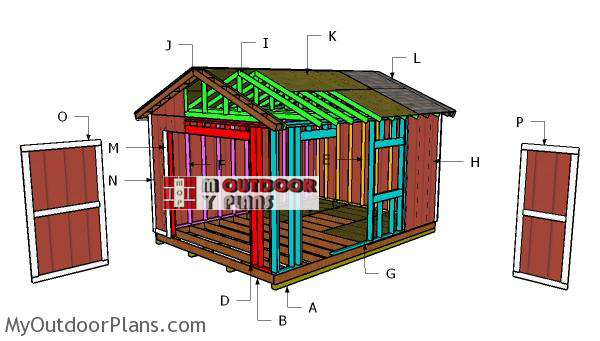

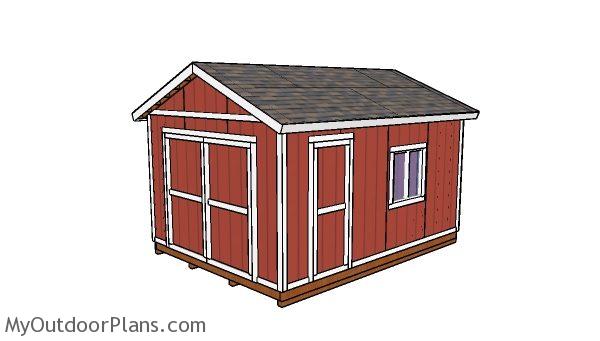

This step by step diy project is about 12×16 storage shed plans. I have designed this backyard shed so you can store tools, furniture and other items. This shed features a gable roof and large double front doors. In addition, the shed had a side door and a window to let a lot of light inside. Moreover, I have designed shed with many sizes so check them out, as well. Take a look over the rest of my woodworking plans, if you want to get more building inspiration.

When buying the lumber, you should select the planks with great care, making sure they are straight and without any visible flaws (cracks, knots, twists, decay). Investing in cedar or other weather resistant lumber is a good idea, as it will pay off on the long run. Use a spirit level to plumb and align the components, before inserting the galvanized screws, otherwise the project won’t have a symmetrical look. If you have all the materials and tools required for the project, you could get the job done in about a day. See all my Premium Plans HERE.

Projects made from these plans

It’s that simple to build a storage shed!

