This step by step diy woodworking project is about sawhorse table plans. Building a nice and unique woodworking table is a great idea, especially if you want to add value to your yard. Don’t forget that you should adjust the size and the design of the table to suit your needs and budget. Work with attention and check out the rest of the related projects, in order to get several ideas for your woodworking venture.

On the other hand, we consider that you should invest in the best materials you can afford, in order to get the job done as a professional. Cedar, pine and redwood are great choices, as they have a nice finish and are highly durable. Plan every aspect of the project from the very beginning, in order to prevent costly mistakes. Always pre-drill the components before inserting the screws to prevent the wood from splitting. Rounding the edges of the exterior slats is not compulsory, but it will most certainly add value to your project. Mark the cut lines with a pencil and get the job done with a jigsaw. See all my Premium Plans HERE.

Projects made from these plans

Cut & Shopping Lists

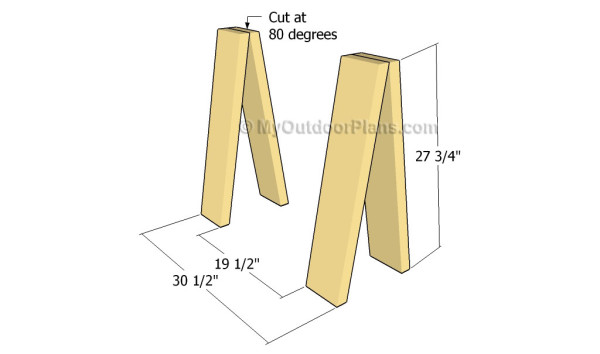

- A – 8 pieces of 1×6 lumber – 27 3/4″ long (both ends cut at 80 degrees) LEGS

- B – 4 pieces of 2×4 lumber – 8 1/2″ long, 2 pieces – 23 1/2″ long, 1 piece – 59″ long SUPPORTS

- C – 2 pieces of 2×4 – 38 1/2″ long SUPPORTS

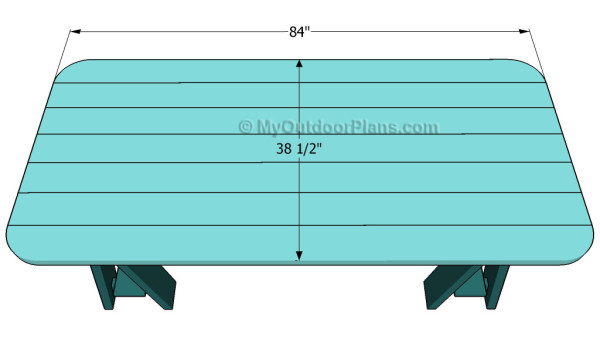

- D – 7 pieces of 2×6 – 84″ long TABLETOP

Tools

![]() Hammer, Tape measure, Framing square, Level

Hammer, Tape measure, Framing square, Level

![]() Miter saw, Drill machinery, Screwdriver, Sander

Miter saw, Drill machinery, Screwdriver, Sander

Time

Related

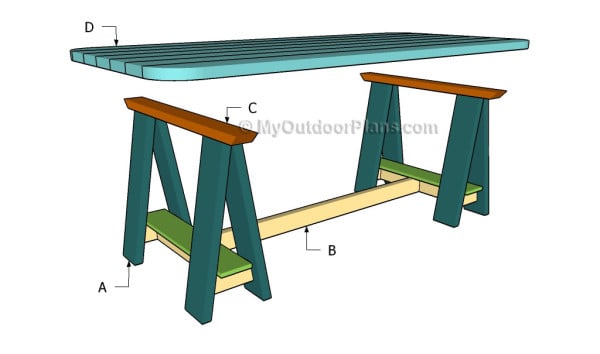

Building a sawhorse table

Building the sawhorse table

Top Tip: Building a nice wooden table for your garden is a good idea, especially if you are going for an unique design. Don’t forget to check out the rest of the table plans before starting the woodworking project.

Sawhorse table plans

Building the saw horses

The first step of the woodworking project is about how to build the sawhorses. In order to get the job done in a professional manner, we recommend you to use 1×6 lumber for the sawhorses.

Top Tip: Cut both ends of the 1×6 slats at about 80 degrees, if you want to get a proper angle for the table legs. Smooth the cut edges with a piece of sandpaper, if you want to get a professional result and clean edges.

Attaching the supports

The next step of the project is to attach the 2×4 supports into place, as shown in the plans. If you want to get a neat appearance, we recommend you to cut both ends of the supports at about 45 degrees.

Top Top: Align the supports at both ends and lock them to the legs with waterproof glue and screws. Drill pocket holes at the top of the legs before inserting the galvanized screws into place.

Fitting the supports

Continue the woodworking project by attaching the braces to the bottom of the sawhorses. Cut both ends of the small braces at about 80 degrees and lock them into place with screws. Drill pocket holes at both ends of the supports and braces and use 2 1/2″ screws to lock everything together.

Top Tip: Next, lock the sawhorses together by fitting a 2×4 wooden stretcher into place. Before locking the stretcher into place, we recommend you to check if it is perfectly horizontal by using a spirit level.

Attaching the bottom shelves

If you want to enhance the utility of the table, we recommend you to create small shelves at the bottom of the sawhorses. Fit 1×6 slats to the bottom of the braces and lock them into place with 1 1/4″ finishing nails.

Installing the tabletop

Next, build the tabletop components and to lock them into place with screws. If you want to get the job done in a professional manner, we recommend you to to use 2×6 slats.

Place the slats over the sawhorses and make sure there are no gaps between them. Add waterproof glue between the slats and clamp them together with several C-clamps. Lock the slats to the supports with 2 1/2″ galvanized screws, from the bottom into the slats.

Sawhorse table plans

One of the last steps of the woodworking project is to take care of the finishing touches. Therefore, fill the pilot holes with wood putty and smooth the surface with 120-grit sandpaper.

Top Tip: In order to protect the lumber from water damage, we recommend you to cover the components with several coats of paint. Place the wooden sawhorse table in a proper location and move it whenever necessary.

This woodworking project was about sawhorse table plans. If you want to see more outdoor plans, we recommend you to check out the rest of our step by step projects. LIKE us on Facebook and Google + to be the first that gets out latest projects.