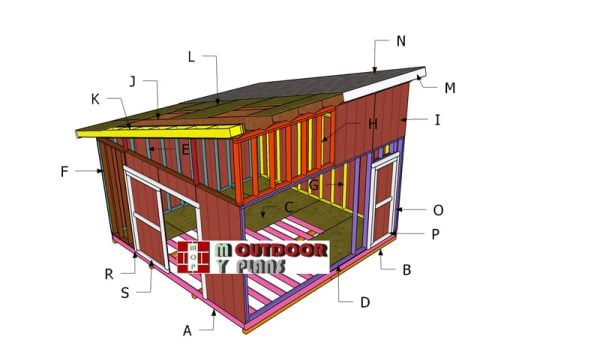

This step by step diy project is about 16×16 lean to roof plans. This is PART 2 of the large shed project, where I show you how to build the lean to roof. The roof has a 3:12 pitch. This shed features large overhangs on the sides, front and back. Make sure you check the local codes and make adjustments to the plans, if required. Take a look over the rest of my woodworking plans, if you want to get more building inspiration.

When buying the lumber, you should select the planks with great care, making sure they are straight and without any visible flaws (cracks, knots, twists, decay). Investing in cedar or other weather resistant lumber is a good idea, as it will pay off on the long run. Use a spirit level to plumb and align the components, before inserting the galvanized screws, otherwise the project won’t have a symmetrical look. See all my Premium Plans HERE.

Projects made from these plans

16×16 Lean To Shed Roof Plans

Building-a-16×16-lean-to-shed

Cut & Shopping Lists

Tools

![]() Hammer, Tape measure, Framing square, Level

Hammer, Tape measure, Framing square, Level

![]() Miter saw, Drill machinery, Screwdriver, Sander

Miter saw, Drill machinery, Screwdriver, Sander

Time

Related

- PART 1: 16×16 Shed Plans

- PART 2: 16×16 Lean to Shed Roof Plans

- PART 3: 16×16 Shed Door Plans

Building a 16×16 lean to shed roof

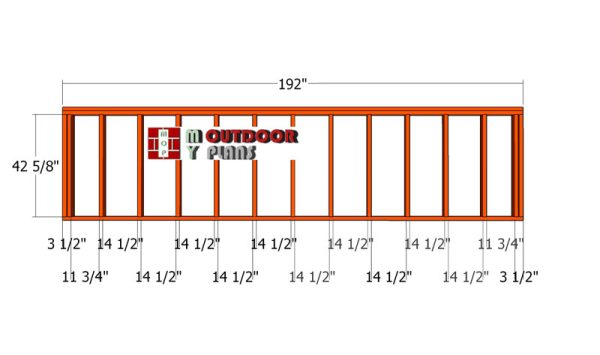

Top-wall-frame

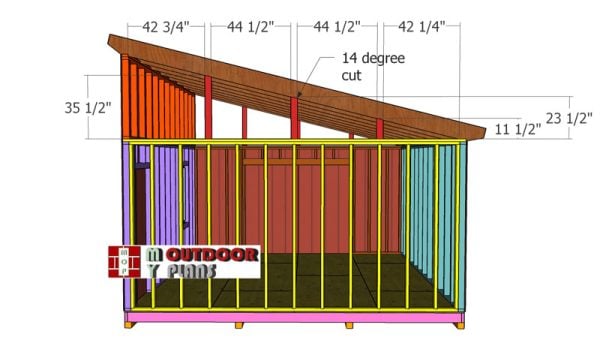

The first step of the project is to build the top frame for the front wall of the shed. Cut the components from 2×4 lumber at the dimensions shown in the diagram.

Drill pilot holes through the plates and insert 3 1/2″ screws into the studs. Place the studs every 16″ on center, for a professional result. Make sure the corners are square and align the edges with attention. Use double studs at both ends of the wall and fit 1/2″ plywood between.

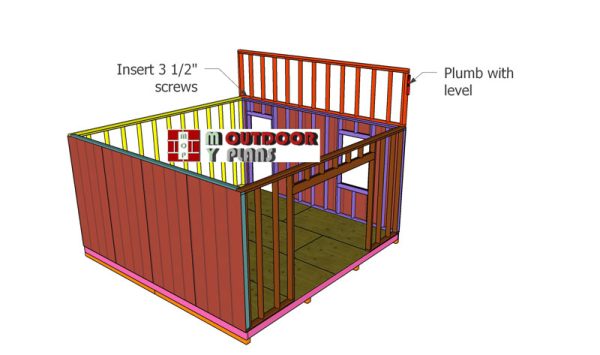

Attaching-the-top-wall-frame

Fit the wall frame to the top of the back wall. Align the edges with attention and plumb it with a spirit level. Drill pilot holes through the bottom plates and insert 3 1/2′ screws into the wall.

