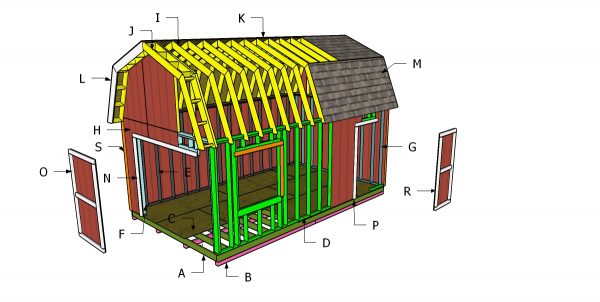

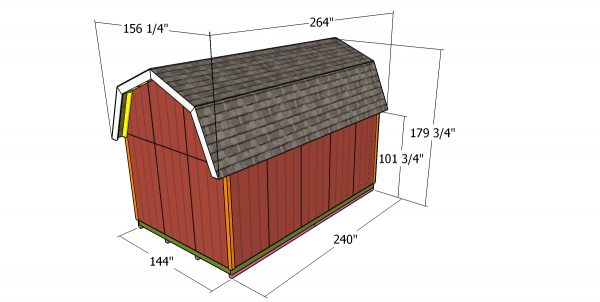

This step by step diy woodworking project is about 12×20 gambrel shed plans. The project features instructions for building a large shed with one large window and one access door on the side and double doors to the front. If you want to create backyard storage space or even a small studio, building this large shed is a great idea. Make sure you take a look over the rest of plans to see alternatives and more projects for your garden.

When buying the lumber, you should select the planks with great care, making sure they are straight and without any visible flaws (cracks, knots, twists, decay). Investing in cedar or other weather resistant lumber is a good idea, as it will pay off on the long run. Use a spirit level to plumb and align the components, before inserting the galvanized screws, otherwise the project won’t have a symmetrical look. If you have all the materials and tools required for the project, you could get the job done in about a day.

Projects made from these plans

12×20 Gambrel Shed Plans

Building a 12×20 gambrel shed

Cut & Shopping List

Tools

![]() Hammer, Tape measure, Framing square, Level

Hammer, Tape measure, Framing square, Level

![]() Miter saw, Drill machinery, Screwdriver, Sander

Miter saw, Drill machinery, Screwdriver, Sander

Time

![]() One week

One week

It’s that easy to build a gambrel shed!

How to build a large 12×20 barn shed

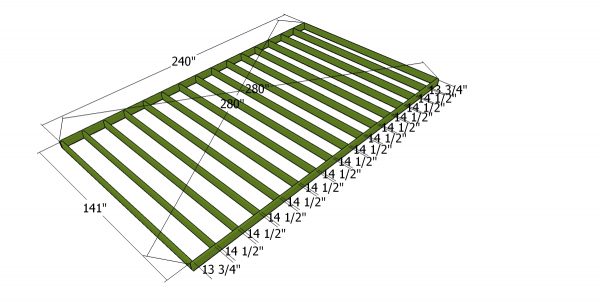

Floor frame

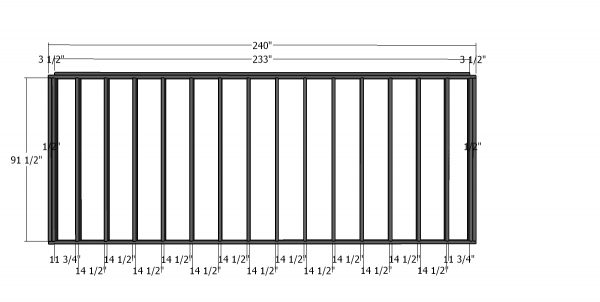

The first step of the project if to assemble the floor frame. Cut the components from 2×6 lumber at the right size. Drill pilot holes through the rim joists and insert 3 1/2″ screws into the regular joists. Place the joists equally-spaced, as shown in the plans. Make sure the edges are flush and check if the corners are right-angled. Measure the diagonals and make adjustments until they are equal.

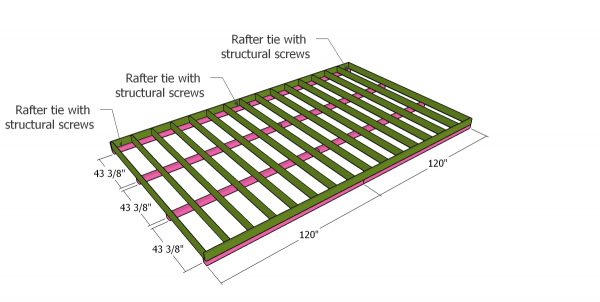

Fitting the skids

Fit 4×4 skids under the floor frame, in order to protect the components from moisture. Use rafter ties and 1 1/2″ structural screws to lock the skids to the floor frame. Use at least 2 ties for each skid.

