This step by step diy project is about free 10×12 run in shed plans. I have designed this small run in horse shelter so you can build it in a few days with basic tools and materials. This shed has a run in front wall and three plain walls. You can adjust the slope of the roof to suit your needs. Take a look over the rest of my woodworking plans, if you want to get more building inspiration. Roof pitch is 3:12.

When buying the lumber, you should select the planks with great care, making sure they are straight and without any visible flaws (cracks, knots, twists, decay). Investing in cedar or other weather resistant lumber is a good idea, as it will pay off on the long run. Use a spirit level to plumb and align the components, before inserting the galvanized screws, otherwise the project won’t have a symmetrical look. If you have all the materials and tools required for the project, you could get the job done in about a day. See all my Premium Plans HERE.

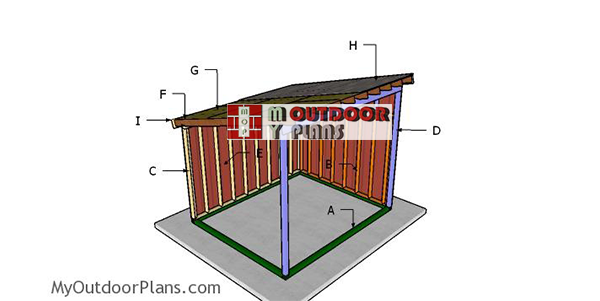

10×12 Run In Horse Shelter Plans

Building-a-10×12-horse-shed

Cut List

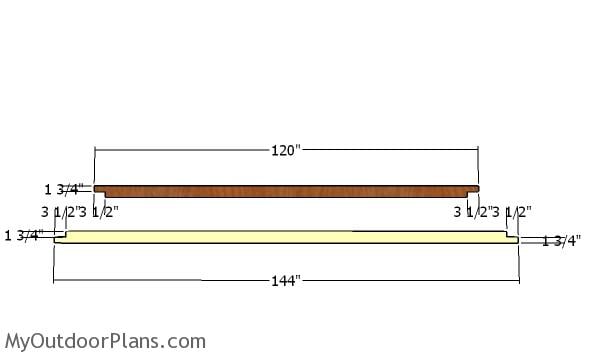

- A – 2 pieces of 4×4 lumber – 120″ long, 2 pieces – 144″ long BASE

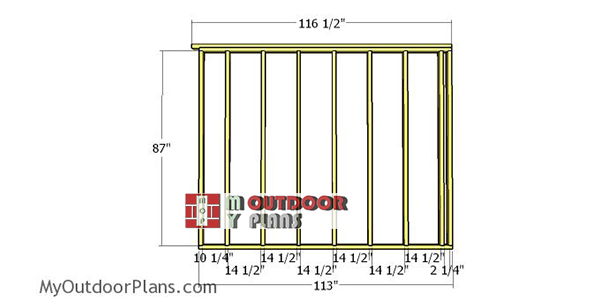

- B – 2 pieces of 2×4 lumber – 113″ long, 1 piece – 116 1/2″ long, 9 pieces – 87″ long 2xSIDE WALL

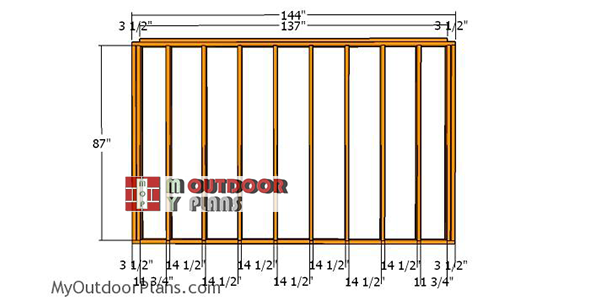

- C – 2 pieces of 2×4 lumber – 144″ long, 1 piece – 137″ long, 12 pieces – 87″ long BACK WALL

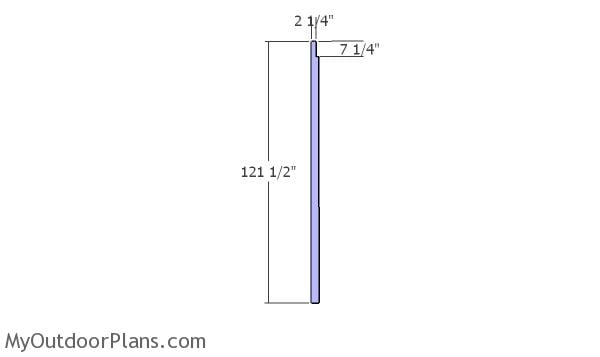

- D – 2 pieces of 4×4 lumber – 121 1/2″ long POST

- E – 1 piece of 2×8 lumber – 144″ long SUPPORT BEAM

Shopping List

- 2 pieces of 4×4 lumber – 10′

- 4 pieces of 4×4 lumber – 12″

- 3 pieces of 2×4 lumber – 12′

- 6 pieces of 2×4 lumber – 10′

- 30 pieces of 2×4 lumber – 8′

- 1 piece of 2×8 lumber – 12′

- 2 1/2″ screws, 3 1/2″ screws, 1 5/8″ screws

- 4″ carriage bolts

- 4d nails

- hurricane ties

- wood filler , wood glue, stain/paint

Tools

![]() Hammer, Tape measure, Framing square, Level

Hammer, Tape measure, Framing square, Level

![]() Miter saw, Drill machinery, Screwdriver, Sander

Miter saw, Drill machinery, Screwdriver, Sander

![]() Safety Gloves, Safety Glasses

Safety Gloves, Safety Glasses

Time

Related

- PART 1: 10×12 Run in shed plans

- PART 2: 10×12 Run in roof shed plans

- 10×12 Field shed plans

- 10×16 Horse barn with tack room plans

Building a 10×12 run in shed

Base components

The first step of the project is to build the beams for the base of the shed using 4×4 lumber. Cut both ends of the beams, as shown in the diagram. Make parallel cuts to the indicated areas and then remove the excess with a chisel. Smooth the surface with sandpaper.

