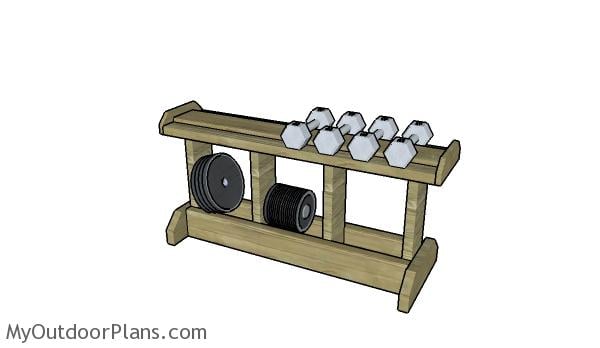

This step by step diy project is about farmhouse dining table plans. I have designed this weight rack so you can organize better your gym room. I have spend a lot of time optimizing the size of the rack, so you can make most of the space and materials. Even if you are a beginner when it comes to woodworking, you shouldn’t face issues when building the rack. Take a look over the rest of our woodworking plans, if you want to get more building inspiration.

When buying the lumber, you should select the planks with great care, making sure they are straight and without any visible flaws (cracks, knots, twists, decay). Investing in cedar or other weather resistant lumber is a good idea, as it will pay off on the long run. Use a spirit level to plumb and align the components, before inserting the galvanized screws, otherwise the project won’t have a symmetrical look. If you have all the materials and tools required for the project, you could get the job done in about a day.

Projects made from these plans

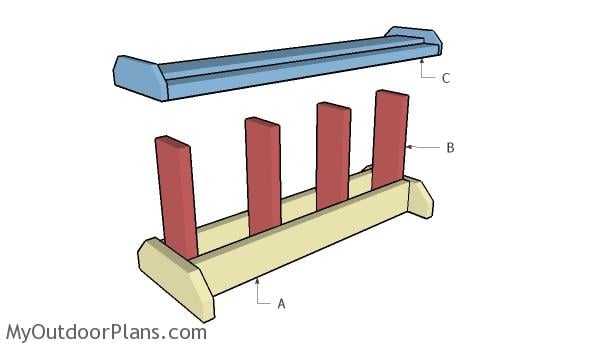

Weight Rack Plans

Building a weight bench

Cut & Shopping Lists

- A – 2 pieces of 2×6 lumber – 42″ long, 2 pieces – 16 1/2″ long BASE

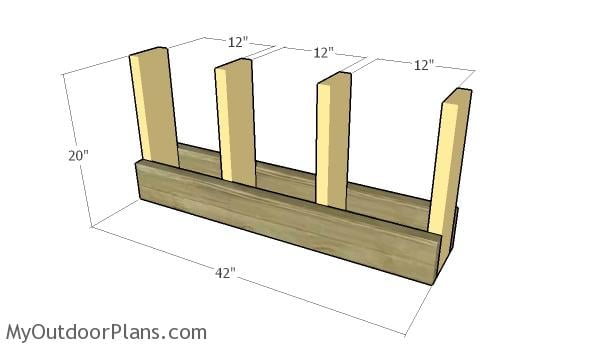

- B – 4 pieces of 2×6 lumber – 20″ long SUPPORTS

- C – 1 piece of 2×12 lumber – 46 1/2″ long, 1 piece of 1×6 lumber – 46 1/2″ long, 2 pieces of 1×4 lumber – 11 1/4″ long TOP

- 2 pieces of 2×6 lumber – 10′

- 1 piece of of 2×12 lumber – 6′

- 1 piece of 1×6 lumber – 6′

- 2 pieces of 1×4 lumber – 6′

- 100 pieces of 2 1/2″ screws

- 2″ brad nails

- wood glue, stain/paint

- wood filler

Tools

![]() Hammer, Tape measure, Framing square, Level

Hammer, Tape measure, Framing square, Level

![]() Miter saw, Drill machinery, Screwdriver, Sander

Miter saw, Drill machinery, Screwdriver, Sander

Time

Related

Building a wooden weight rack

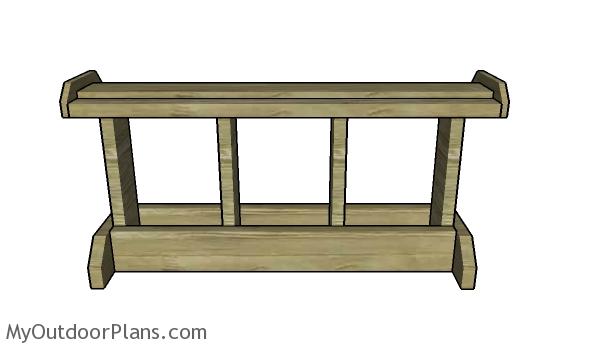

Assembling the frame of the rack

The first step of the project is to assemble the frame of the weight rack. Cut the components from 2×6 lumber and align the edges with attention. Make sure the corners are square and use a spirit level to check if the supports are plumb. Drill pilot holes through the horizontal braces and insert 2 1/2″ screws into the vertical supports. Add waterproof glue to the joints and remove the excess with a damp cloth.

