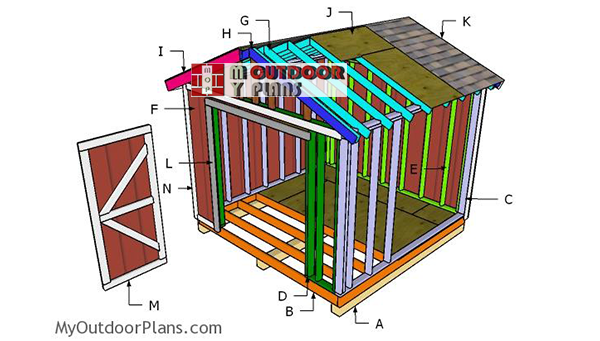

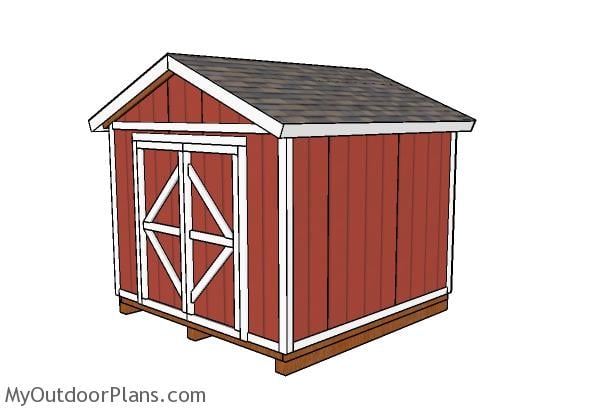

This step by step diy project is about free 10×10 gable shed plans. I have designed this 10×10 gable shed so you can store the garden tools and other small items in a stylish manner. This shed features 7′ tall side walls and a roof with a 22.5 degree slope, making it both easy to build and nice to look at. Take a look over the rest of my woodworking plans, if you want to get more building inspiration. Premium Plans for this shed available in the SHOP.

All my free woodworking plans come with step by step 3D diagrams, instructions, a full cut and shopping list and it is print friendly. As well, the plans are PDF download, so you can take the printed plans with you in the workshop.

When buying the lumber, you should select the planks with great care, making sure they are straight and without any visible flaws (cracks, knots, twists, decay). Investing in cedar or other weather resistant lumber is a good idea, as it will pay off on the long run. Use a spirit level to plumb and align the components, before inserting the galvanized screws, otherwise the project won’t have a symmetrical look. If you have all the materials and tools required for the project, you could get the job done in about a day. See all my Premium Plans HERE.

Projects made from these plans

10×10 Shed Plans

Building-a-10×10-gable-shed

Cut + Shopping Lists

- A – 3 pieces of 6×6 lumber – 10″ long SKIDS

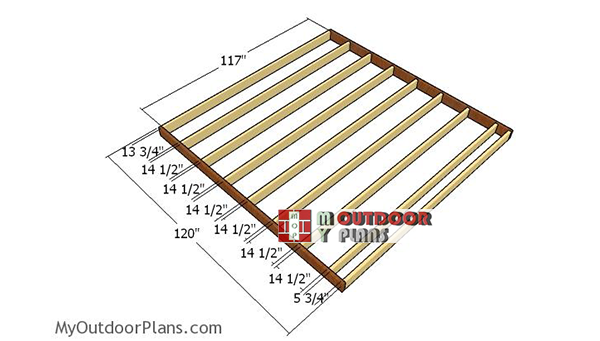

- B – 2 pieces of 2×6 lumber – 120″ long, 9 pieces – 117″long FLOOR

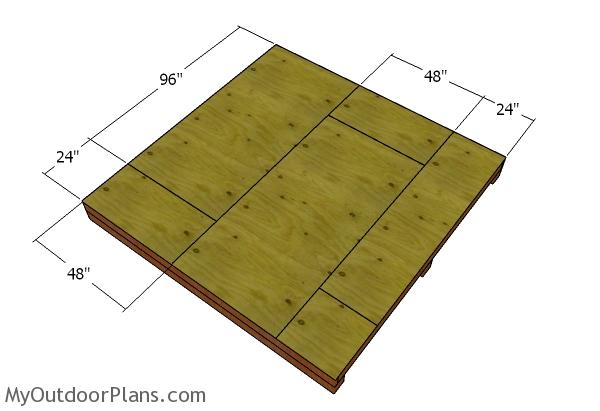

- B – 2 pieces of 3/4″ plywood – 48″x96″ long, 2 pieces – 24″x48″ long, 1 piece – 24″x96″ long, 1 piece – 24″x24″ long FLOORING