12×16 Storage Shed Plans

Building-a-12×16-garden-shed

Cut & Shopping Lists

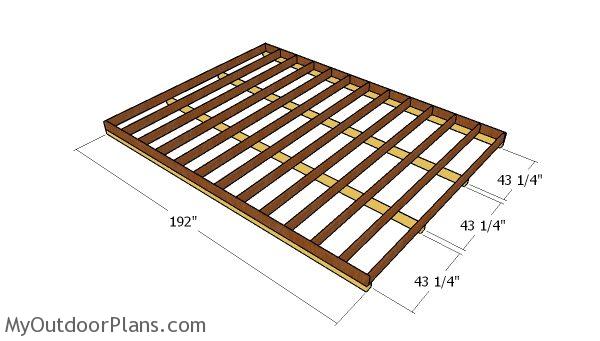

- A – 4 pieces of 4×4 lumber – 192″ long SKIDS

- B – 2 pieces of 2×6 lumber – 192″ long, 13 pieces – 141″long JOISTS

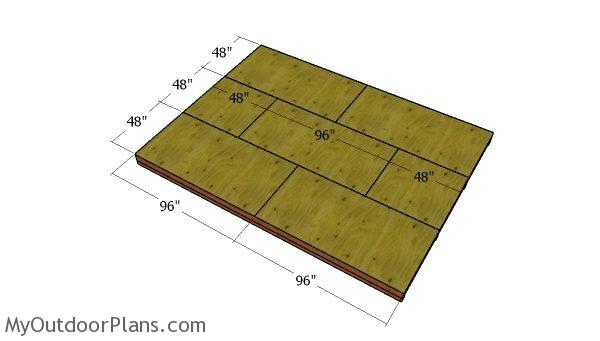

- C – 5 pieces of 3/4″ plywood – 48″x96″ long, 2 pieces – 48″x48″ long FLOOR

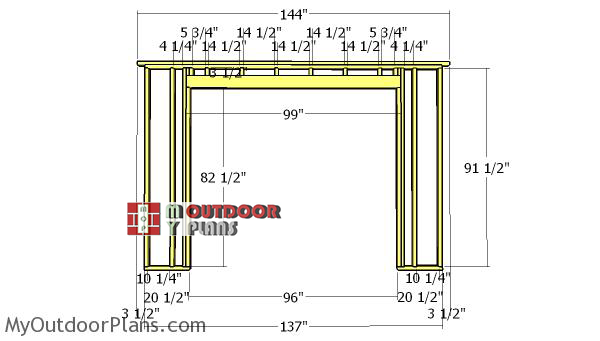

- D – 1 piece of 2×4 lumber – 144″ long, 1 piece – 137″ long, 2 pieces – 20 1/2″ long, 6 pieces – 91 1/2″ long, 2 pieces – 82 1/2″ long, 10 pieces – 3 1/2″ long, 2 pieces of 2×6 lumber – 99″ long FRONT WALL

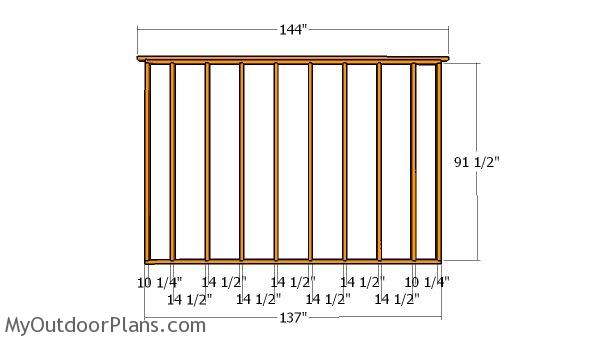

- E – 2 pieces of 2×4 lumber – 144″ long, 1 piece – 137″ long, 10 pieces – 91 1/2″ long BACK WALL

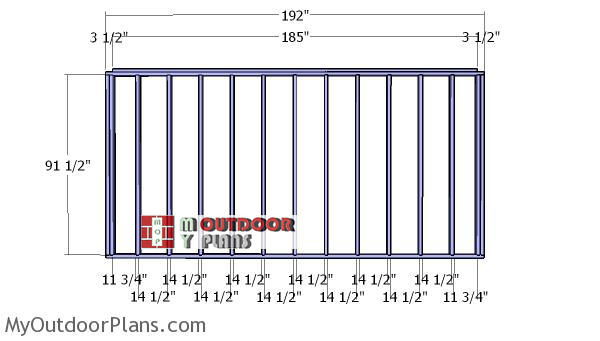

- F – 2 pieces of 2×4 lumber – 192″ long, 1 pieces – 185″long, 15 pieces – 91 1/2″ long SIDE WALL

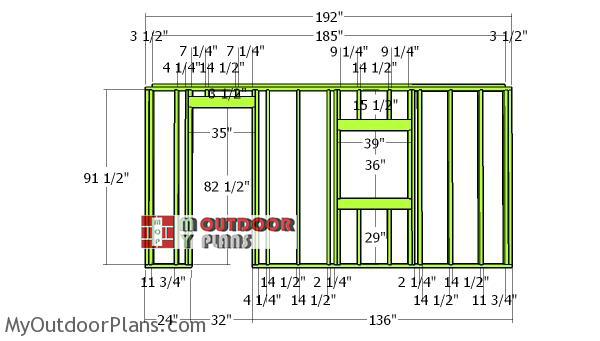

- G – 1 piece of 2×4 lumber – 192″ long, 1 pieces – 185″long, 1 piece – 11 3/4″ long, 1 piece – 136″ long, 2 pieces – 82 1/2″ long, 5 pieces – 3 1/2″ long, 4 pieces – 15 1/2″ long, 2 pieces – 36″ long, 4 pieces – 29″ long, 2 pieces – 35″ long, 4 pieces – 36″ long, 15 pieces – 91 1/2″ long SIDE WALL

