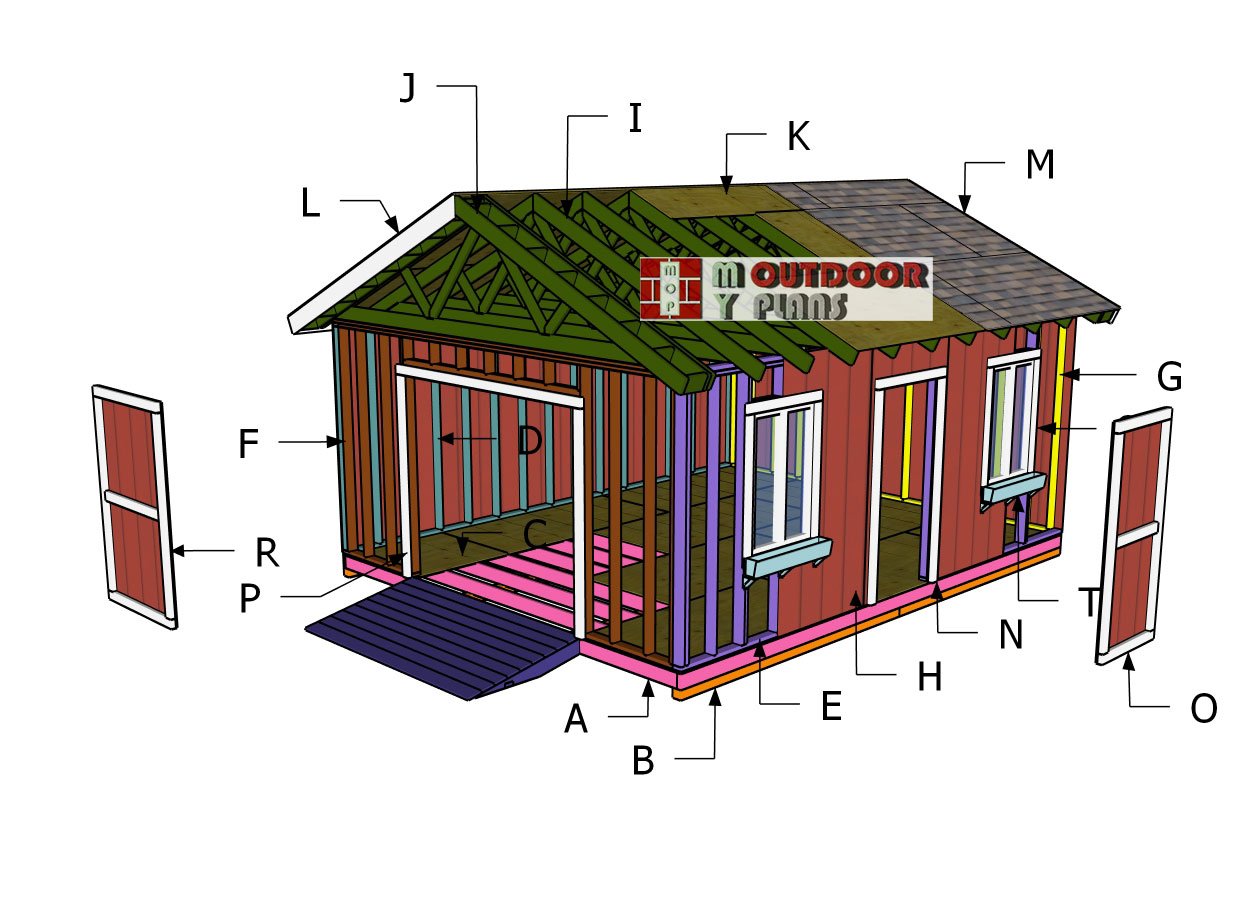

Welcome to Part 2 of our 16×20 gable shed build! Now that we’ve completed the main framework, it’s time to dive into the exciting details that will turn this sturdy structure into a fully functional and weather-resistant shed. In this phase, we’ll tackle the overhangs, a crucial feature that not only enhances the shed’s appearance but also provides extra protection against rain and sun. I’ll guide you through building these overhangs step by step to ensure a seamless fit that blends perfectly with the shed’s gable design. We’ll also cover the roofing process, where you’ll learn how to install durable materials that shield your shed from the elements while adding a sleek, finished look.

But that’s not all, this part also focuses on crafting and installing the double front doors and the side door, essential for accessibility and style. These doors are designed to be sturdy, functional, and aesthetically pleasing, and I’ll show you how to build them with precision and care. Whether you’re aiming to store tools, create a workshop, or have a versatile backyard space, this section brings all the practical and aesthetic elements together. By the end of Part 2, your shed will be ready to stand strong and proud in your backyard, fully equipped for whatever you plan to use it for.

When buying the lumber, you should select the planks with great care, making sure they are straight and without any visible flaws (cracks, knots, twists, decay). Investing in cedar or other weather resistant lumber is a good idea, as it will pay off on the long run. Use a spirit level to plumb and align the components, before inserting the galvanized screws, otherwise the project won’t have a symmetrical look. If you have all the materials and tools required for the project, you could get the job done in about a day. See all my Premium Plans HERE.