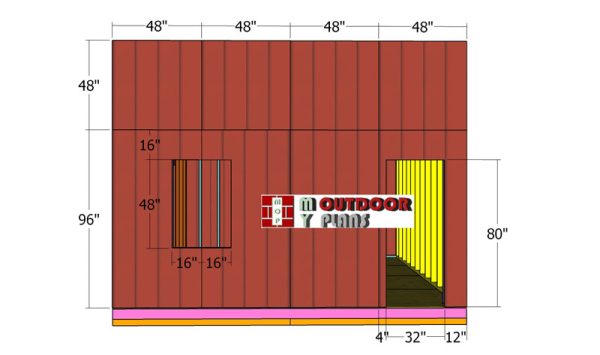

Front-wall-siding-sheets

Next, fit the T1-11 siding panels to front wall. Align the edges with the top edges of the wall frame and insert 2″ nails, every 8″ along the framing. Leave no gaps between the sheets for a professional result. Make the cuts for the window and door openings.

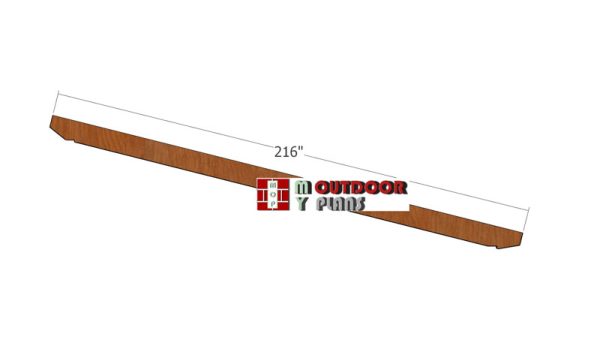

Rafters

Use 2×10 lumber for the rafters. You need this size because of the large opening of the roof.

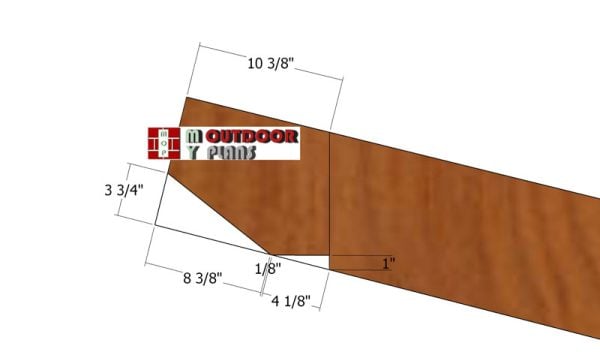

Top-birdsmouth-cut

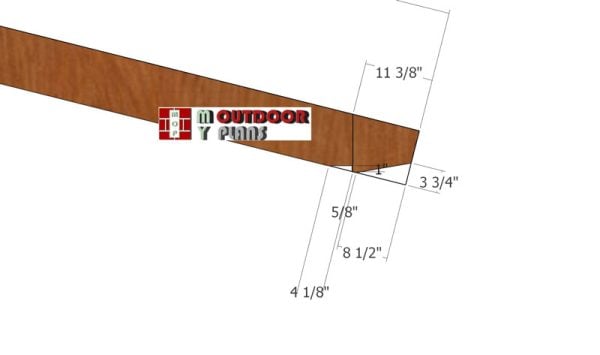

Bottom-birdsmouth

Mark the cut lines on the boards and then get the job done with a circular saw. Take accurate measurements and make sure the blade goes over the cut line, otherwise the rafters won’t fit into place. The bird-mouth cuts will help you lay the rafters to the top plates easily.