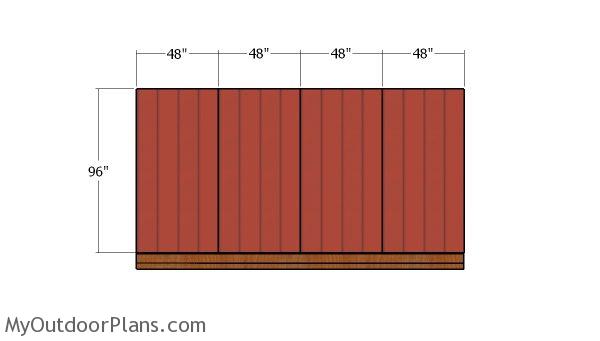

- H – 12 pieces of T1-11 – 48″x96″ long, 1 piece – 12″x48″ long WALL SIDING

- 2 pieces of 2×6 lumber – 16′

- 13 pieces of 2×6 lumber – 12′

- 2 pieces of 2×6 lumber – 10′

- 3 pieces of 2×6 lumber – 6′

- 6 pieces of 2×4 lumber – 16′

- 5 pieces of 2×4 lumber – 12′

- 55 pieces of 2×4 lumber – 8′

- 6 pieces of 3/4″ plywood – 4’x8′

- 4 pieces of 4×4 lumber – 16′

- 13 pieces of T1-11 – 48″x96″

- 1 piece of 1/2″ plywood – 48″x96″

- 8d nails, 2 1/2″ screws, 3 1/2″ screws, 1 5/8″ screws

- wood filler , wood glue, stain/paint

Tools

![]() Hammer, Tape measure, Framing square, Level

Hammer, Tape measure, Framing square, Level

![]() Miter saw, Drill machinery, Screwdriver, Sander

Miter saw, Drill machinery, Screwdriver, Sander

Time

Related

- PART 1: 12×16 Storage Shed Plans

- PART 2: 12×16 Storage Shed Roof Plans

- PART 3: 12×16 Storage Shed Door and Trims Plans

How to build a 12×16 storage shed

Floor-frame—12×16-shed

The first step of the project is to build the floor frame. Cut the joists from 2×6 lumber. Drill pilot holes through the rim joists and insert 3 1/2″ screws into the perpendicular components. Make sure the corners are square and align the edges flush.

Fitting the skids

Select the location for the shed after reading the local codes. Lay a layer of gravel to the ground and then compact it thoroughly. Fit 4×4 skids under the floor frame and secure them together tightly with rafter ties.

Fitting the floor sheets

Fit the 3/4″ plywood sheets to the floor frame. Align the edges flush and insert 1 5/8″ screws every 8″ along the framing. Leave no gaps between the sheets for a professional result.

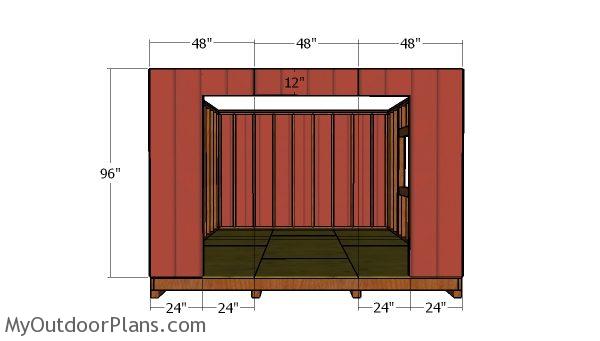

front-wall-frame

Build the front wall frame for the shed from 2×4 lumber. Cut the components at the right dimensions and then assemble the with 3 1/2″ screws, after drilling pilot holes. If you have a nail gun, you could lock the components together with nails. Align the edges flush and make sure the corners are square. Use 2×6 lumber and 1/2″ plywood for the double header (sandwich the plywood between the 2×6 beams with 2 1/2″ screws).