Projects made from these plans

16×20 Gable Shed Plans – PDF Download

Building-a-16×20-gable-shed

Cut & Shopping Lists

- H – SIDING – 5/8″ T1-11 siding 4’x’8′ – 16 pieces

- H – SIDING – 5/8″ T1-11 siding 4’x’16” – 2 pieces

- H – SIDING – 5/8″ T1-11 siding 4’x’29 1/2″ – 4 pieces

- H – SIDING – 5/8″ T1-11 siding 4’x’52” – 4 pieces

- J – OVERHNAGS – 2×6 lumber 119 1/8″ – 8 pieces

- J – OVERHNAGS – 2×6 lumber 8 1/2″ – 36 pieces

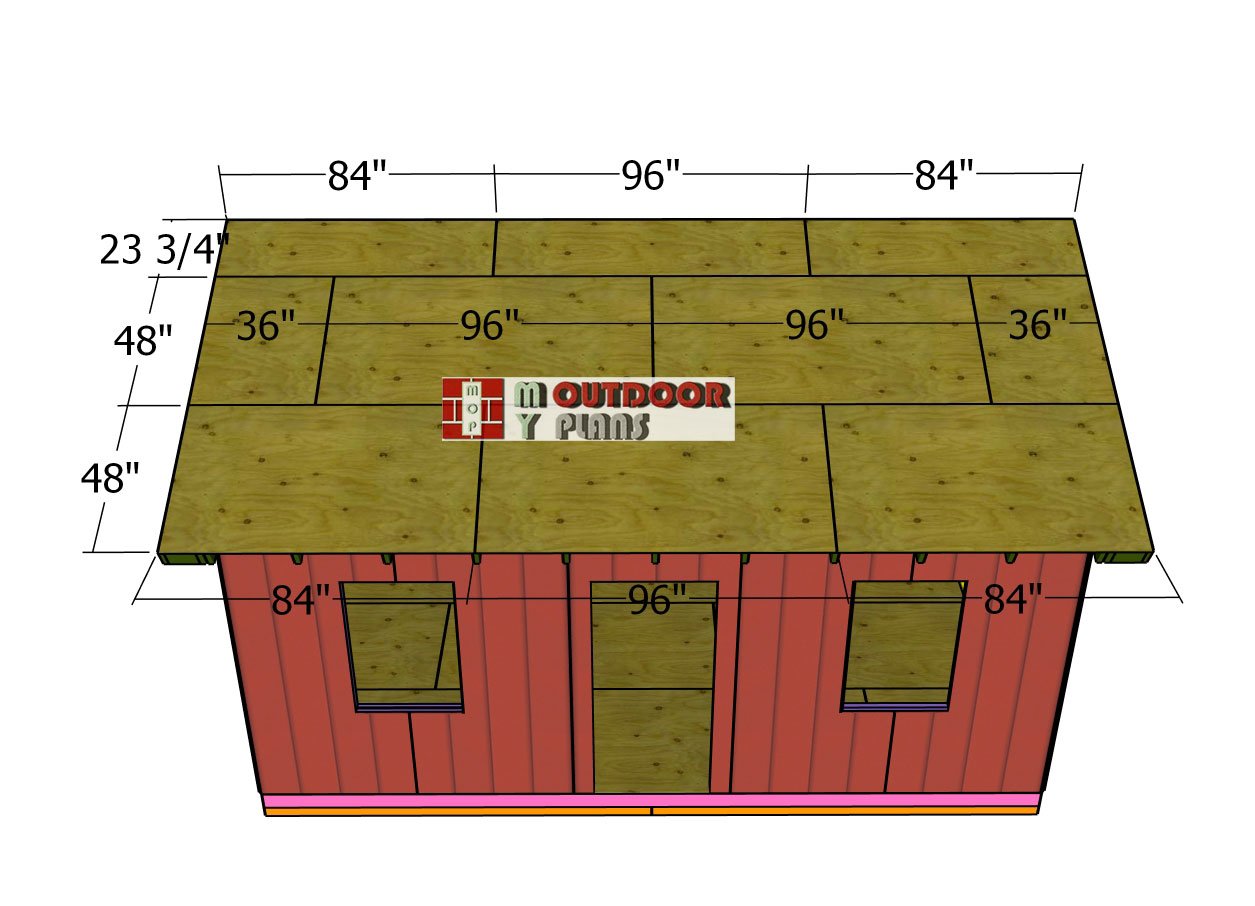

- K – ROOF SHEET – 3/4″ plywood 4’x8′ – 6 pieces

- K – ROOF SHEET – 3/4″ plywood 4’x7′ – 4 pieces

- K – ROOF SHEET – 3/4″ plywood 4’x3′ – 4 pieces

- K – ROOF SHEET – 3/4″ plywood 23 1/4’x7′ – 4 pieces

- K – ROOF SHEET – 3/4″ plywood 23 1/4’x8′ – 2 pieces