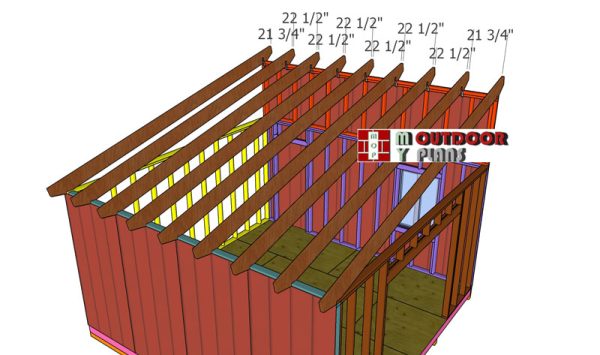

Fitting-the-rafters

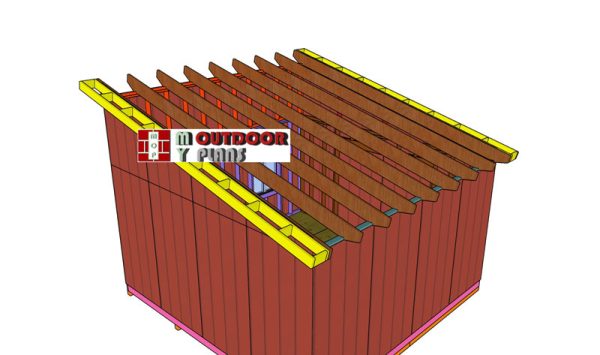

Fit the rafters to the top of the shed, every 16″ on center. Use rafter ties and 1 1/2″ screws to lock the rafters into place tightly.

Fitting-the-lean-to-roof-supports

Use 2×4 lumber for the side lean to supports. Use a miter saw to make the angle cuts to the supports and then drill pocket holes at both ends. Fit the supports into place and then lock them into place with 2 1/2″ screws.

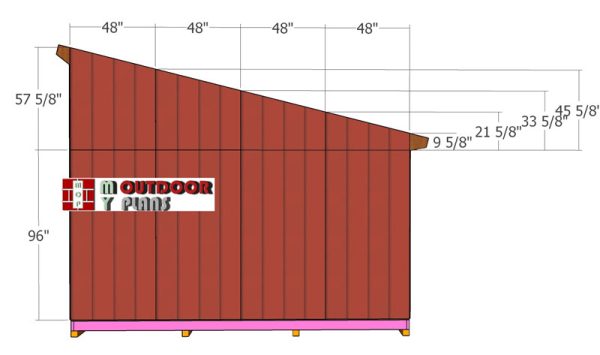

Side-siding-sheets

Cut the T1-11 siding panels to the right dimensions, using the information from the diagram. Fit the T1-11 siding sheets to the sides of the shed. Align the edges and insert 6d nails, every 8″ along the framing.

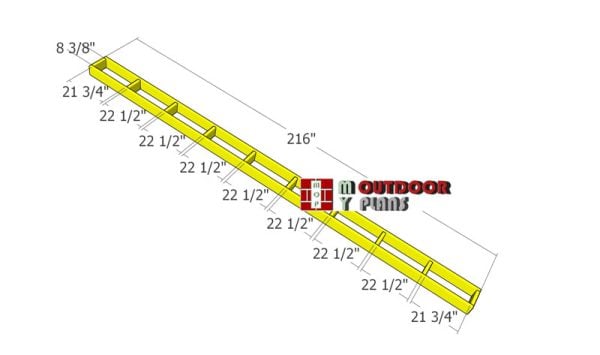

Assembling-the-roof-overhangs

Use 2×6 lumber for the side overhangs. Cut the components at the right dimensions and then lock them together tightly with 3 1/2″ screws. Make sure the edges are flush and check if the corners are square. You can easily adjust the size of the overhangs by making the blockings shorter or larger.

Fitting-the-side-overhangs

Fit the overhangs to the sides of the shed and align the edges with attention. Drill pilot holes and insert 3 1/2″ screws to lock them into place tightly. Double-check if the overhangs are locked into place tightly.

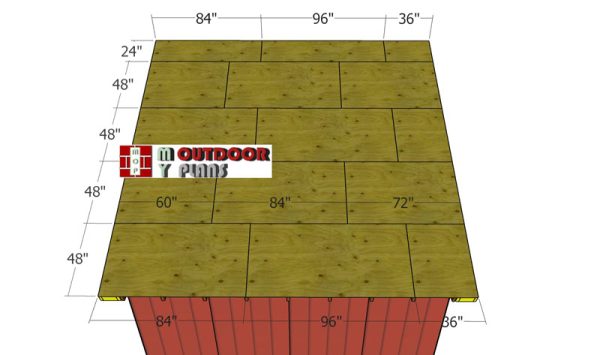

Roof-sheets

Cut the roof sheets from 1/2″ plywood, using the information from the diagram. Fit the 3/4″ plywood sheets to the roof of the shed. Align the edges with attention and insert 1 5/8″ screws, every 8″ along the framing.

