This step by step diy woodworking project is about a 15×12 garden gable pavilion plans. This gazebo has a gable roof and it features just 4 posts, so you get large openings on all sides. In addition, the garden pavilion has large overhangs on all sides. Make sure you take a look over the local building codes, so you comply with the regulations. Take a look over the rest of our woodworking plans, if you want to get more building inspiration. Check out the Shop, as well, for full list of Premium Plans.

When buying the lumber, you should select the planks with great care, making sure they are straight and without any visible flaws (cracks, knots, twists, decay). Investing in cedar or other weather resistant lumber is a good idea, as it will pay off on the long run. Use a spirit level to plumb and align the components, before inserting the galvanized screws, otherwise the project won’t have a symmetrical look. If you have all the materials and tools required for the project, you could get the job done in about a day. See all my Premium Plans HERE.

Projects made from these plans

15×12 Garden Gable Pavilion Plans

Building-a-15×12-gable-pavilion

Cut + Shopping Lists

A – 4 pieces of 6×6 lumber – 8 ft POSTS

B – 2 pieces of 6×8 lumber – 14 ft SIDE TOP BEAMS

C – 2 pieces of 6×8 lumber – 15 ft CROSSBEAMS

D – 2 pieces of 6×6 lumber – 36 3/8”, 1 piece of 6×8 lumber– 14 ft RIDGE BEAMS

E – 10 pieces of 6×6 lumber – 42” BRACES

F – 14 pieces of 2×6 lumber – 120” RAFTERS

G – 4 pieces of 3/4” plywood – 4’x8’, 2 pieces – 4’x4’, 2 pieces – 4’x6’, 2 pieces – 2’x4’, 2 pieces – 2’x8’, 2 pieces – 2’x6’ ROOF SHEETS

H – 2 pieces of 1×8 lumber – 14’, 4 pieces – 121 1/8” ROOF TRIMS

I – 350 ft of tar paper, 350 ft of asphalt shingles ROOFING

Tools

![]() Hammer, Tape measure, Framing square, Level

Hammer, Tape measure, Framing square, Level

![]() Miter saw, Drill machinery, Screwdriver, Sander

Miter saw, Drill machinery, Screwdriver, Sander

Time

Related

- PART 1: 15×12 Pavilion Plans

- PART 2: 15×12 Pavilion Roof Plans

It’s that easy to build a gable pavilion!

How to build a 15×12 pavilion – laying out

Laying-out-the-posts

First, layout the posts for the 15×12 gable pavilion. Use batter boards and string to determine the location of the posts. Apply the 3-4-5 rule to every corner of the pavilion, so you make sure they are right angled. Make sure the diagonals are equal and make adjustments if necessarily.

Determining the location for the pavilion is essential, as you have to comply with the local building codes. Make sure the surface is level and remove the vegetation layer. If you want a concrete slab, you should take that into account before setting the posts (leave enough clearance).

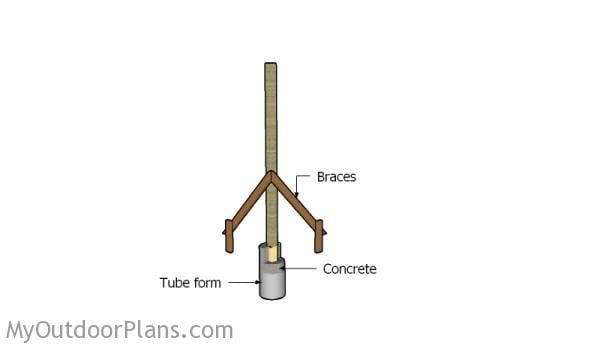

Setting the posts in concrete

Dig 3 ft holes into the ground, making sure they have about 12-14″ in diameter. Fit the tubes then the posts into the ground and plumb them with a spirit level. Use temporarily braces to make sure the posts are locked into placed while filling the holes with concrete. Let the concrete dry out for several days. Read the local codes for more details on how to secure the posts.

