- 6d nails, 16d nails

- wood filler , wood glue, stain/paint

Tools

![]() Hammer, Tape measure, Framing square, Level

Hammer, Tape measure, Framing square, Level

![]() Miter saw, Drill machinery, Screwdriver, Sander

Miter saw, Drill machinery, Screwdriver, Sander

Time

Related

- PART 1: 20×20 Shed Plans

- PART 2: 20x20 Shed Roof Plans

- PART 3: 20×20 Shed Door and Trims Plans

- 20×24 gable shed plans

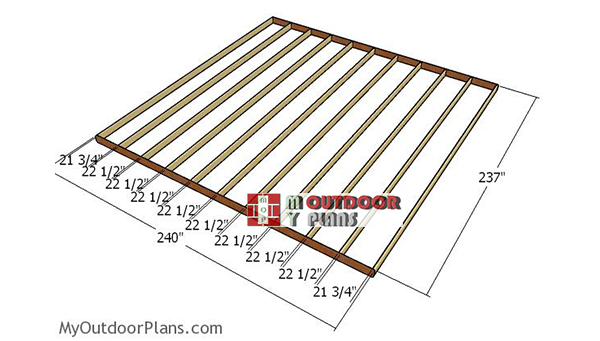

Step 1: How to build the floor frame

Building-the-floor-frame

The first step of the project is to frame the floor for the 20×20 storage shed. Therefore, use 2×6 or 2×8 lumber for the joists and cut them at the dimensions shown in the diagram. Drill pilot holes through the rim joists and insert 3 1/2″ screws into the perpendicular components.

Nwxt, place the joists every 24″ on center. Alternatively, you can fit the joists every 16″ on center, as well. Align the edges flush and make sure the corners are square.

Fitting the skids

Select the location for the shed to suit your needs and making sure it complies with the local building codes. Next, level the surface with attention and then compact a thick layer of gravel. Fit the 6×6 skids and then attach the floor frame. Also, align the edges flush and use rafter ties to lock them together tightly.

If the local codes don’t allow you to use 6×6 skids, you might have to pour footings.

Floor sheets

The next step of the project is to lay the 3/4″ plywood sheets to the floor of the shed. Align the edges flush and leave no gaps between the sheets for a professional result. Insert 1 5/8″ screws, every 8″ along the joists, for a professional result. Follow the pattern shown in the diagram for a neat result.

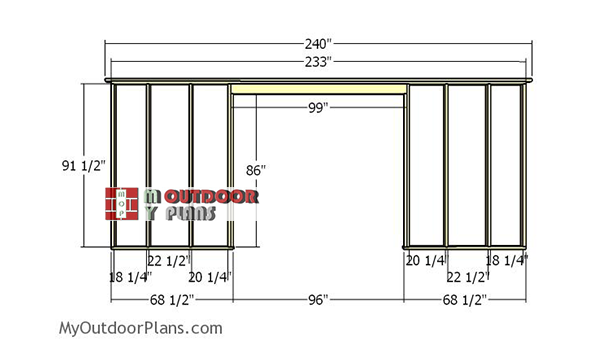

Step 2: How to build the wall frames

Building-the-front-wall-frame

Build the front wall from for the 20×20 gable shed from 2×4 lumber. Additionally, cut the plates and the studs from 2×4 lumber at the proper sizes, as shown in the diagram. Use 2×6 lumber and 1/2″ plywood for the double header (sandwich the plywood between the beams with 2 1/2″ screws inserted through both sides). Fit the header to the wall frame and lock it into place with nails.

Next, drill pilot holes through the plates and insert 3 1/2″ screws into the studs. Place the studs every 24″ on center for a professional result. Align the edges flush and make sure the corners are square. You can adjust the size of the door opening to suit your needs.