Side-roof-trims

Front-roof-trims

Fit 1×8 trims to the sides of the roof. Fit 1×8 trims to the front and back of the shed roof. Align the edges with attention, drill pilot holes and insert 2″ screws/nails to lock them into place tightly.

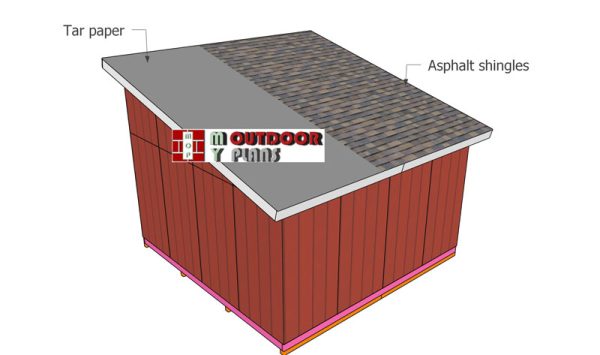

Fitting-the-roofing

Begin by installing a drip edge along the eaves of the lean-to shed roof, securing it with roofing nails. This helps prevent water damage and directs water away from the structure. Next, apply an underlayment, such as roofing felt, starting at the bottom edge and working your way up the roof.

Overlap each row to create a watertight barrier. Position starter shingles along the eaves, ensuring they overhang the edge slightly. This provides a solid foundation for the rest of the asphalt shingles. Install the first course of asphalt shingles over the starter strip, aligning them with the chalk lines for a straight and uniform appearance.

Continue installing subsequent courses of shingles, staggering the seams to enhance stability and water resistance. Nail each shingle in place, following the manufacturer’s recommendations. Finish the roof by trimming any excess overhang and adding ridge caps along the ridge line, securing them with roofing nails. This creates a durable and weather-resistant asphalt shingle roof for your lean-to shed.

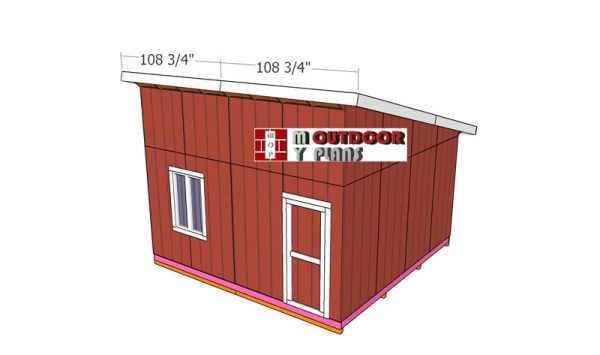

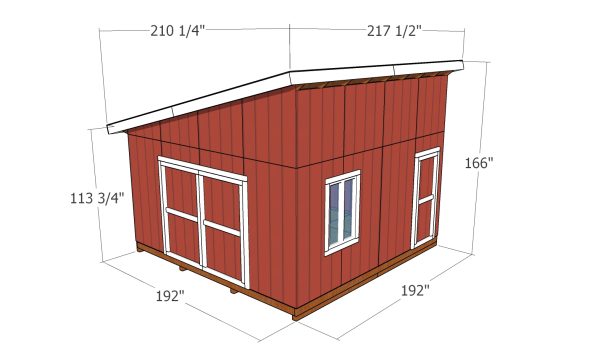

16×16 lean to shed plans – overall dimensions

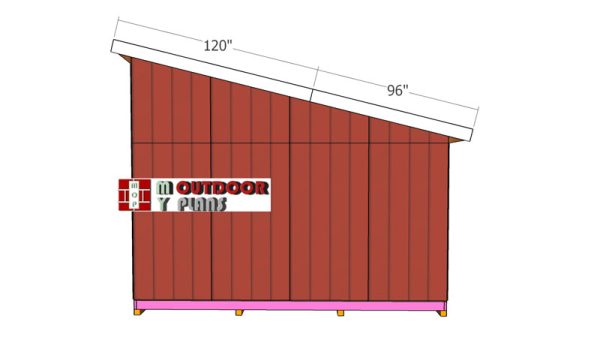

16×16 lean to shed plans – back view

I have lots of other shed projects on the site so I recommend you to browse through all alternatives before starting the building project. See all my shed projects HERE. Moreover, check out PART 1 of the shed, so you learn how to build the frame of the shed. Check out PART 3 of the shed, so you learn how to build the double doors.

This woodworking project was about 16×16 lean to shed roof plans. If you want to see more outdoor plans, check out the rest of our step by step projects and follow the instructions to obtain a professional result.