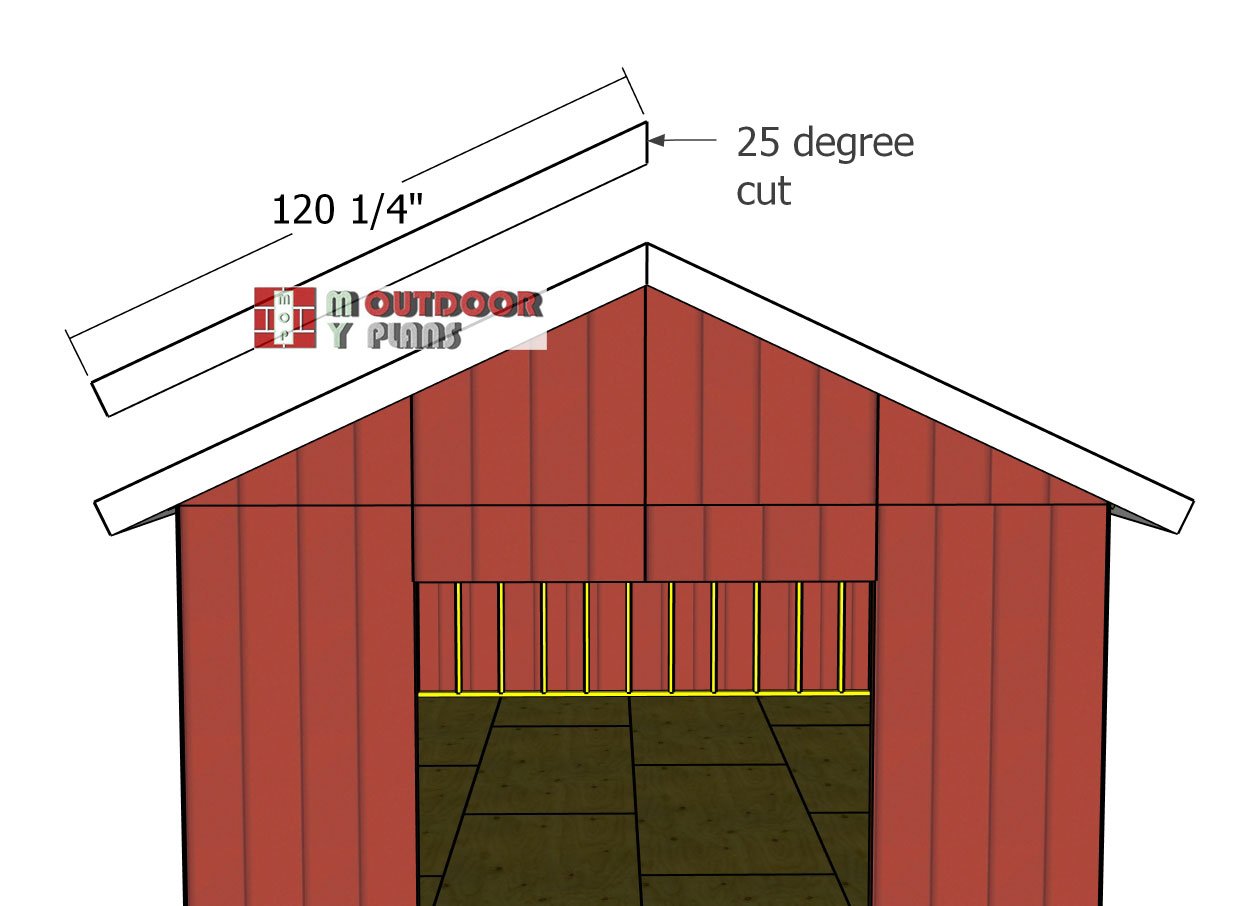

- L – ROOF TRIMS – 1×8 lumber 120 1/4″ – 4 pieces

- L – ROOF TRIMS – 1×8 lumber 132″ – 4 pieces

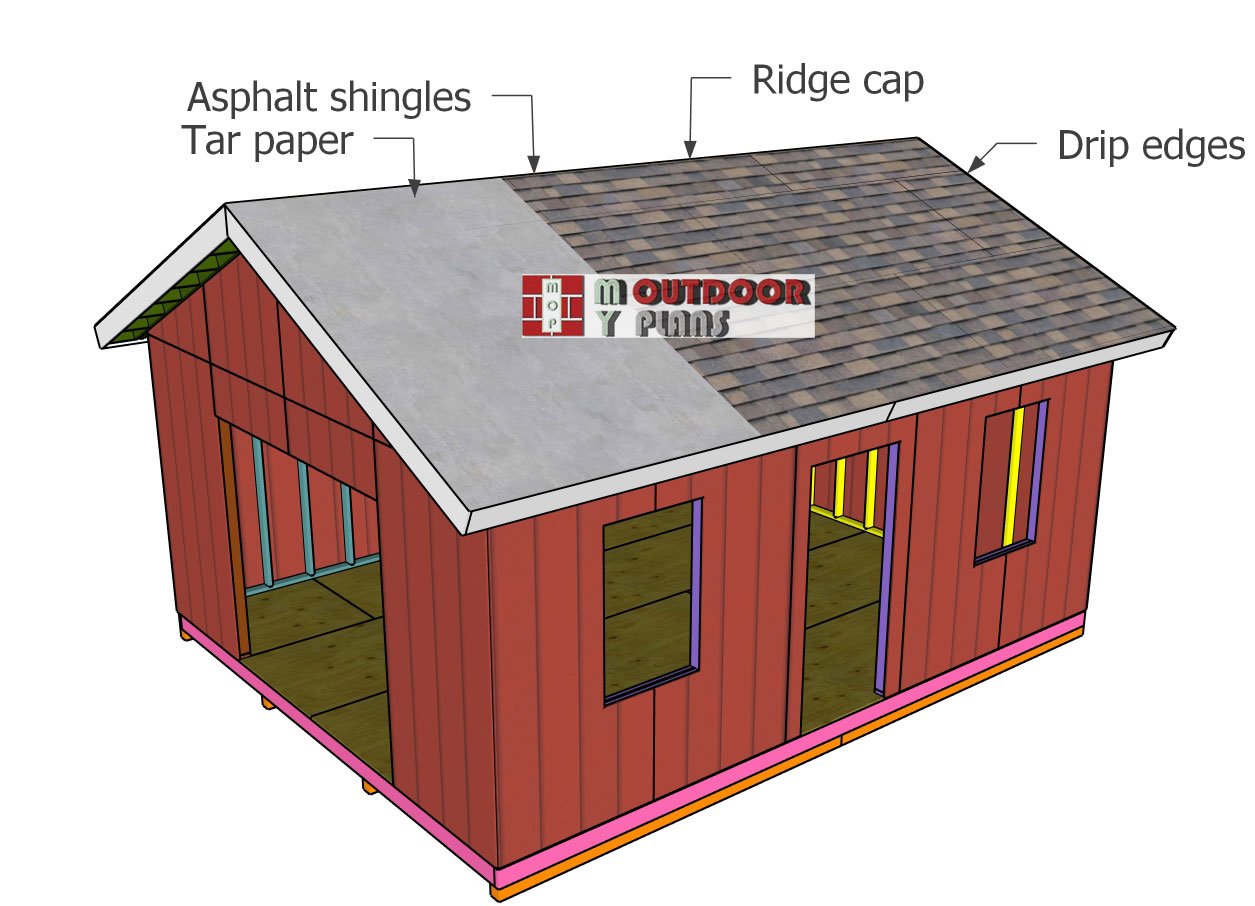

- M – ROOFING – tar paper & asphalt shingles – 500 sq ft

- N – JAMBS – 2×4 lumber 80″ – 2 pieces

- N – JAMBS – 2×4 lumber 43″ – 1 piece

- O – DOOR FRAME – 2×4 lumber 36″ – 2 pieces

- O – DOOR FRAME – 2×4 lumber 29″ – 1 piece

- O – DOOR FRAME – 2×4 lumber 73″ – 2 pieces

- P – JAMBS – 2×4 lumber 80″ – 2 pieces

- P – JAMBS – 2×4 lumber 103″ – 1 piece

- R – DOOR – 2×4 lumber 73″ – 4 pieces

- R – DOOR – 2×4 lumber 48″ – 4 pieces

- R – DOOR – 2×4 lumber 41″ – 2 pieces

Tools