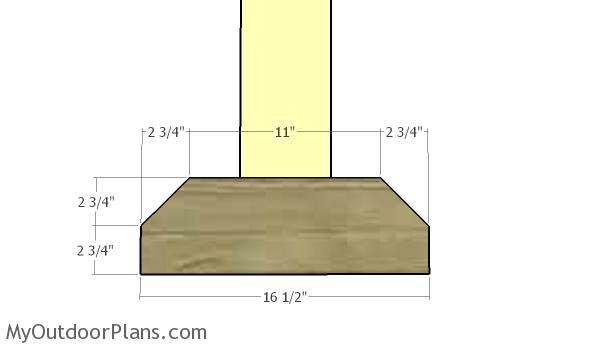

Fitting the base supports

Build the base from 2×6 lumber, as well. Make decorative cuts to the exposed corners of the base and secure them to the frame of the weight rack using 2 1/2″ screws. Add glue to the joints and leave no gaps between the components.

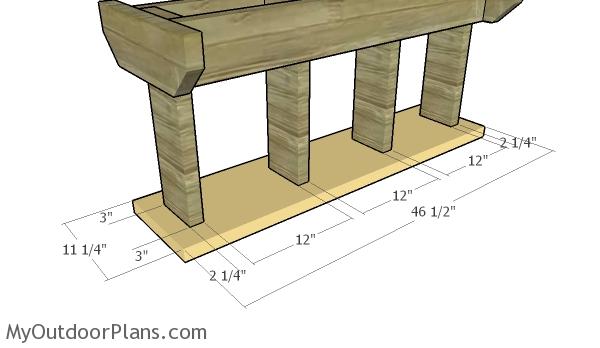

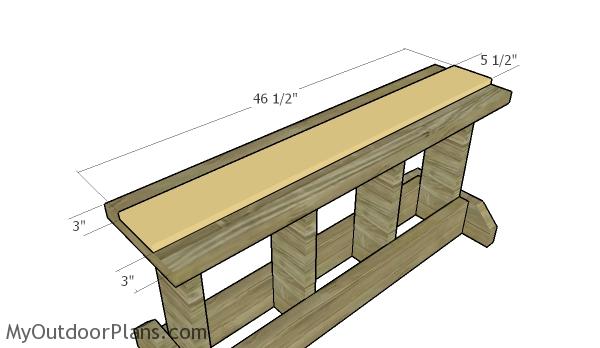

Attaching the top

The next step of the project is to attach the 2×12 top to the frame. You can drill pocket holes along the top of the vertical supports and insert 2 1/2″ screws into the top, or you can drill pilot holes through the top and insert 2 1/2″ screws into the supports. Add glue to the joints and center the supports to the top, as shown in the diagram.

Fitting the top support

Attach a piece of 1×6 lumber to the top of the rack, as shown in the diagram. This slat will prevent the weight from slipping off the top. Center the 1×6 slat to the top, add glue to the joints and insert 2″ brad nails to secure it into place. You might have to adjust the width of the slat, so your weights fit into place.

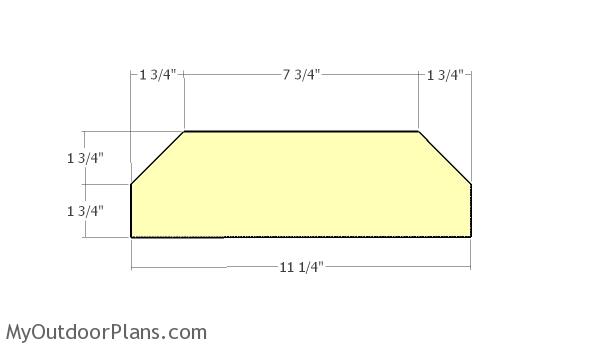

Building the sides

Build the ends for the weight rack from 1×4 lumber. Make decorative cuts to the exposed corners of the slats and smooth the edges with sandpaper.

Fitting the sides

Attach the side slats to the top of the weight rack. Align the edges, add glue to the joints and insert 2″ brad nails to secure the components into place. Leave no gaps between the components for a professional result.

How to build a weight rack

Once you have assembled the weight rack, you need to take care of the finishing touches. Use 120-220 sandpaper to smooth the surface. Drill the holes and dents with wood putty and let it harden for a few hours. Smooth the surface with sandpaper.

Weight Rack Plans

Apply a few coats of stain to enhance the look of the project and to protect the wood from decay. This is a super simple project anyone should be able to build in a few hours without much effort. Remember that you need to adjust the size of the components so they suit your particular own needs. The size of the weights differ, so you might have to make adjustments.

This woodworking project was about weight rack plans free. If you want to see more outdoor plans, check out the rest of our step by step projects and follow the instructions to obtain a professional result.