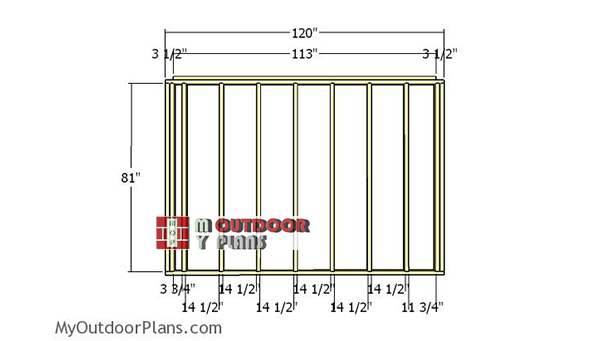

- C – 2 pieces of 2×4 lumber – 120″ long, 1 piece – 113″ long, 11 piece – 81″ long 2xSIDE WALL

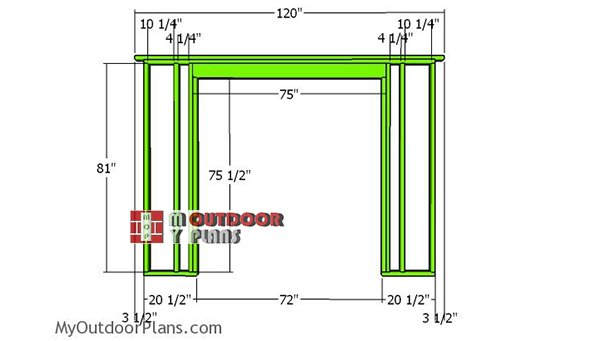

- D – 2 pieces of 2×4 lumber – 20 1/2″ long, 1 piece – 120″ long, 1 piece – 113″ long, 6 pieces – 81″ long, 2 pieces – 75 1/2″ long, 2 pieces of 2×6 lumber – 75″ long FRONT WALL

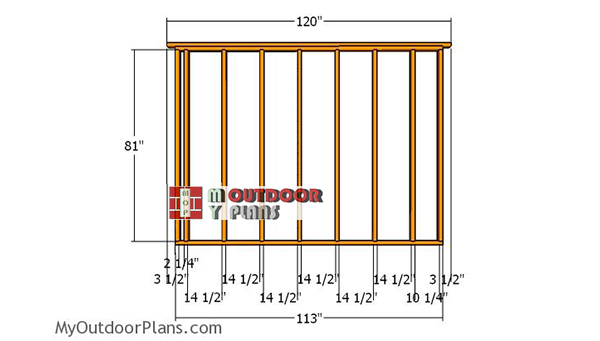

- E – 2 pieces of 2×4 lumber – 120″ long, 2 pieces – 113″ long, 9 pieces – 81″ long BACK WALL