![]() Hammer, Tape measure, Framing square, Level

Hammer, Tape measure, Framing square, Level

![]() Miter saw, Drill machinery, Screwdriver, Sander

Miter saw, Drill machinery, Screwdriver, Sander

![]() Safety Gloves, Safety Glasses

Safety Gloves, Safety Glasses

Time

Related

- 6×8 Lean to Shed Plans

- 16×20 Gable Shed Plans – Part 1

- 16×20 Gable Shed Plans – Part 2

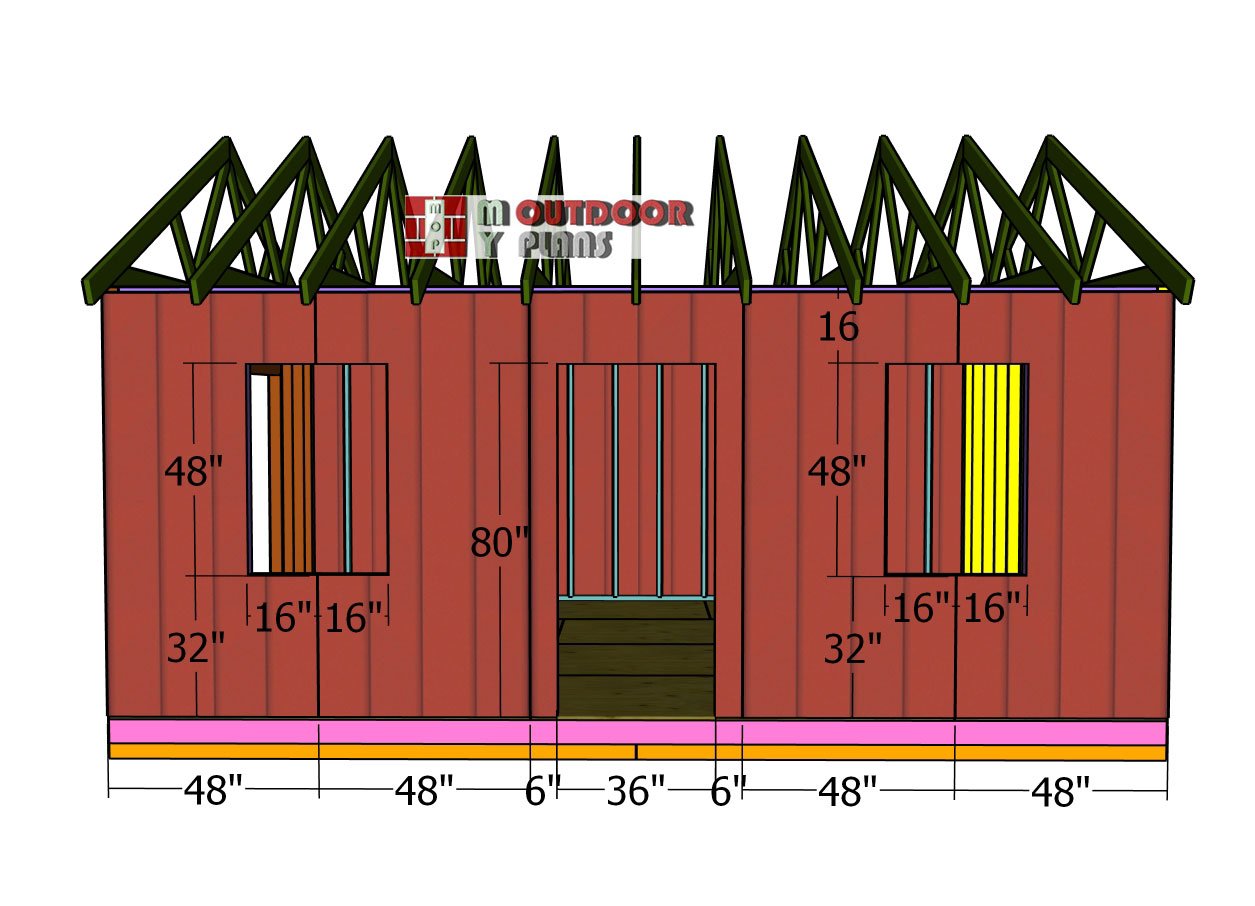

Step 3: Fitting the siding

Side-wall-panels

Attach the 5/8″ T1-11 siding sheets to the side walls of the shed, starting at one corner and working your way across. For the side with window and door openings, carefully measure and mark the cutouts, ensuring accuracy, as the door cutout will double as the door panel.