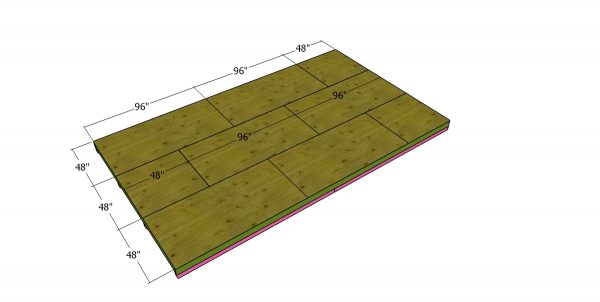

Floor sheets

Attach the 3/4″ plywood sheets to the floor frame, making sure you follow the patterns described in the diagram. Leave no gaps between the sheets and secure them to the joists using 1 5/8″ screws, every 8″. Use tongue and groove plywood sheets, for a professional result.

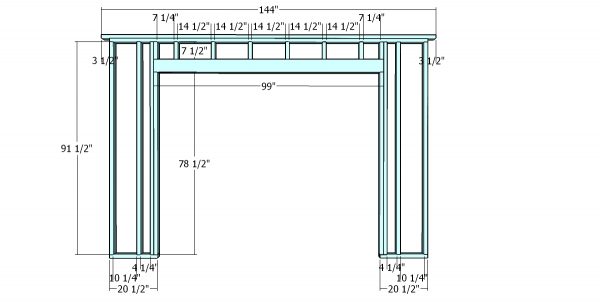

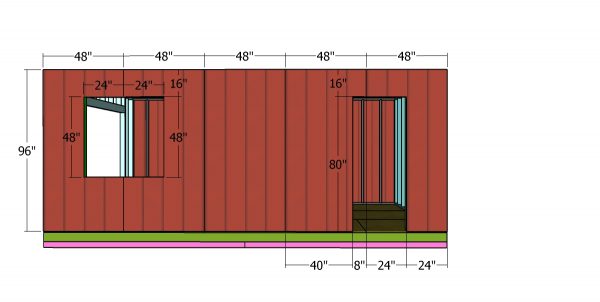

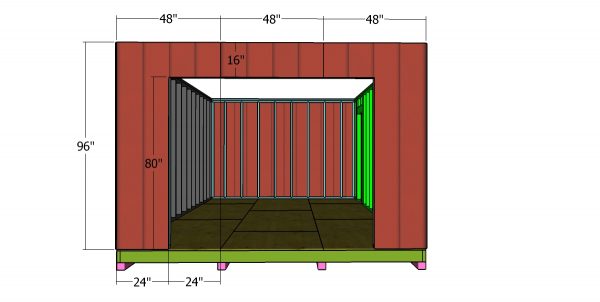

Front wall frame

Next, we need to build the front wall with double door opening. Use 2×4 for the studs and plates, and 2×6 lumber for the double header. Drill pilot holes through the plates and insert 3 1/2″ screws into the studs. Use at least 2 screws for each joint. Place the studs as shown in the diagram. Drill pilot holes and secure the header to the side studs.

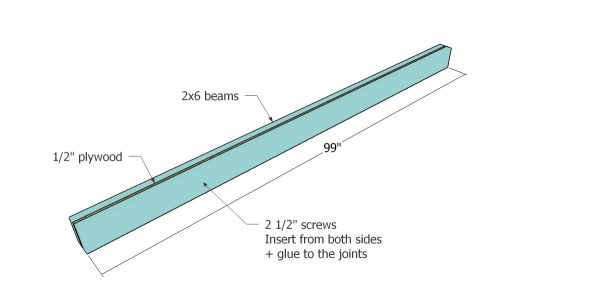

Assembling the double header

Notice the double header. You need to place 1/2″ plywood between the double beams. Add glue to the joints and insert 2 1/2″ screws from both sides.

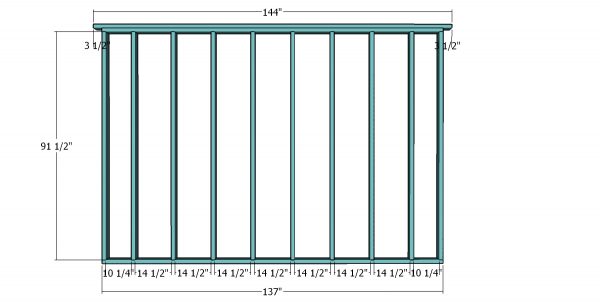

Back wall frame

Assemble the back wall for the shed using 2x4s. Drill pilot holes and insert 3 1/2″ screws into the studs. Use 2 1/2″ screws for the double plate. Notice it overhangs 3 1/2″ on both sides.

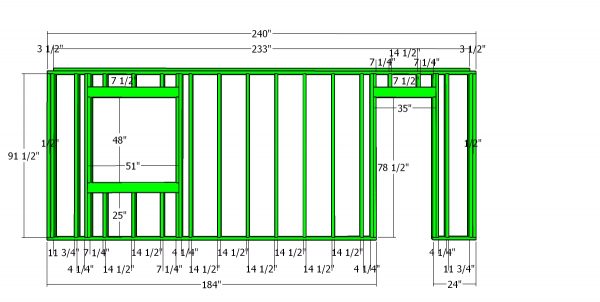

Side wall with window

Build the front wall from 2×4 lumber. Cut the components at the right dimensions, making sure you follow the information from the plans. Drill pilot holes through the plates and insert 2 1/2″ screws into the studs or 16d nails.