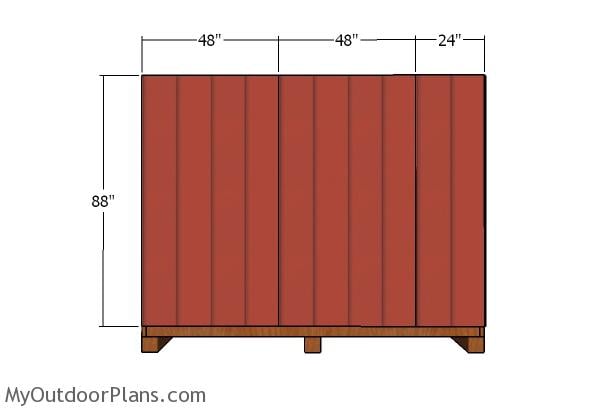

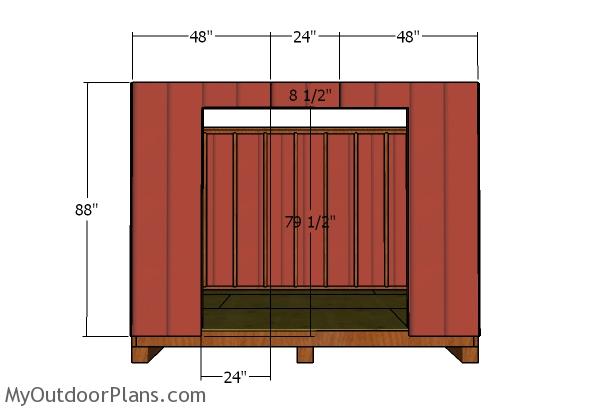

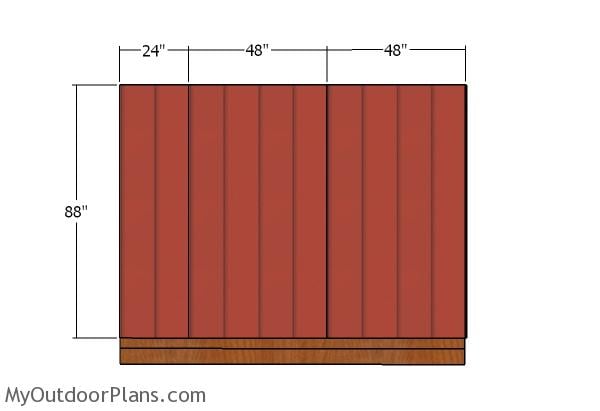

- F – 8 pieces of T1-11 – 48″x88″ long, 3 pieces – 24″x88″ long, 1 piece – 8 1/2″x24″ long SIDING

- 11 pieces of 2×6 lumber – 10′

- 4 pieces of 6×6 lumber – 10′

- 11 pieces of 2×4 lumber – 10′

- 39 pieces of 2×4 lumber – 8′

- 1/2″ plywood

- 2 pieces of 2×6 lumber – 8′

- 3 pieces of 3/4″ plywood – 48″x96″

- 10 pieces of T1-11 – 48″x96″

- 6-8d nails, 1 5/8″ screws, 2 1/2″ screws, 3 1/2″ screws

- wood filler , wood glue, stain/paint

Tools

![]() Hammer, Tape measure, Framing square, Level

Hammer, Tape measure, Framing square, Level

![]() Miter saw, Drill machinery, Screwdriver, Sander

Miter saw, Drill machinery, Screwdriver, Sander

![]() Safety Gloves, Safety Glasses

Safety Gloves, Safety Glasses

Time

Related

- PART 1: 10×10 Shed Plans

- PART 2: 10×10 Shed Roof Plans

- PART 3: 10×10 Shed Door and Trims Plans

- 8×12 Shed Plans

It’s that simple to build a 10×10 Shed – Video!

Step 1: How to build the 10×10 gable shed floor

Building-the-floor-frame

The first step of the project is to build the floor frame. As you can easily notice in the diagram, you need use 2×6 lumber for the joists. Mark the cut lines on the beams and then get the job done with a saw. Smooth the edges flush and then lay them on a level surface.

Place the joists every 16″ on center and make sure the corners are square. Drill pilot holes through the rim joists and then insert 3 1/2″ screws into the perpendicular components.

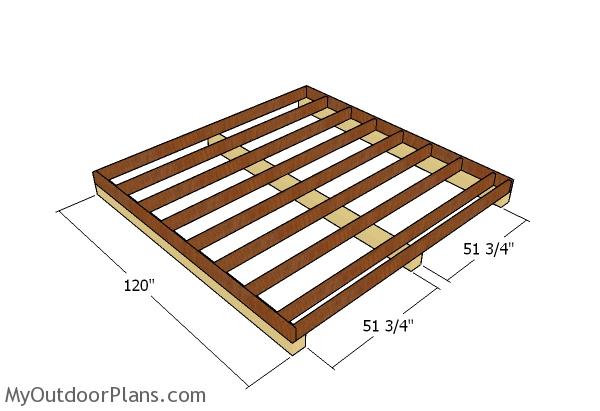

Fitting the skids

Select the location for the backyard shed, making sure you read the local codes and you comply with them. Remove the vegetation layer and then compact a thick layer of gravel. Lay the 4×4 or 6×6 skids on the gravel and then lay the floor frame. Align the edges flush and make sure you lock the frame to the skids with screws or with rafter ties.

Fitting the floor sheets

Lay the 3/4″ plywood sheets to the floor frame, using the pattern shown in the diagram. Drill pilot holes and insert 1 5/8″ screws, every 8″ along the joists. Leave no gaps between the sheets for a professional result.