Use a circular saw to make precise cuts, and remember to measure twice before cutting to avoid mistakes. Align the edges of the siding flush with the wall framing, leaving no gaps between the panels for a seamless look. Secure the siding with 8d nails, spacing them every 8 inches along the framing to ensure the panels are firmly attached and can withstand the elements. This step not only protects the shed but also gives it a polished, professional appearance.

Side-wall-panels

Attach the siding sheets to the front of the shed, aligning the edges flush with the wall frame for a clean, even fit. Carefully measure and mark the door opening on the siding, then use a circular saw to cut out the section. Take your time with the cuts, as precision is key for a professional finish.

Once the panels are properly trimmed, position them on the wall and secure them using 8d nails, driving the nails every 8 inches along the framing. Ensure the panels are tightly fitted with no gaps, as this step will not only protect your shed from the elements but also prepare the surface for the final touches.

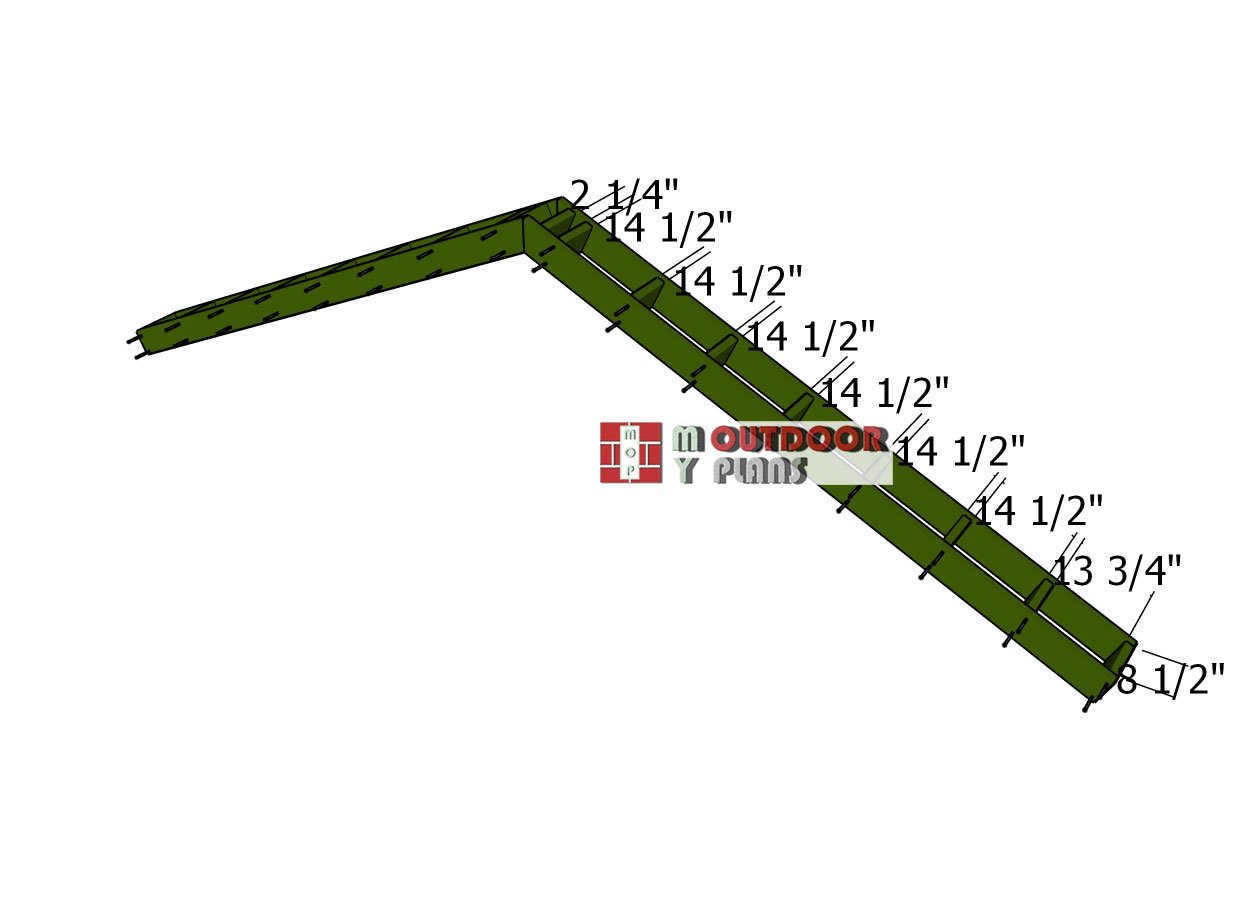

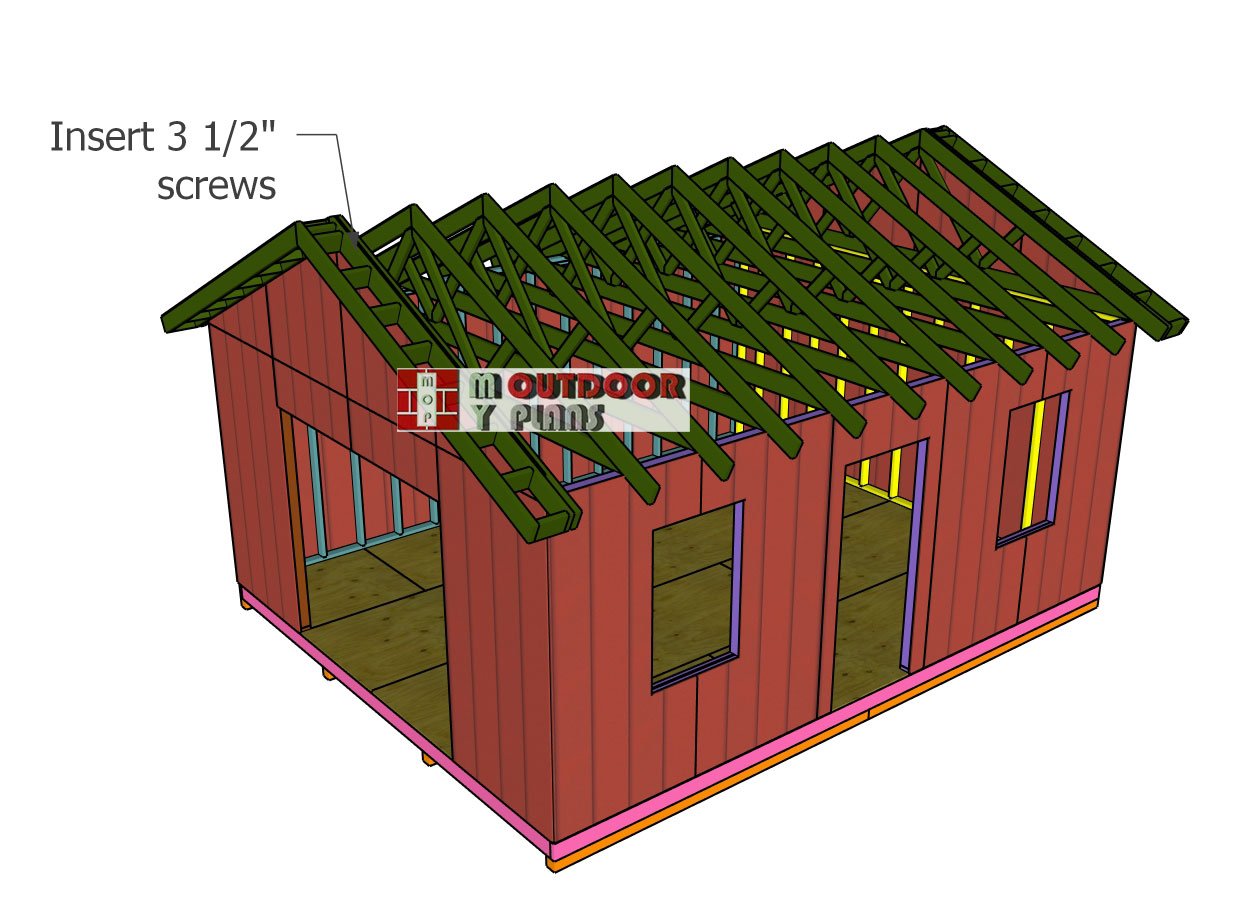

Assembling-the-overhangs

To assemble the overhangs for your gable shed, start by cutting the 2×6 rafters to size, adjusting the dimensions to suit your desired overhang depth. Use a miter saw to make 25-degree angled cuts on one end of each rafter, ensuring they align neatly with the roof’s slope.

Next, cut and fit the 2×6 blocking pieces between the rafters to provide additional stability. Align the blockings evenly and secure them in place using 3 1/2″ screws, creating a rigid structure. Once the rafters and blockings are assembled, attach the overhang structure to the roof frame, using 3 1/2″ screws to lock everything tightly. This design not only adds functionality by protecting the shed walls but also enhances the aesthetic appeal of the shed.

Fitting-the-overhangs

Attach the overhangs to the front and back of the shed, ensuring they are properly aligned and flush with the edges of the roof frame for a clean and uniform appearance. Position the overhangs carefully, checking that they are level and centered.

Drill pilot holes through the overhangs and into the shed’s framing to prevent splitting, then secure them in place using 3 1/2″ screws. Fasten the screws evenly along the length of the overhangs to create a strong and stable connection. This step not only reinforces the roof structure but also adds a professional finish to your shed’s design.

Fitting-the-roof-sheets

