This step by step diy woodworking project is about sawbuck plans. If you want to learn more about building a wooden sawbuck, we recommend you to pay attention to the instructions described in the article. There are many other designs and plans to choose from when building projects for your backyard, so make sure you take a close look over the related plans that are featured on our site.

There are many plans and designs to choose from, so make sure you take a close look over the rest of the workshop plans featured on our website. Plan everything with attention and adjust the size and the shape of the table to suit your needs. Plumb the legs and make sure the corners are right-angled before inserting the galvanized screws into place. Drill pilot or pocket holes to prevent the wood from splitting. See all my Premium Plans HERE.

Projects made from these plans

Sawbuck plans

Building a sawbuck

Cut & Shopping Lists

- A – 6 pieces of 2×4 lumber – 36″ long LEGS

- B – 4 pieces of 1×4 lumber – 36″ long BRACES

- 2 pieces of 2×4 lumber – 10 ft

- 1 piece of 1×4 lumber – 12 ft

- 2 1/2″ screws

- 1 5/8″ screws

- 1 1/4″ screws

- wood filler

- wood glue

- stain/paint

Tools

![]() Hammer, Tape measure, Framing square, Level

Hammer, Tape measure, Framing square, Level

![]() Miter saw, Drill machinery, Screwdriver, Sander

Miter saw, Drill machinery, Screwdriver, Sander

Time

Related

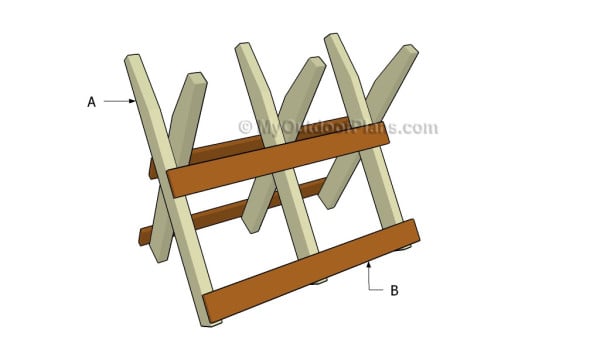

Building a sawbuck

Building the supports

The first step of the woodworking project is to build the legs for the sawbuck. Therefore, we recommend you to use 2×4 lumber for the legs of the sawbuck. Select straight slats and make sure they are in a good condition.

Mark the cut lines on the beams and get the job done with a circular saw. Smooth the cut edges with sandpaper and repeat the process for the rest of the legs, in the same manner described above.

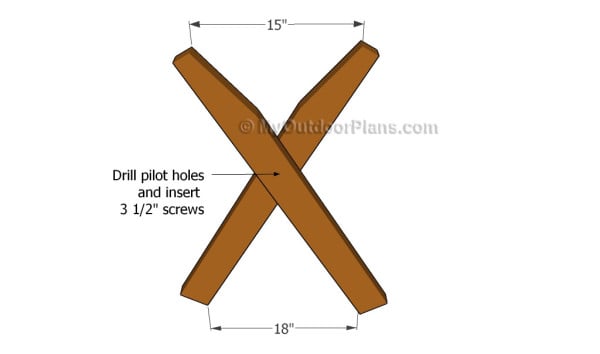

Building the X-shaped supports

The next step of the woodworking project is to build the X-shaped supports for the sawbuck. Align the components with great care and lock them together with several C-clamps. Drill pilot holes through the components and insert 3 1/2″ bolt screws. Insert 2 bolt screws in order to get a rigid structure.

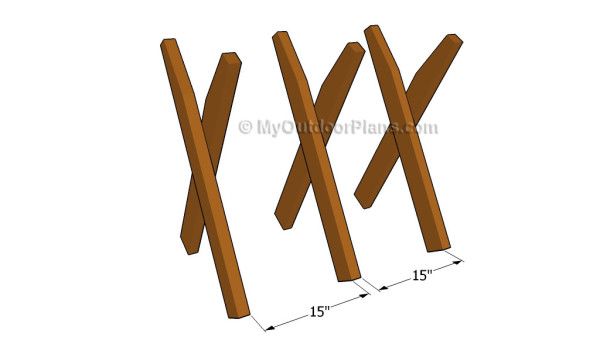

Building the frame of the sawbuck

Place the three X-shaped support equally spaced before attaching the wooden braces. It is essential to place the supports properly, otherwise the sawbuck won’t have a neat appearance.

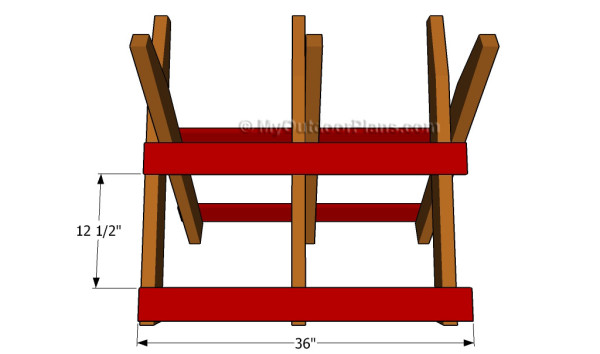

Fitting the supports

In order to create the wooden sawbuck for your workshop, we recommend you to attach the 1×4 braces to the X-shaped supports. Place the supports equally-spaced and make sure they are perfectly plumb, before attaching the braces. Work with attention and create strong joints.

Sawbuck plans

One of the last steps of the woodworking project is to take care of the finishing touches. Therefore, fill the pilot holes with wood putty and smooth the surface with 120-grit sandpaper.

Top Tip: If you want to enhance the look of the woodworking project and to protect the table from decay, we recommend you to cover the components with paint or stain. Place the bench in a proper location and move it whenever necessary.

This woodworking project was about sawbuck plans. If you want to see more outdoor plans, we recommend you to check out the rest of our step by step projects. LIKE us on Facebook and Google + to be the first that gets out latest projects.

2 comments

You have copied a little too much finishing text into this project! You don’t need to fill pilot holes, stain, or sand a sawbuck with 200 grit sandpaper!! I agree that slivers should be removed with coarse sandpaper after the wood is cut, that is SOP, otherwise no fancy finish is needed for something you are going to saw logs on, really. It isn’t Furniture!

There is no absolute truth. Everyone has it’s own approach and I thank you for sharing yours. I personally like my projects neat.