This step by step diy project is about 12×24 garden shed plans. This large garden shed features a gable roof with generous overhangs, a front man door, two 36″x36″ windows and a 8’x7′ garage door to the side. Moreover, the roof has a 6:12 pitch. Take a look over the rest of my woodworking plans, if you want to get more building inspiration. Remember that you need to select the site for the shed with attention and that you have to comply with a few legal regulations. Premium Plans for this project available in the Shop.

When buying the lumber, you should select the planks with great care, making sure they are straight and without any visible flaws (cracks, knots, twists, decay). Investing in cedar or other weather resistant lumber is a good idea, as it will pay off on the long run. Use a spirit level to plumb and align the components, before inserting the galvanized screws, otherwise the project won’t have a symmetrical look. If you have all the materials and tools required for the project, you could get the job done in about a day. See all my Premium Plans HERE.

Projects made from these plans

12×24 Garden Shed Plans – PDF Download

Building-a-12×24-gable-shed

Cut + Shopping Lists

Tools

![]() Hammer, Tape measure, Framing square, Level

Hammer, Tape measure, Framing square, Level

![]() Miter saw, Drill machinery, Screwdriver, Sander

Miter saw, Drill machinery, Screwdriver, Sander

Time

Related

- PART 1: 12×24 Shed Plans

- PART 2: 12×24 Shed Roof Plans

- PART 3: 12×24 Shed Doors Plans

It’s that easy to build a large shed!

Step 1: How to build the floor for 12×24 shed

Floor-frame—12×24

The first step of the project is to build the floor frame for the shed. Cut all the joists from 2×6 lumber and then lay them on a level surface. Make sure you place the joists every 16″ on center, for a professional result.

Drill pilot holes through the rim joists and insert 3 1/2″ screws into the perpendicular joists. Make sure the corners are square for a professional result. Measure the diagonals and make adjustments until they are perfectly equal.

Fitting-the-skids

Select the location for the shed and then level it properly. Compact a layer of gravel to the location and the lay the 4×4 skids. Fit the floor frame to the skids and then use rafter ties to connect them tightly (one at each end of the skids). Insert 1 1/2″ structural screws to lock the connectors.

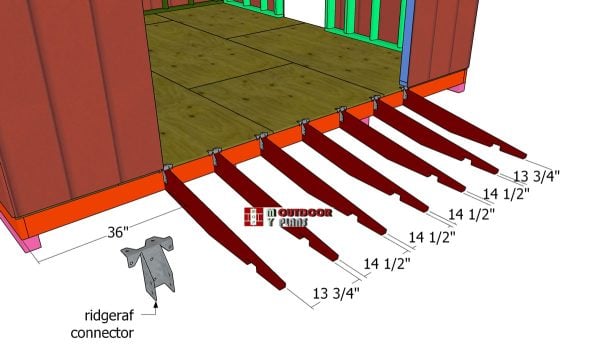

Ramp-joists

Next, we need to cut the joists for the ramp. Mark the cut lines on the beams and get the job done with a circular saw. Smooth the edges flush.

Fitting-the-ramp-joists

Secure the joists to the frame of the shed with ridge rafters and 1 1/2″ structural screws. Place the joists every 16″ on center, as indicated in the diagram.

Fitting-the-ramp-support

After fitting the joists to the floor of the shed, you need to lock them together with a 2×4 board. Fit the board to the base of the joists, making sure the joists are spaced every 16″ on center.

Fitting-the-floor-sheets

Lay the 3/4″ plywood sheets to the floor frame and align the edges flush. Drill pilot holes every 8″ along the framing and insert 1 5/8″ screws. Leave no gaps between the sheets for a professional result.

Fitting-the-ramp-slats

Fit the 1×6 boards to the ramp. Align the boards at both ends and secure them into place with 1 5/8″ screws. Drill pilot holes before inserting the screws to prevent the wood from splitting.

Step 2: Building the shed wall frames

Side-wall-frame—garage-door

Double-header-front-wall

Build the side wall frame for the 12×24 shed using 2×4 lumber for the studs and plates, and 2×6 lumber for the double headers. Drill pilot holes through the plates and insert 3 1/2″ screws into the studs. Make sure the corners are square and align the edges flush.

Notice the door opening opening. We need to assemble double headers for the door opening. Glue a piece of 1/2″ plywood between the 2×6 beams. Align the edges flush and make sure you add glue to the joints. Insert 2 1/2″ screws from both sides.

Side-wall-frame

Build the other side wall for the shed from 2×4 lumber, as well. Drill pilot holes through the plates and insert 3 1/2″ screws into the studs. Notice the top double plates.

Back-wall-frame-structure

Build the back wall frames from 2×4 lumber, using the same techniques described above. Place the studs every 16″ on center and then make sure the corners are square.

As you can easily notice in the diagram, you need to place double studs to one end of the walls. Make sure the corners are square and align the edges flush. For the 24′ long walls we will need two 12′ sections. This makes the walls easier to move and cheaper to make.

Front-wall-partition-1

Frame the front wall for the garden shed. Notice the large window. The opening has double headers. Use the techniques described above to build the headers. Place the studs every 16″ on center.

Front-wall-partition-2

Build the other section for the front wall using the information in the diagram. Notice the window and door openings. You can make adjustments to the openings, if necessary.

Fitting-the-front-wall-partitions

Fit the front and back wall frames to the floor of the shed. Plumb the wall frames with a sprit level and align them flush with the floor sheets. Drill pilot holes and insert 3 1/2″ screws into the floor of the shed. Notice the temporarily 2×4 braces that hold the walls into place, until you fit the side frames.

Assembling-the-shed-frame

Fit the side wall frames to the floor of the shed. Align the edges flush and plumb them vertically with a spirit level. Drill pilot holes through the bottom plates and insert 3 1/2″ screws into the floor. Lock the adjacent walls together by inserting 3 1/2″ screws.

Double-top-plates

Fit the double plates to the front and back wall frames. Align the edges and insert 2 1/2″ screws to lock the plates into place tightly.

Step 3: Fitting the shed siding panels

Front-wall-panels

Fit the T1-11 siding sheets to the front of the shed. Align the edges flush and lock them into place tightly with 6-8d nails. Insert the nails every 8″ along the framing and leave no gaps between the sheets. Cut out the window and door openings and smooth the edges with sandpaper.

Fit the panels to the back wall, as well. Use 6-8d nails to secure the sheets to the framing (same dimensions, but without the opening cutouts).

12×24-Gable-Shed—full-dimensions

Make sure you check out PART 2 of the project, where I show you how to build the roof for the shed. Take a look over PART 3 of the project, where I show you how to build the double door and how to fit the trims.

12×24 Storage Shed Plans

This 12×24 shed with a gable roof is a good choice if you want to combine the storage space wit the easy accessibility and with the looks. This shed can add a lot of value to the property with a small investment. The return is awesome, especially if you build it by yourself! Premium Plans for this project available in the Shop.

Check out the Premium Plans for this design. They include the full Cut and Shopping lists, as well as plans for building the shed ramp and the window flower box. To get the Premium plans just press the GET PDF PLANS button bellow.

This woodworking project was about 12×24 shed plans free. If you want to see more outdoor plans, check out the rest of our step by step projects and follow the instructions to obtain a professional result.