Make sure the corners are right-angled and check if the edges are flush. As you can easily notice, you need to frame the door opening and the window opening. You can adjust the dimensions for the walls to suit your needs. Notice the double headers for the door and window.

Plain side wall frame

Building the back wall is an easier job, as it doesn’t require intricate measurements and cuts. Drill pilot holes through the top and bottom plates and insert 3 1/2″ screws into the studs. Place the studs equally-spaced and make sure the corners are right-angled.

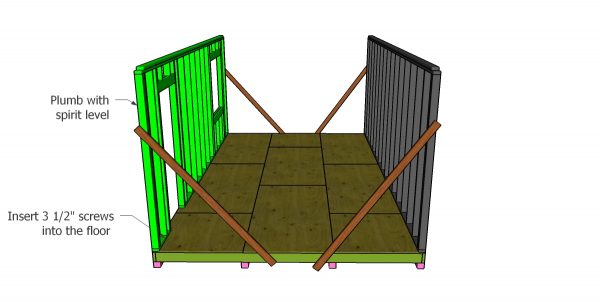

Fitting the side walls

Fit the side walls to the floor and use temporary braces to lock them into place. Plumb the walls with a spirit level and align the edges with attention. Drill pilot holes through the bottom plates and insert 3 1/2″ screws into the floor of the shed.

Assembling the shed frame

Fit the rest of the walls to the floor of the shed, as shown in the diagram. Drill pilot holes through the bottom plates and insert 3 1/2″ screws into the floor. In addition, lock the adjacent walls together by inserting 2 1/2″ screws through the studs. Make sure the corners are square and check if the edges are flush one with another.

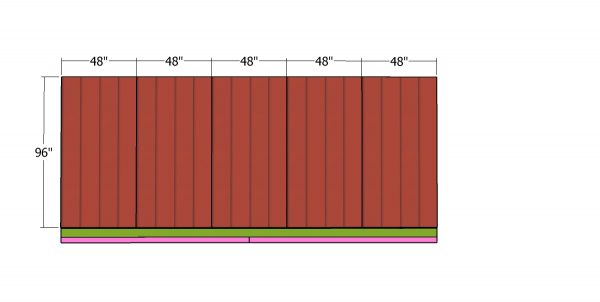

Fitting the siding sheets

Side wall panels

Side wall with door panels

Back wall panels

Front wall panels

Fit the T1-11 sheets to the front wall frame, as shown in the plans. Align everything with attention and lock them into place with 1 5/8″ screws or nails, every 8″ along the framing. Leave no gaps between the siding and the wall frame. In addition, make sure the top edge of the sheets is aligned with the top plates.

Fit the siding to the side walls, making sure you align the sheets properly.

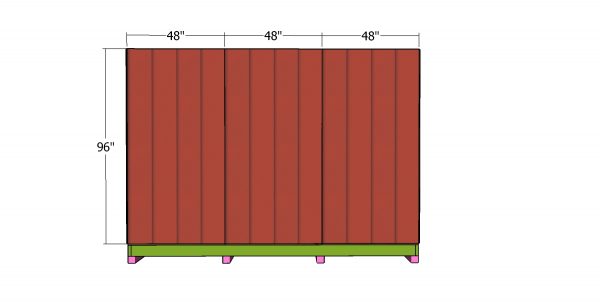

12×20 Shed gambrel Plans dimensions

12×20 Shed gambrel Plans

Last but not least, you should take care of the finishing touches, as to be able to continue the process with the rest of the steps. Fill the holes with wood putty and smooth the surface with fine-grit sandpaper.

12×20 gambrel Shed Plans

Building a 12×20 gambrel shed will cost you roughly $2,500 to $4,000, depending on the quality of materials you go for. Make sure to invest in good timber, sturdy roofing, and solid siding to get the best results. If you fancy adding extras like windows or a loft, pop in an additional $500 to $1,000. It’s all about creating a shed that’s not just functional but also a joy to use!

12×20 barn Shed Plans – front view

Now, let’s focus on the main benefits of building this shed. First, building a 12×20 gambrel shed gives you loads of extra space for storage, keeping everything from tools to garden equipment neatly organized. Second, the unique gambrel roof design not only looks fantastic but also provides additional headroom and potential loft space for even more storage options. Lastly, taking on this project hones your DIY skills and gives you a real sense of accomplishment—you’ll love having a space that’s both practical and something you built with your own hands!

Top Tip: Check out the rest of the project, if you want to learn more about building a roof for the 12×20 shed. Premium Plans available for this shed size, in the Shop. If you want to get PREMIUM PLANS for this project, in a PDF format, please press GET PDF PLANS button bellow. Thank you for the support.

This woodworking project was about 12×20 shed plans. If you want to see more outdoor plans, check out the rest of our step by step projects and follow the instructions to obtain a professional result.