Use lag screws to secure the posts to the anchors. Before pouring the concrete you need to make sure the top of the posts are horizontal one to another. Use a laser to mark the level to the top of the posts and use a circular saw, if you need to make cuts.

Building the frame of the large pavilion

Top-plates

For this project we will be using 6×8 lumber for the rails. Mark the cut lines on the beams and then make the cut outs with a circular saw and a chisel. Smooth the surface with sandpaper. Use 6×8 lumber for the other rails. Set the circular saw at 3 5/8″ and then make parallel cuts inside the marked areas.

Clean the recess with a chisel, a hammer and sandpaper. You need 2 pieces for the side top plates and 2 pieces for the crossbeams.

Read the local codes to make sure the 6×8 beams are appropriate for your location.

Attaching-the-top-side-plates

Fit the 6×8 top rails to the sides of the pavilion. Notice the 12″ overhangs to the front and back of the pavilion. Drill pilot holes through the plates and insert 8″ screws to lock them to the posts. Use 2 screws for each joint. Make sure the corners are square and plumb the posts vertically.

The beams are heavy so most likely you will need the help of another pair of hands, so you can lift them and place them into place.

Fitting-the-crossbeams

Fit the cross plates to the pavilion. Align the edges flush and drill pilot holes. Insert the 8″ screws to lock the cross plates into place tightly.

Fitting-the-braces

Build the braces for the front and back of the pavilion from 6×6 lumber. Use a miter saw to make 45 degree cuts to both ends of the braces. Fit the braces to the posts, after you plumb them vertically.

Drill pilot holes and insert 5 1/2″ screws to secure the braces into place tightly. Insert 2 screws for each joint. The braces will reinforce the rigidity of the pavilion and prevent lateral movements due to wind.

Remember that you still need to keep the temporarily braces into place, until all structure is installed, because they add rigidity to the pavilion.

Building the roof of the pavilion

Fitting-the-ridge-beam-supports

Center the 6×6 supports to the top of pavilion. Plumb the supports with a spirit level. Use post to beam connectors and 2 1/2″ structural screws to secure the supports to the frame of the pavilion.

Remember that the height for this posts is designed for a corresponding 6:12 pitch. If you want a different pitch for your project you need to start by changing the height of these supports.

Fitting-the-ridge-beam

Fit the 6×8 ridge beam to the supports with post to beam connectors. Make sure the corners are square. Notice the 12″ overhangs to the front and back, similar to the side plates. Use 2 1/2″ structural screws to lock the connectors into place.

Ridge-beam-braces

Use 6×6 lumber for the braces. Make 45 degree cuts at both ends of the braces. Secure the braces into place with 5 1/2″ screws. Drill pilot holes before inserting the screws. As usual, use 2 screws for each joint.

Finishing touches

15×12-pavilion—overall-dimensions

Check out PART 2 of the project to learn how to build the gable roof. See the overall dimensions of this pavilion in the image above.

15×12 gable pavilion

Fill the holes with wood putty and let them dry out for a few hours. Smooth the surface with 100-220 grit sandpaper and remove the residues with a damp cloth.

This gable pavilion is the perfect project for your backyard and the ideal addition to your BBQ cooking area. The simple design with straight lines and harmonious proportions will please the eye and add value to your property. Additionally, the roof is made out of 3/4″ plywood and asphalt shingles, to keep the costs down and protect the structure from the elements.

Top Tip: Apply a few coats of paint or stain to the components, to enhance the look of the project. Premium Plans for this project available Here. Check out the Shop, as well, for full list of Premium Plans. Press the GET PDF PLANS button bellow, if you want to get the Premium Plans with the full Cut and Shopping lists included, as well as with the cut layout diagram.

This woodworking project was about 15×12 gable pavilion plans. If you want to see more outdoor plans, check out the rest of our step by step projects and follow the instructions to obtain a professional result.

1 comment

Hey, I’m having trouble finding 6×8 lumber for this plan. Do you know if we used 6×6 in place of the 6×8 if this would change the angle of the roof or if the cut plans for the rafters would still be accurate? The rails and ridge beam are both 6×8. Thank you