To attach 3/4″ plywood sheets to the gable shed roof, start at one lower corner and work your way up, ensuring the first sheet aligns flush with the edge of the roof frame. Lay the plywood perpendicular to the trusses and fasten it using 1 5/8″ screws or nails, spacing them every 8 inches along the edges and 12 inches along the trusses.

Stagger the joints between rows of plywood to increase strength and stability. Drill pilot holes if necessary to prevent splitting, and ensure all edges are supported by trusses for a secure fit. Check that the sheets are flush and properly aligned before moving on to the next row, creating a seamless, solid roof surface.

Side-roof-trims

Attach the 1×8 trims to the sides of the shed roof to complete the finishing touches on the overhangs. Position the trims so their edges are flush with the rafters, ensuring a seamless and professional appearance. Drill pilot holes to prevent splitting, then secure the trims to the rafters using 8d nails, spacing the nails evenly for a neat finish. Double-check the alignment as you work to maintain a consistent look on both sides of the shed. These trims not only enhance the shed’s aesthetic but also provide added protection to the roof edges.

Gable-end-trims

Cut one end of the rafters at a 25-degree angle using a miter saw to match the slope of the roof. Position the rafters at the gable ends of the shed, aligning them flush with the top edge of the roof sheathing for a seamless fit.

Ensure there are no gaps between the rafters and the sheathing to maintain a clean and sturdy finish. Secure the rafters into place by driving 8d nails every 12 inches along their length, fastening them firmly to the roof structure. This step reinforces the roof’s edges and provides a polished look to the shed’s gable ends.

Fitting-the-roofing

Covering your shed with asphalt shingles is a straightforward process that adds durability and a polished look to the roof. Start by installing a layer of tar paper (roofing underlayment) over the plywood sheathing. Begin at the bottom edge of the roof and work your way upward, overlapping each row by at least 2 inches to ensure water flows down and away from the shed. Secure the tar paper with roofing staples or nails, spacing them evenly to hold it securely in place. This underlayment acts as a moisture barrier, protecting your shed from leaks and prolonging the life of the roof. Once the tar paper is installed, attach drip edges along the eaves and rake edges of the roof. These metal strips protect the edges of the plywood from water damage, ensuring a clean finish and improving the overall durability of the roof.