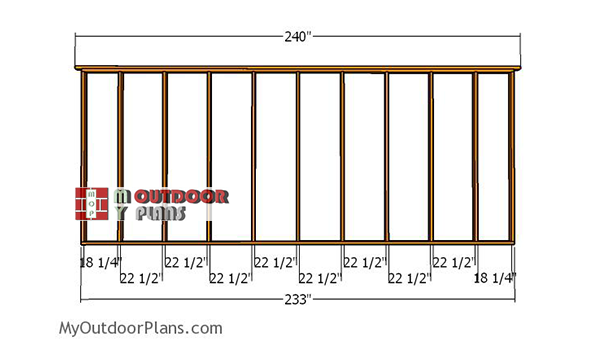

Back-wall-frame

Next, frame the back wall for the 20×20 shed. Drill pilot holes through the plates and insert 3 1/2″ screws into the studs. Place the studs every 24″ on center and make sure the edges are flush.

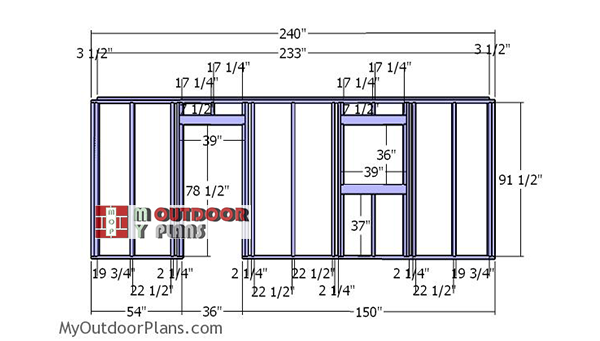

Building-the-side-wall-with-frame-and-door

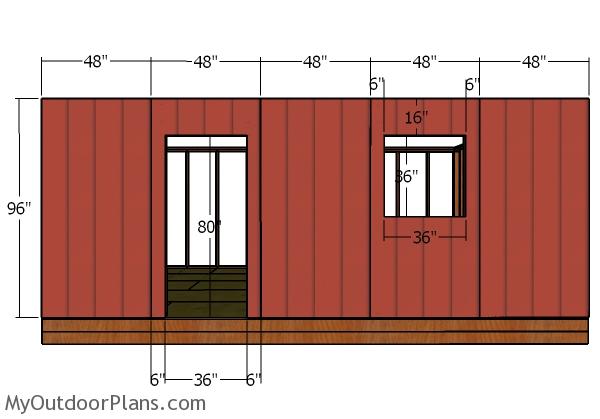

Building the side wall with window is the next step of the project. As you can see in the plans, you need to frame a 3′ side door and a 3’x3′ window, so you let the light inside the shed. You can adjust the size of the door or the size of the window so it suit your needs, especially if you already have purchased the items.

Moreover, you need to double the posts that are placed at both ends of the wall. Fit 1/2″ plywood sheets between double studs so you enhance the rigidity of the frame. Also, use 2×6 lumber and 1/2″ plywood for the headers.

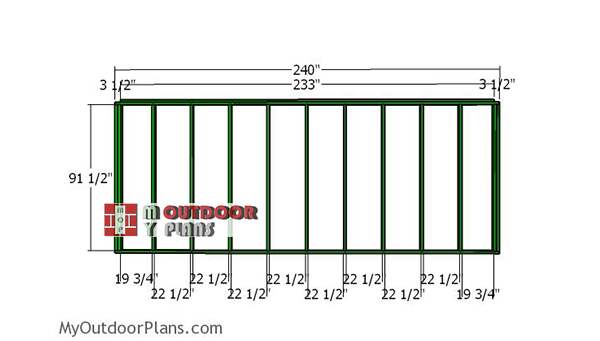

Side-plain-wall-frame

Last but not least, you need to frame the opposite side wall. Drill pilot holes through the plates and insert 3 1/2″ screws into the studs. Make sure the corners are square and that the edges are flush.

Assembling the shed frame

Next, fit the four wall frames to the floor of the shed. Align the edges flush and plumb them with a spirit level. Drill pilot holes though the bottom plates and insert 3 1/2″ screws to lock the walls into place tightly. Moreover, you have to lock the adjacent walls together tightly with 3 1/2″ screws. Make sure the edges are flush and the corners are square.