Back wall – frame

Assemble the back wall for the shed from 2×4 lumber, as well. After you cut the component from 2×4 lumber, you need to lay them on a level surface. Place the studs every 16″ on center. Make sure the corners are square and align the edges flush. Drill pilot holes through the plates and insert 3 1/2″ screws into the studs.

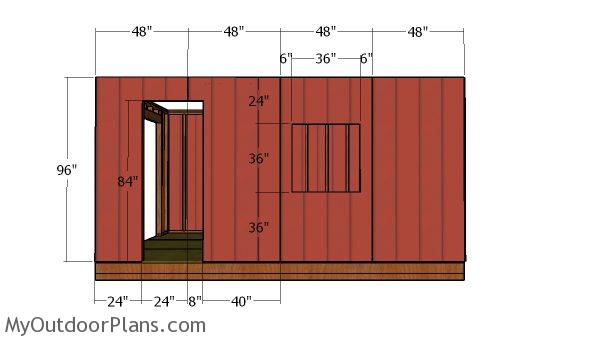

side-wall-with-window-and-door-frame

One of the walls will have a door opening for a man door and an opening for a large window. In this manner, you can access the shed easily and you will have plenty of light inside. Use 2×6 lumber and 1/2″ plywood for the double headers. Remember that you can adjust the door and window openings to suit your needs.

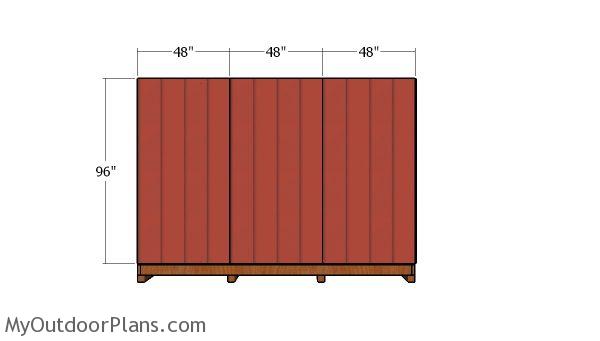

side-wall-frame

Assemble the opposite side wall for the shed from 2×4 lumber. Drill pilot holes through the plates and insert 3 1/2″ screws into the studs. Place the studs every 16″ on center. Place double studs at both ends of the wall. Make sure the corners are square, for a professional result.

Assembling the shed frame

Lay the four wall frames to the floor frame and align the edges flush. Drill pilot holes through the bottom plates and insert 3 1/2″ screws into the floor. Make sure you lock the adjacent walls together tightly with 3 1/2″ screws. Drill pilot holes before inserting the screws, to prevent the wood from splitting.

Side wall – siding

Fit the T1-11 siding sheets to the side wall of the shed, as shown in the diagram. Leave no gaps between the sheets and insert 6-8d nails, every 8″ along the framing.

Side wall with windows – siding

Fit the siding sheets to the opposite side wall of the shed. Make the cuts so you create the openings and align the edges with attention.

Back wall – siding

Fit the siding sheets to the back of the shed. Align the edges flush and insert 6-8d nails, every 8″ along the framing.

Front wall – siding

Fit the siding sheets to the front of the shed, as shown in the diagram. Make the cuts to the sheets so you can fit them into place properly. Insert 6-8d nails, every 8″ along the framing. Leave no gaps between the sheets for a professional result.

12×16 Storage Shed Plans

You need to take a look over PART 2 and PART 3 of the project, so you learn how to frame the roof and to learn how to build the doors.

12×16 Storage Shed Plans – Side view

Make sure you check out the rest of the project, so you learn how to frame the roof and how to attach the door and the trims to the shed. In addition, I have lots of other shed projects on the site so I recommend you to browse through all alternatives before starting the building project.

If you want to get PREMIUM PLANS for this project (different design and re-engineered structure), in a PDF format, please press GET PDF PLANS button bellow. Thank you for the support.