Step 2: Building the shed wall frames

Side-wall-frame

Continue the project by assembling the wall frames for the shed. Start with the side walls. Cut the components at the right dimensions, using the instructions in the diagram. Drill pilot holes through the plates and insert 3 1/2″ screws into the studs. Place the studs every 16″ on center. Alternatively, you could place the studs every 24″ on center. Fit the double plates into place with 2 1/2″ screws.

Front-wall-frame

Build the front wall for the shed. Make sure you leave 6′ for the door opening, so you can fit the double doors. Use 2×6 lumber and 1/2″ plywood for the double header. Fit the double header to the front frame and then secure it to the studs with 2 1/2″ screws.

Back-wall-frame

Frame the back wall in the same manner described above. Drill pilot holes through the plates and insert 3 1/2″ screws into the studs. Place the studs every 16″ on center for a professional result. Make sure the corners are square and align the edges flush. Place double studs at both ends of the wall, as well.

Assembling the shed frame

Fit the wall frames to the floor of the shed. Align the edges flush and then plumb them with a spirit level. Drill pilot holes through the bottom plates and then insert 3 1/2″ screws to lock them into place tightly. Moreover, you need to lock the adjacent wall together tightly with 2 1/2″ screws. Make sure the corners are square for a professional result.

Step 3: Attaching the wall siding sheets

Back wall – siding

Fit the T1-11 siding sheets to the back of the shed. Align the edges flush and then insert 6-8d nails every 8″ along the framing, so you can lock them into place tightly. Leave no gaps between the sheets for a professional result.

Front wall panels

Side wall panels

Fit the panels to the sides of the shed and align the edges flush. Use 6-8d nails to lock the panels into place tightly, every 8″ along the framing. Leave no gaps between the panels for a professional result.

10×10 Gable Shed Plans – side view

You really need to take a look over PART 2 and PART 3 of the shed project, so you learn how to build the gable roof, the double doors and to learn how to attach the decorative trims.

10×10 Gable Shed Plans

This is a really nice storage shed to have in the backyard, as it features a gable roof, double doors and a lot of storage space. This shed is ideal for any garden as it is compact enough to keep the costs down, while it can add value to the property with its delightful design. Premium Plans for this shed available in the SHOP.

If you want this exact project but in just one PDF file with 1 cut list and 1 shopping list, take a look over the following GET PDF PLANS button.

This woodworking project was about 10×10 garden shed plans free. If you want to see more outdoor plans, check out the rest of our step by step projects and follow the instructions to obtain a professional result.

12 comments

Hello, I’m going to follow your 10×10 shed plan but instead of using 2×6 for the floor joist can I use 2×4?

I don’t recommend that.

I’m interested in building this 10×10 shed. But, I’d like to put in a roll up door like the Janus 650. The opening needs to be at least 6 feet 8 inches tall. The 6 foot width is good.

I need clearance behind the door for the mechanism.

Total width of 6 feet 6 and 3/4 inches.

Total height of 7 feet 11 and 1/2 inches.

It looks to me like I could just make the 2×4 studs in the walls 84 inches tall instead of 81. This would make the opening 80 inches tall instead of 77 inches. I could then cut the siding sheets to a height of 91 inches instead of 88.

This would also make the height inside the building at the sides of the door about 97 inches which gives me room for the door mechanism.

Any potential problems with this?

No, the techniques are the same so you can adjust the size of the studs to your needs. Just make sure you comply with the local codes.

Do you have these plans in Spanish?

No

This is a great plan! I have built it mostly now. There is an are where critters can get in, under where the roof overhangs the walls (under the trusses). How would you suggest sealing this off? Metal vented soffit?

Congrats on your build. Yes, that or 1/4″ plywood.

In your instructions, you mentioned 1 5/8 inch screws but your shopping list doesn’t include that. Is this an oversight?

Also I didn’t see a one shopping list one PDF option for the 10×10 gable shed on your other site for purchase.

Do you need to use pressure treated boards for the floor joists or the plywood you lay down on the floor?

It looks like your spacing is off for the wall framing. On the side walls, the measurement adds up to 119″ instead of 120′, and with the way things are spaced on the side and back walls, your 48″ T1-11 panels wouldn’t land on studs when you’re nailing them down.

Everything is accurate. You didn’t account for the 1/2″ gaps between the double studs. That’s why you have 3 1/2″ recess for the top double plate.