Step 3: Fitting the wall siding panels

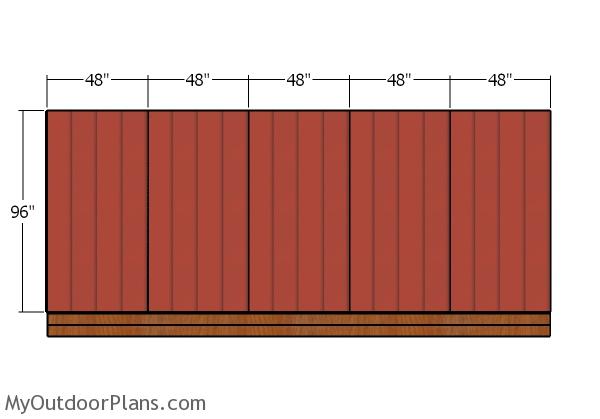

Side and back wall – siding

Fit T1-11 siding to the back wall and to the plain side wall of the 20×20 shed. Align the edges with attention and leave no gaps between the sheets. Use 6-8d nails to secure the sheets into place tightly, every 8″ along the framing.

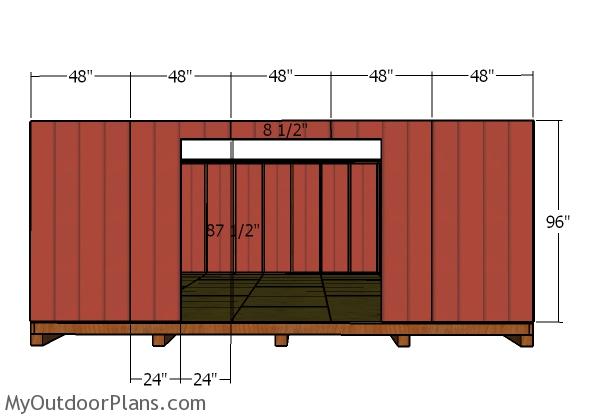

Front wall – Siding

The next step of the project is to attach the T1-11 siding sheets to the front of the 20×20 shed as well. Make the cuts to the panels that go around the door opening, so you can fit them into place tightly.

Side wall with window – Siding

Fit the siding sheets to the other side wall, as well. As you can see in the plans, you need to make cuts so you can fit the panels around the door and the door opening.

20×20 Shed Plans

Make sure you take a look over PART 2 of the project so you learn how to build the gable roof and PART 3 to learn how to build the doors and how to attach the trims.

20×20 Shed Plans – Side view with windows

This 20×20 shed is large enough to store a lot of items, while it is still easy enough to build in a do-it-yourself style. However, I recommend you to check out the local codes before starting the project so you learn how to get the job done legally. Premium Plans for this project available in the Shop.

If you want to get PREMIUM PLANS for this project (different design with re-engineered structure), in a PDF format, please press GET PDF PLANS button bellow. Thank you for the support.

This woodworking project was about 20×20 wood shed plans. If you want to see more outdoor plans, check out the rest of our step by step projects and follow the instructions to obtain a professional result.

12 comments

Very good detailed plans. Material list is a plus.

Thank you for the kind words.

Would there be a reasonable way to add more windows and a second set of double doors to this plan?

Need 20 x 20. Building

Have cement laid and ready

Can you help me

If I want to put this on 6X6 posts, do I make sure there is one every 4 feet like with the walls?

I’ve been looking for a 20X12 instead of 12X20. I want the roof joists to be 20 ft. wide. Could I use this plan and just cut off the other 8′?

Yes, you can do that. It’s the best choice for your needs.

Questions about foundation. Planning on insulating and using something like this as a small working woodshop. In a cold weather area is a concrete pad necessary? Or is floor laid on crushed stone or cinder block adequate?

If it were my shop, I would pour a foundation with insulation sheets under the concrete slab.

Question about ply wood 1/2 thick at one piece- in the wall you say sandwich it- are them just strips I would cut from the sheet?

Can you guys stamp these plans for local county requirements? Can I pay extra to have that done? Thanks! (That’s all that’s stopping me is the trusses needed to be “engineered”)

The best option for you is to buy pre made trusses (ex Menards). They will save you time and they usually come with the engineering stamp you need.