This woodworking project was about 12×16 storage shed plans free. If you want to see more outdoor plans, check out the rest of our step by step projects and follow the instructions to obtain a professional result.

30 comments

I’m planning to build this shed, but I want my double doors to be 6 ft wide, not 8 ft. I’m also going to use 90 in studs instead of 91 1/2. (I want the siding to overhang 3/4″ over the top and bottom plates.)

Basically, I want your ATV shed plans with a 6 ft wide double door, not roll-up, with the roof from this plan all on 16 in. centers. What would the difference in materials be? And would the bottom plates of the front wall need to be 32 1/2″ long?

Yes, the plates will be 32 1/2″ long. And you will probably need 2 more studs for the front.

I’ve double-checked the sidewall with the door and window and I loose a full inch when marking my plates. The 24″ space to the inside door jamb is actually 23.5″ and the long wall measurement to inside door jamb is 135.5″ instead of 136″. This is based on adding up the stud widths and spaces on your drawing. What am I missing?

What is the diagram you are referring to? I’m trying to understand but the measurements you give don’t match up with the side wall with window and door.

This is the image I am referring to:

http://myoutdoorplans.com/wp-content/uploads/2017/04/side-wall-with-window-frame.jpg

The long wall with the window and door is 192″ (16ft). The distance to the door from the nearest edge is listed as 24″, but actually comes out to 23.5″ (7 studs @1.5″ wide + 11.75″ space and 4.25″ space). The longer section is listed as 136″ but actually comes out to 135.5″ if you add up the stud widths and spaces. So I ended up off by an inch marking my plates. I adjusted this when building, but I thought you should take a look at the drawing and correct.

Okay. I’ve got it now. You are missing something, between the double end studs is a 1/2″ gap. I haven’t highlighted the gap on the diagram because I have shown the double studs are aligned with the top plate, which is 3 1/2″ recessed (2 studs x 1 1/2″ + 1/2″ gap). Same for the other side of the wall.

Excellent plans. Thank you. I am going to move the single door away from the double doors so my mower is in one end of the shed and access to everything else via the single door is easier without climbing over the mower.

That’s a good idea. Good luck and let me know how it comes out!

In the material list, there is 1 piece of 1/2″ plywood – 48″x96″. Where do you use this for?-Thanks

That’s for the double headers and for the blockings between the double studs.

Thank you for answering the question earlier. For trim, does it have to be pressure treated as well? Or i can use the regular soft board and paint it?

No need to be pressure treated.

Thank you for the response. Could you please provide an estimate of the screws and nails? Thanks!

You have those estimates in the Premium Plans.

Can you recommend a nail gun for the project?

This one: https://amzn.to/3fXYry4

The window cut out is 36×39, does it mean i need to purchase the window of 36×39? Can you recommend the place for windows?

The window is 36×36, the 39 is the size of the header. I have no recommendation for windows. Any PVC window will work.

Is the 1/2 inch plywood necessary to be filled in between the double studs?

Yes. If it weren’t why would I have mentioned it?

Can you provide the link of the rafter ties? Looks like there are different types.

This: https://amzn.to/31rhcFS

Hi, in the material list, for 2×4 8ft x28 pieces, the cut is 88″ with the angle and 4 1/2″…. what is the 4 1/2 for? I thought the rafter is to cut to 88″ in total.

The 4 1/2″ are blockings for the overhangs.

Can you please clarify the reason of this 1/2 plywood between the double studs? I am trying to understand.

A stud is 3 1/2″ wide. 2×1 1/2″ is 3″, so you need the extra 1/2″ plywood. In addition, the plywood makes the frame sturdier.

On the material list, the Truss Support -2×4 lumber 26 3/8″ long. However, on the cut sheet, it says 26 1/4″. Which one is the correct one?

It is the same thing, you can’t get a 26 3/8″ cut anyway.

Do you have a version of this shown with a post and pier foundation?

No