With the tar paper and drip edges in place, you’re ready to lay the asphalt shingles. Begin at the bottom of the roof, starting with a starter strip (a row of shingles with the tabs cut off) to create a base that prevents water infiltration. Lay the first row of shingles over the starter strip, aligning them with the drip edge, and secure them with roofing nails driven just above the tabs. Continue working your way up the roof, staggering the joints between rows to ensure a watertight seal. Use a chalk line to maintain straight rows and cut shingles as needed for the edges and peak. Finally, install ridge shingles along the roof’s peak to cap off the project and give it a finished look. With proper care and installation, your asphalt shingle roof will provide reliable protection for years to come.

Step 4: Double front doors

Door frame

Let’s build those door frames like a pro! Start by cutting 2×4 lumber to size for a sturdy, dependable structure. Drill pocket holes at both ends of the vertical and horizontal pieces to create strong, tight joints. Lay everything out on a flat surface, making sure the corners are perfectly square for a flawless fit.

Once everything is aligned, secure the pieces together by driving 2 1/2″ screws into the pocket holes. This technique ensures a rock-solid frame that’s built to last, ready to support your shed doors and handle the demands of everyday use.

Double-door-panel

Remember those panels you cut out for the front wall siding? It’s time to put them to work! Attach the panels to the door frames, making sure they’re aligned perfectly for a clean, professional look. Secure them in place by driving 8d nails evenly along the edges, locking everything together tightly.

This step not only gives your doors a polished finish but also adds strength and durability to handle whatever comes their way.

Double-door-jambs

Let’s get those door jambs installed! Grab your 2x4s and attach them around the door opening, aligning the edges so they’re perfectly flush. Drill pilot holes to prevent splitting, then secure the jambs in place with 3 1/2″ screws.

Space the screws every 8″ along the framing for a strong, tight fit. This step not only ensures a secure door installation but also gives the opening a clean, finished appearance.

Fitting-the-double-doors

It’s time to hang those double doors and bring your shed to life! Fit the doors into the opening, making sure they align evenly with the jambs for a smooth, professional finish. Secure the doors to the jambs using heavy-duty hinges—spacing them evenly along the edges for maximum support.

Don’t forget to install a sturdy latch to keep your doors secure and your belongings safe. With this final touch, your shed is ready to handle whatever you need to store.

Step 5: Side door

Shed-door-frame

Assemble the side door from 2×4 lumber, using 2 1/2″ screws and pocket holes. Use the instructions in the previous step.

Door-panel

Attach the cutout panel to the door frame. Use 8d nails to secure the panel to the door frame.

Side-door-jambs

Fit the 2×4 jambs around the door opening with 3 1/2″ screws.

Fitting-the-side-door

Attach the door into place with hinges and a latch.

Attaching-the-window-trims

Attach the windows to the openings and secure them to the frame with appropriate techniques, as described in the manufacturer’s instructions. Fit the decorative trims into place.