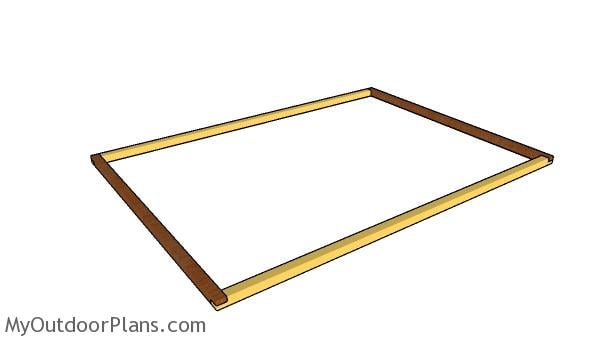

Assembling the base of the shed

Select the location for the shed and then remove the vegetation layer. Level the surface with a spirit level and then fit the 4×4 pressure treated beams into place. Assemble the base for the shed using 3 1/2″ screws. Make sure the corners are square, drill pilot holes and then insert the screws to lock the base beams together tightly.

Use 2×3 anchors to lock the base into the ground, every 16″. Alternatively, use hurricane anchors if you live an area with strong winds.

Building the shed walls

Back-wall-frame

The next step of the project is to build the back wall from 2×4 lumber. Cut all the components at the right dimensions, after taking accurate measurements. Make sure the edges are flush and check if the corners are square. Drill pilot holes through the plates and insert 3 1/2″ screws into the studs. Place double studs at both ends of the wall, with 1/2″ plywood between them. Fit the studs every 16″ on center.

Side-wall-frame

Build the side walls for the run in shed. Cut the components at the right dimensions and then assemble the frames using the same techniques described above.

Building the posts

Use 4×4 lumber for the front posts. Mark the cut lines on the top of the posts and then get the job done with a circular saw. Make 1 1/2″ deep parallel cuts inside the marked area and then get the job done with a chisel. Smooth the recess with sandpaper, for a professional result.

Fitting-the-top-beam—10×12-shed

Attach the walls to the base with 3 1/2″ screws. Drill pilot holes through the bottom plates and insert 3 1/2″ screws into the base beams. Use a spirit level to plumb the posts vertically and then check if the corners are square. Align everything with attention for a professional result.

Fit the posts to the front of the shed. Align the edges with attention and then drill pilot holes. Insert 5″ screws to lock them to the side wall properly. Use a spirit level to plumb the posts properly. Fit the 2×8 support beam to the top of the posts. Make sure the corners are square and align the edges with attention. Drill pilot through the beam and posts and then insert 4″ carriage bolts. Use at least 3 bolts for each side.

10×12 Run In Horse Shelter Plans

This 10×12 loafing shed is easy to build and it can shelter a different variety of items. You can make modifications to my design to suit your needs.

10×12 Run In Horse Shelter Plans – Front view

This is a simple project you should be able to build in a few days without much effort. This 10×12 run in shed is a multi purpose shelter. You can use this run in shed for storing tools, equipment or even outdoor furniture.

10×12 Run In Horse Shelter – dimensions

Building a 10×12 run-in shed with a gable roof will likely cost you between $1,500 and $2,500, depending on the materials and finishes you choose. The gable roof offers both durability and a classic look, while the open-front design of the run-in shed provides easy access for animals or equipment. This investment creates a sturdy, functional shelter that’s perfect for livestock or storage, combining practicality with a touch of style.

10×12 Run in shed – free plans

You’re looking at about 2 to 4 weekends to complete your 10×12 run-in shed with a gable roof. The build is straightforward, but ensuring that the structure is solid and weather-resistant will require careful attention to detail. With consistent progress, you’ll have a well-built, reliable shelter ready to serve its purpose.

Check out PART 2 of the project to learn more on how to build the roof for the shed. If you want to get this project as a PDF file with 1 full Cut list and 1 full Shopping list, please take a look over the GET PDF PLANS button bellow.

This woodworking project was about run in shed plans free. If you want to see more outdoor plans, check out the rest of our step by step projects and follow the instructions to obtain a professional result.

6 comments

I was wondering if you could possibly make this lean to with materials that are more farm animal friendly the t1-11 siding is not worth spending over $400 to get beat up out in the pasture, if you know what I mean. I was also wondering if you could go into more detail on each step it does get a bit confusing, I love the lean to it is perfect for my horse I just can’t use the materials. Thanks!

Hi there, what steps do you need more assistance with? Regarding the materials, you can replace the T1-11 siding with OSB, Plywood or 1×6 slats. Choose what suits your budget.

Nice plans, I’m 75% done with my project. I changed the roof to metal and plan to line the interior with old 2×4’s to add strength and give the run in a custom look.

That sounds great. Good luck with the project and let me know how it comes out. I would love to feature your project on the blog. You can send a few pics here: http://myoutdoorplans.com/contact/

Would you be able to tell me how much tin would be needed if I substituted tin for the T1-11? I would be using tin for siding and roof.

I have a question about the side walls for this project. The measurements are confusing on the diagram. It is hard to tell where they measurements are from and to. We completed the back wall with no issues. Where are each of the measurements from and to? Is there any way to indicate what the exact measurements are from what is the back to the front? For example, the first measurement would be 1.5 inches that is where the end stud goes. Then there appears to be a space between the end stud and the next one, what is the measurement for the next stud, from the end of the bottom plate? What is the measurement for the next stud from the end of the bottom plate? Thanks in advance.