Step 6: Finishing touches

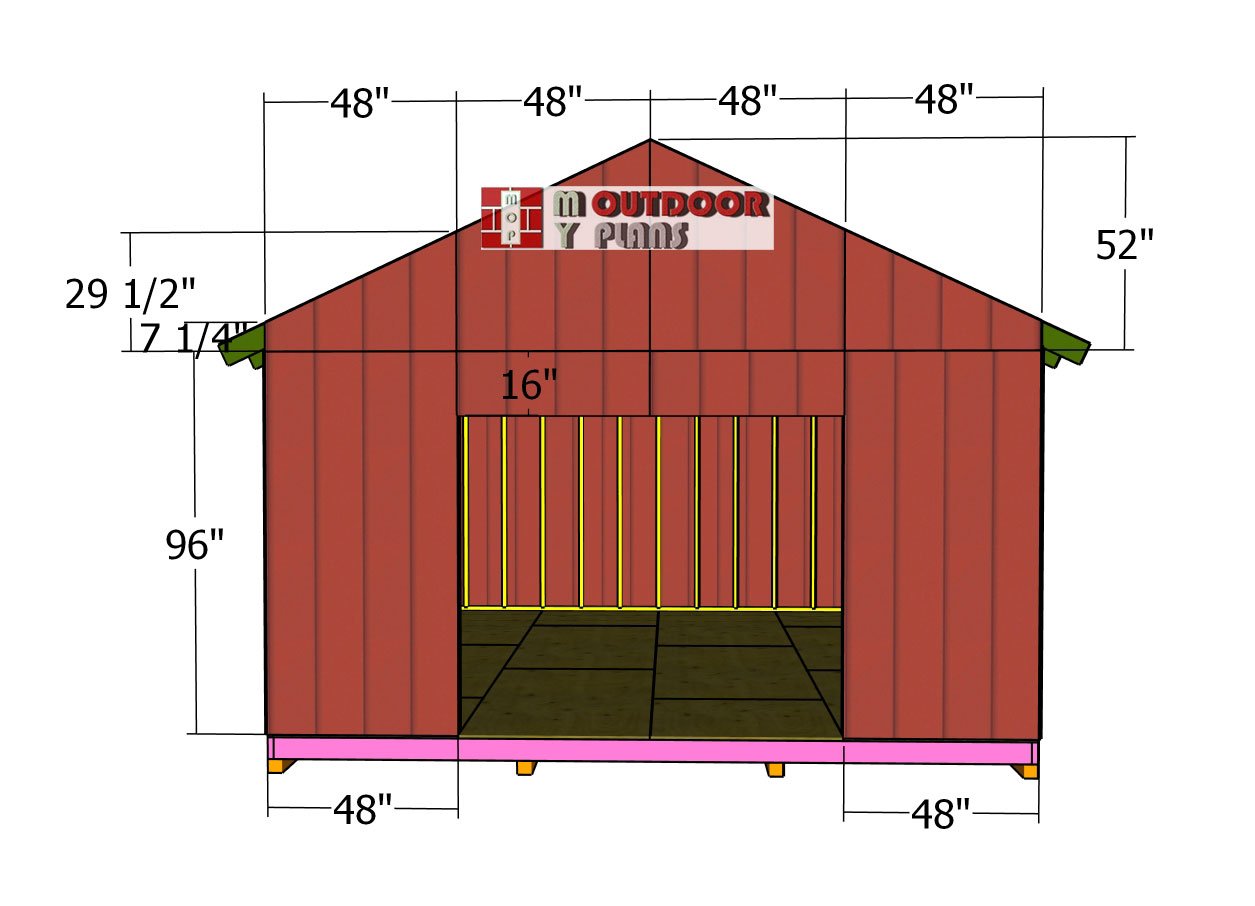

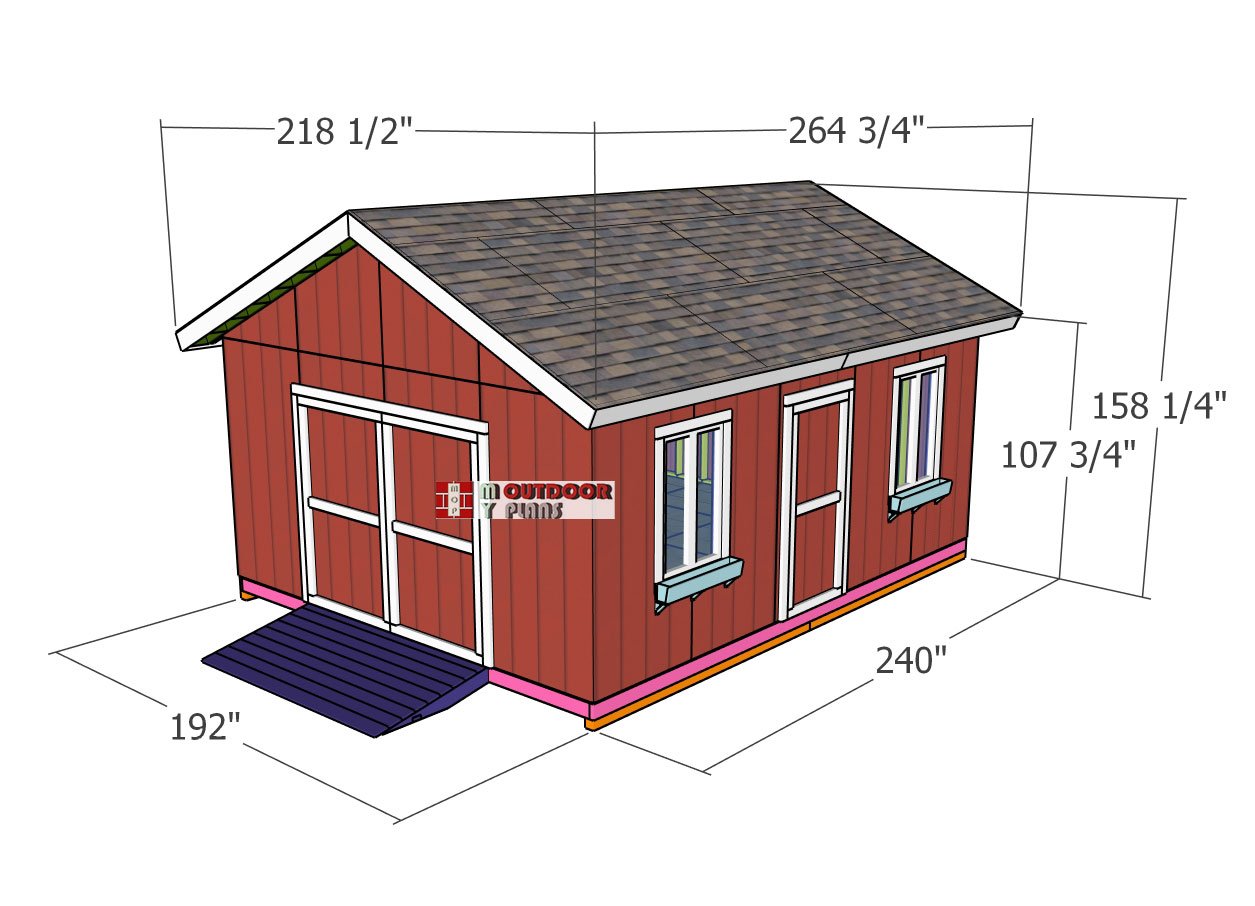

16×20-gable-shed—dimensions

The finishing touches are what truly bring your shed to life and ensure its functionality and charm. Start by painting or staining the exterior to protect the wood and enhance the shed’s appearance, choosing a color that complements your home or garden.

Install trim around doors and windows for a polished look, and add hardware like handles and hinges to complete the doors. Seal any gaps with caulk to prevent drafts and water intrusion, and consider adding gutters to manage rainwater runoff. Inside, you can install shelves or hooks for storage and even add insulation or lighting if you plan to use the shed year-round. These final details transform your shed into a durable, attractive, and versatile space.

How to build a 16×20 shed

In the PREMIUM PLANS I show you how to build the planter boxes and the front ramp. In addition, the PREMIUM PLANS come with CUT LAYOUT Diagrams, showing how to cut the parts for your shed from the shopping list, in such a way you get minimal waste.

In PART 1, we talk about how to build the frame of the shed. Check it out, as well.

This woodworking project was about 16×20 gable shed plans. If you want to see more outdoor plans, check out the rest of our step by step projects and follow the instructions to obtain a professional result.